Internal combustion heating device of coal pyrolyzing furnace

一种加热装置、内燃烧的技术,应用在炼焦炉的加热、可燃气体加热炼焦炉、燃烧室等方向,能够解决不能进行连续生产、生产效率低下、没荒煤气导出、回收净化利用等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

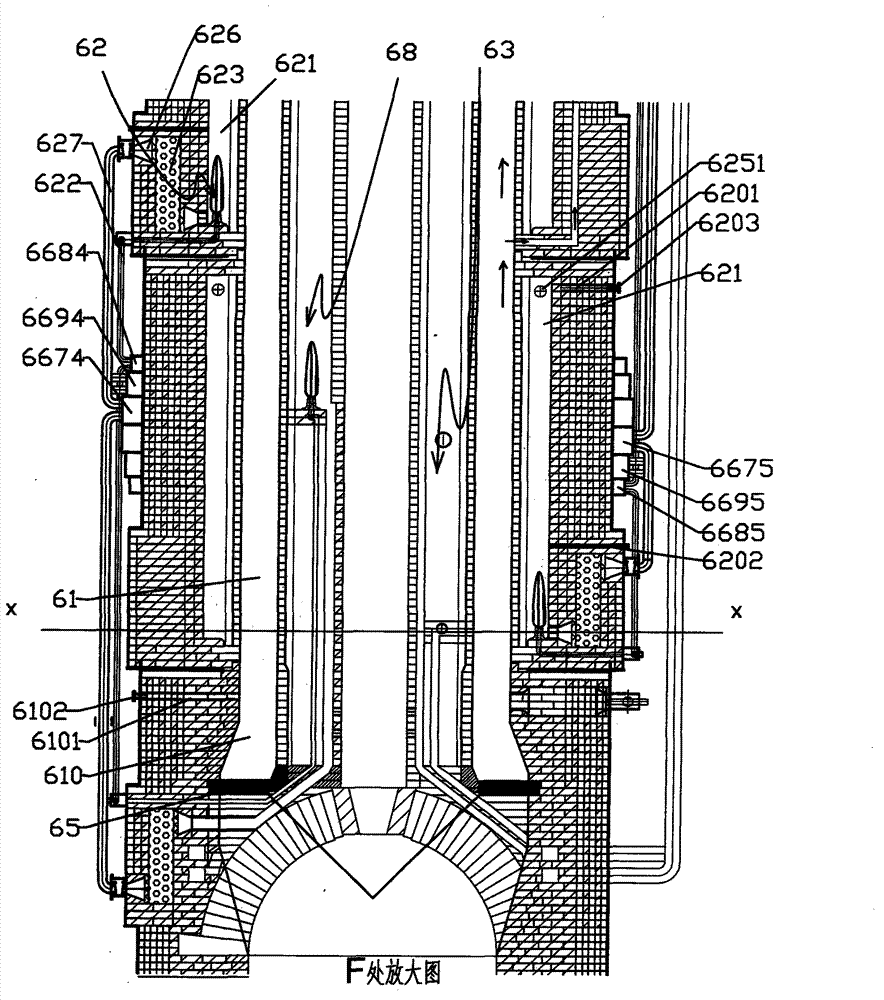

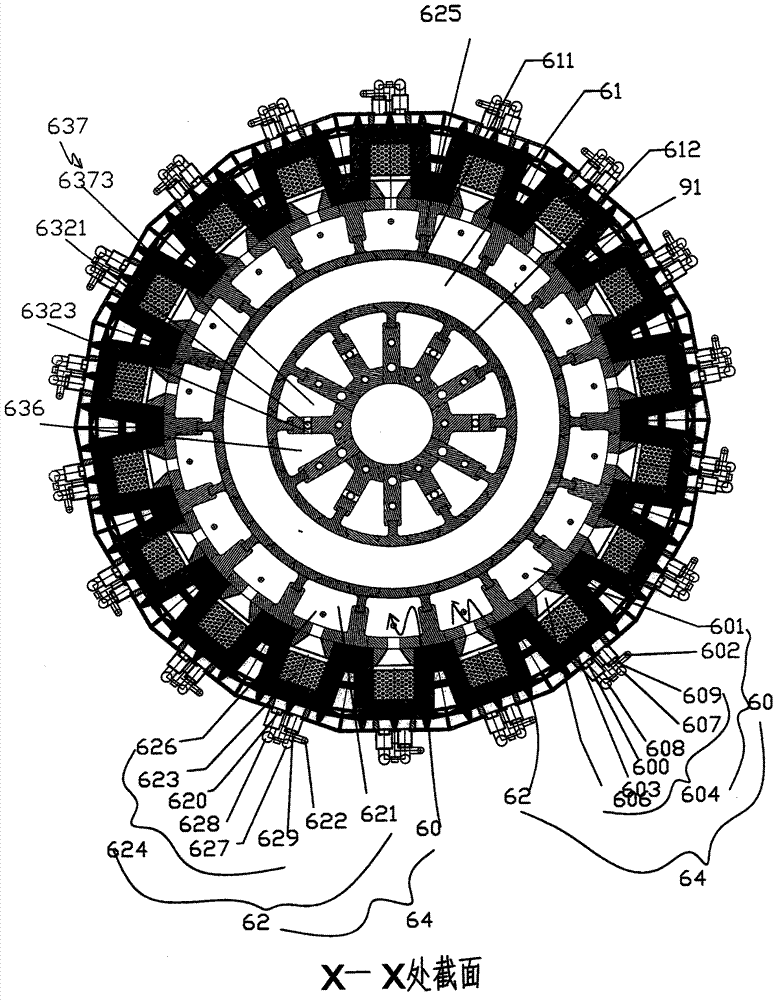

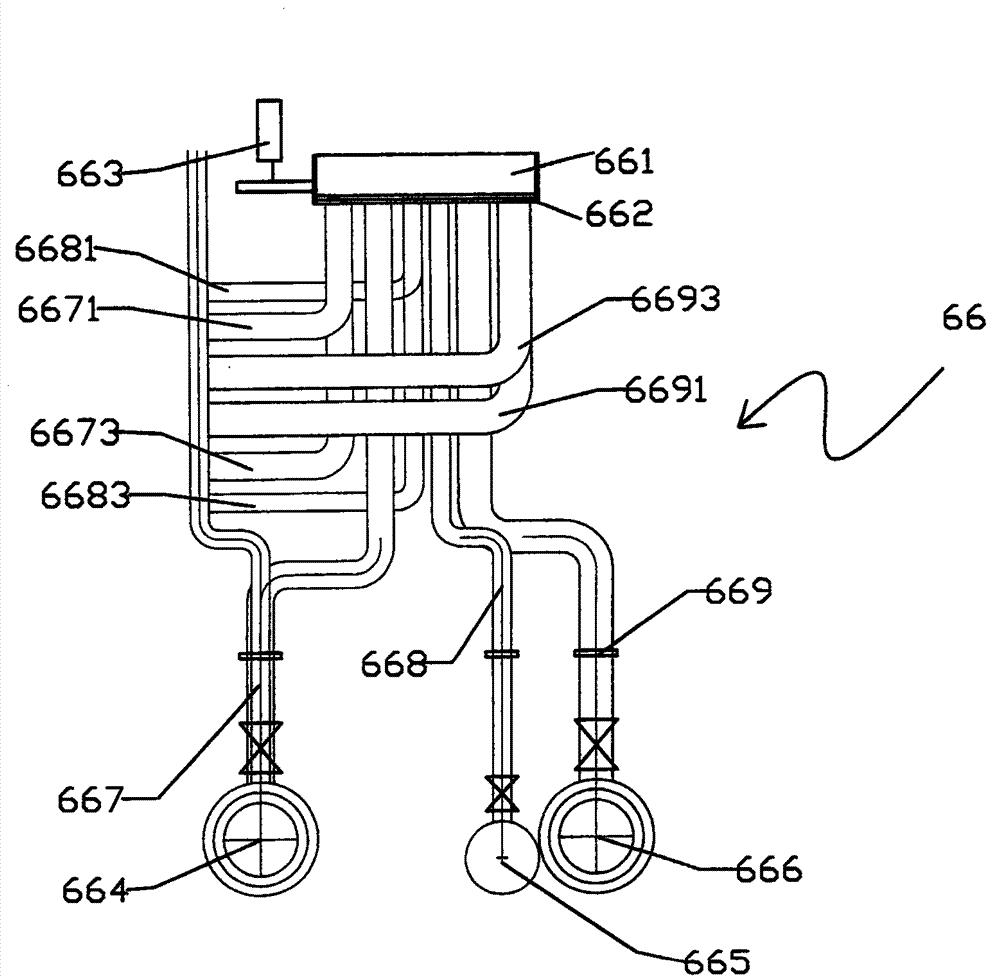

[0028] The specific embodiment of the combustion heating device in the coal pyrolysis furnace of the present invention is mainly introduced in detail in the first section of the fourth part below.

[0029] Part 1 Furnace Coal Proportion and Preparation

[0030] Such as selecting 5 kinds of different coals, they are respectively gas coal, fat coal, coking coal, one-third coking coal, and lean coal are first mixed and then sieved and crushed to form coal into the furnace. Of course, the coal pyrolysis furnace of the present invention is the same for other proportions. Applicable, and does not constitute a restriction on the coal powder required for the coal pyrolysis furnace of the present invention.

[0031] The second part of coal dehydration

[0032] The incoming coal entering the coal pyrolysis furnace is dehydrated in advance through the incoming coal dehydration device, which plays the role of saving energy and reducing consumption.

[0033] The third part into the furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com