Method for manufacturing fiber reinforced plastic plate type spring

A fiber reinforced plastic, leaf spring technology, applied in the coating and other directions, can solve the problems of low spring fiber content, small spring adaptability, uneven resin distribution, etc., and achieve the effects of small deformation, improved efficiency, and uniform fiber distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

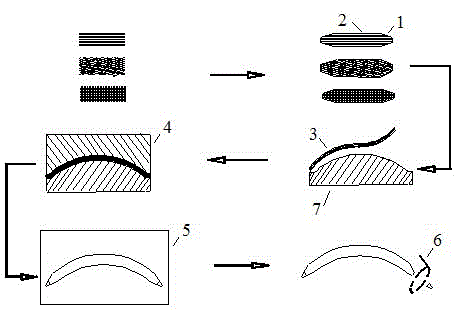

[0071] A method for manufacturing a fiber-reinforced plastic leaf spring, at least including: prepreg, cutting, layering, thermoforming, and post-treatment processes (see attached figure 2 shown). The specific production steps are as follows:

[0072] Prepreg: The matrix of unidirectional or bidirectional fiber prepreg is any one of polyester, vinyl resin and epoxy resin, and the reinforcing fiber is any one or several of glass fiber, carbon fiber and organic fiber. where unidirectional 0 o The fiber mass fraction in the fiber direction prepreg is 50%-80%, and the fiber surface density is 800g / m 2 -2500g / m 2 ;Two-way fiber prepreg is ±45 o Fiber direction or 0° / 90° fiber direction prepreg, fiber mass fraction 50%-80%, fiber surface density 400g / m 2 -2500g / m 2 . The fibers in the above prepreg are continuous without being cut.

[0073] Cutting process: 0 o Fiber direction prepreg and 0° / 90° fiber direction prepreg along 0 o The fiber direction is cut, and 0 o Fiber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com