Ion-absorbing type rare earth in-situ mineral leaching mother liquor recovery process

An ion adsorption type and mother liquor recovery technology, applied in the direction of improving process efficiency, etc., can solve problems such as easy landslides, excessive discharge of waste soil, environmental pollution, etc., so as to ensure the quality of engineering construction and reduce the discharge of waste soil , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

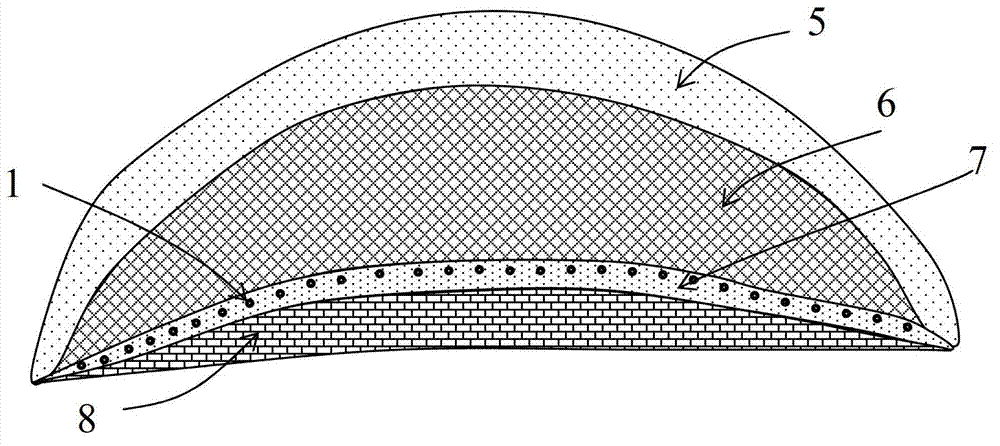

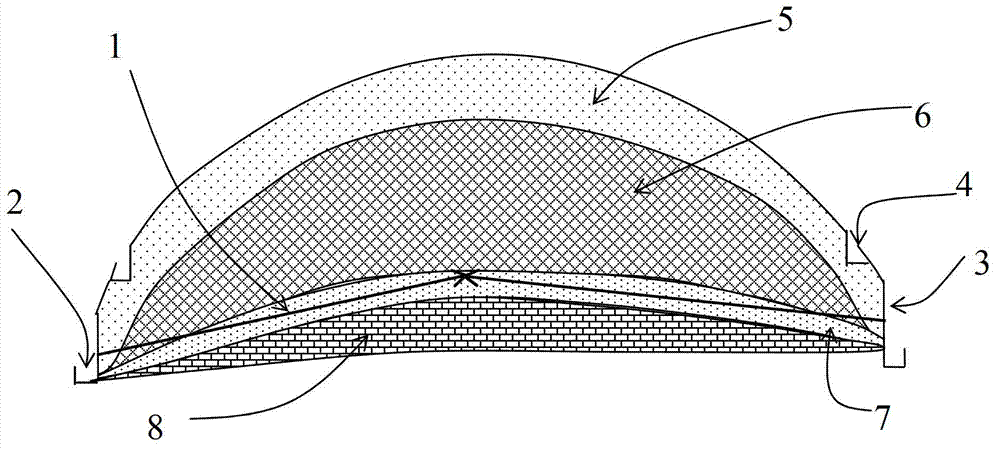

[0020] exist figure 2 , reference numeral 5 shows a clay layer. Reference numeral 6 shows an ore body. Reference numeral 7 shows a mineral-free zone.

[0021] The invention provides an ion-adsorption type rare earth in-situ leaching mother liquor recovery process, which is based on the permeability of the ore soil, the local water level, the distance between the bottom of the ore body and the bedrock 8, and considering the water content of each part in the production process of the ore block. Factors such as the dynamic change of the rate on the mountain surface (mountainside or mountain foot) select an appropriate position, that is, determine the position of the diversion hole construction on the control surface of the rare earth mother liquor recovery project; according to the selected position, implement an artificial steep slope 3 of 30-100 cm, Provide a construction plane for the next step using a hydraulic drilling rig or a high-pressure water gun.

[0022] According...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com