Indium powder manufacturing system

A technology of indium powder and gas, applied in the field of indium powder preparation system, can solve the problems of hindering the industrial scale of indium powder, low output rate of indium powder, high production cost, etc., and achieve simple structure, low production cost and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

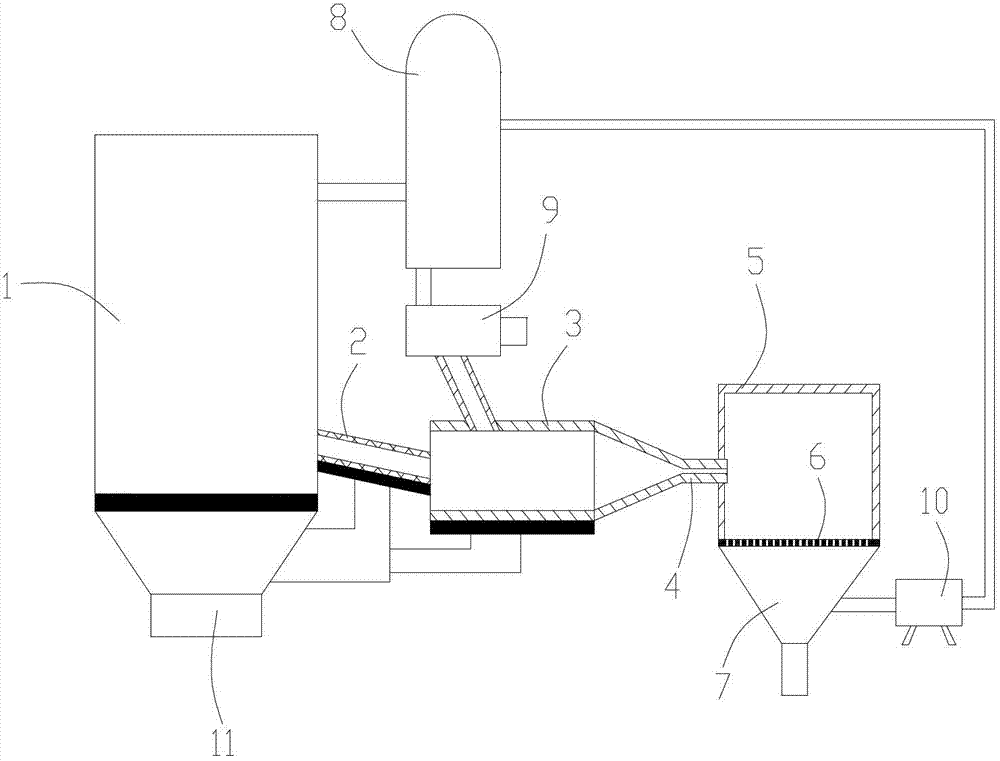

[0013] Combine below figure 1 The present invention is described in further detail:

[0014] The present indium powder production system includes a melting pool 1 for liquefied metal indium raw materials. The lower side of the melting pool is provided with a guide tube 2 for leading out liquid indium. The guide tube communicates with a horizontally arranged injection chamber 3. The injection chamber The right end is equipped with a nozzle 4, the nozzle extends into an atomization chamber 5, a screen 6 is installed at the bottom of the atomization chamber, and a dust collector 7 is connected to the lower part of the screen, the dust collector collects the indium powder particles below the screen, and The indium powder particles above the screen can be recycled to the melting pool for further refinement. The present invention does not need to heat the metal indium above 2000 DEG C to make it into indium vapor, but only needs to heat the molten pool above the melting point of in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com