Recycling method of raffinate during vanadium extraction from stone coal

A technology for raffinate and stone coal is applied in the field of recycling of vanadium raffinate extraction from stone coal, which can solve the problems of waste of resources, large lime, inability to recover, etc., and achieve the effect of saving treatment costs and low costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

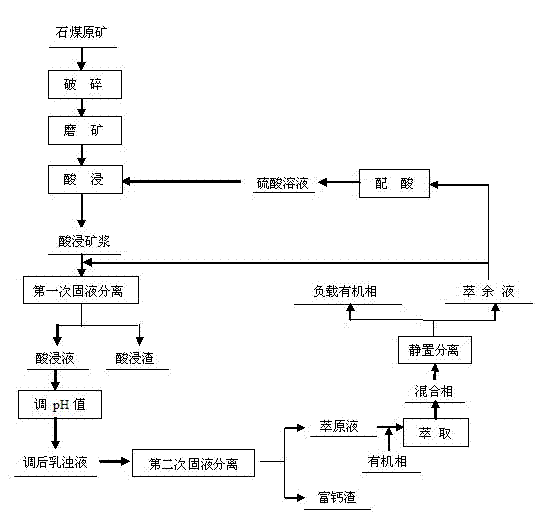

[0023] A method for recycling the raffinate of vanadium extraction from stone coal. Its specific steps are:

[0024] (1) The stone coal raw ore is acid-leached with sulfuric acid solution after being crushed and ground to obtain acid-leached pulp; The immersion time is 4~6 hours, and the liquid-solid mass ratio of acid leaching is (1.5~2):1;

[0025] (2) Carry out solid-liquid separation for the first time with acid leaching pulp, obtain acid leaching liquid and acid leaching residue;

[0026] (3) Use milk of lime to adjust the pH value of the pickling solution to 1.5-2.0 to obtain the adjusted emulsion, and then perform a second solid-liquid separation on the adjusted emulsion to obtain the original solution and calcium-rich slag;

[0027] (4) extract the raw liquid with the organic phase to obtain the mixed phase, and then separate it by standing to obtain the loaded organic phase and raffinate;

[0028] (5) First use the raffinate to prepare acid, and the prepared sulfur...

Embodiment 2

[0031] A method for recycling the raffinate of vanadium extraction from stone coal. Its specific steps are:

[0032] (1) The stone coal raw ore is acid-leached with sulfuric acid solution after crushing and grinding to obtain acid-leached pulp; the acid-leaching conditions are: the volume concentration of sulfuric acid solution is 15-20%, the acid-leaching temperature is 95-100°C, and the acid-leaching pulp is obtained. The immersion time is 3~5 hours, and the liquid-solid mass ratio of acid leaching is (1~1.5):1;

[0033] (2) Carry out solid-liquid separation for the first time with acid leaching pulp, obtain acid leaching liquid and acid leaching residue;

[0034] (3) Use milk of lime to adjust the pH value of the pickling solution to 2~2.5 to obtain the adjusted emulsion, and then perform a second solid-liquid separation on the adjusted emulsion to obtain the original solution and calcium-rich slag;

[0035] (4) extract the raw liquid with the organic phase to obtain the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com