Tool and method for injecting cement into top of horizontal well screen pipe without drilling and plugging

A drilling plug-free and cementing technology, which is applied in wellbore/well components, earthwork drilling, production fluids, etc., can solve the problem of wear or damage of grading hoops and casings, affecting production and operating tools, and destroying drill plugs Problems such as cement sheath can be solved to achieve the effect of saving completion cost, improving operation effect and improving construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

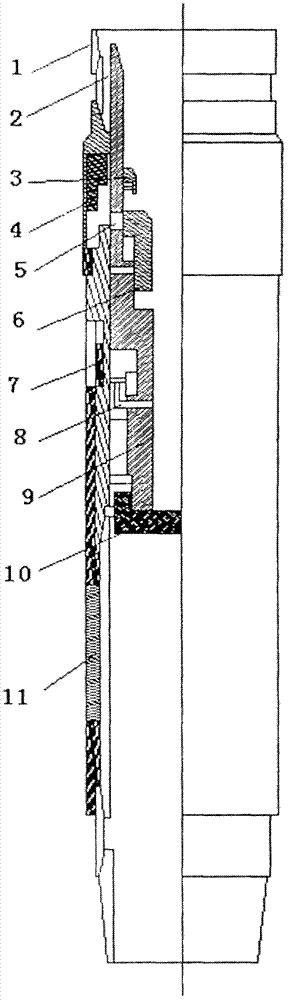

[0032] The present invention will be further described now in conjunction with the accompanying drawings of the description.

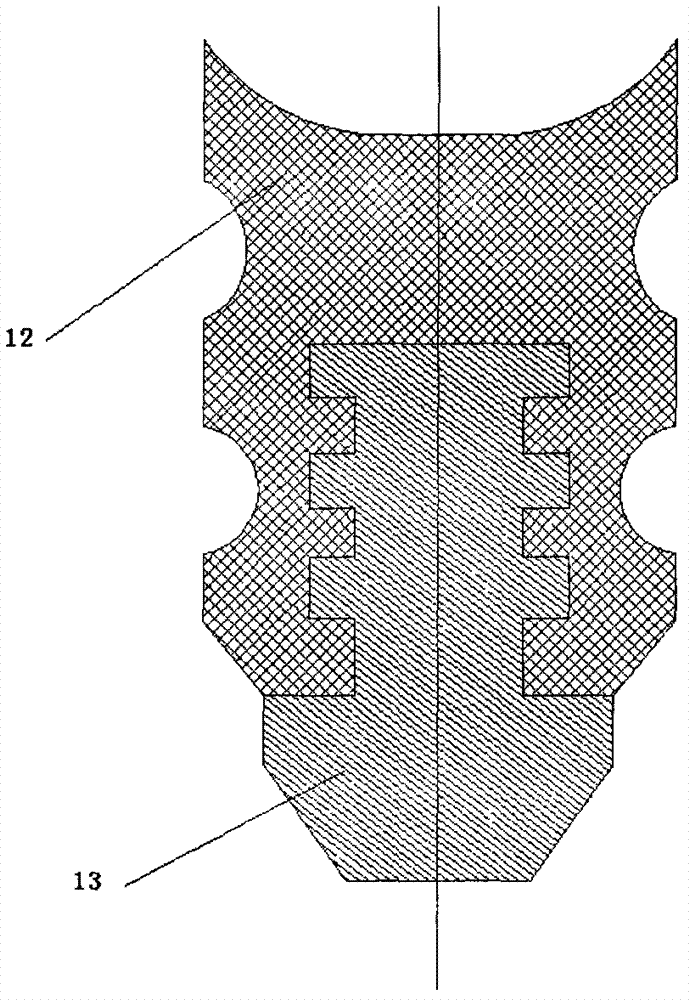

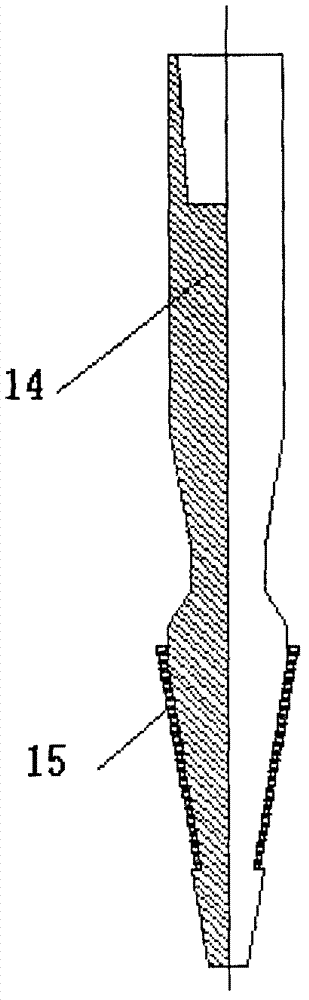

[0033] Refer to the accompanying drawings in the manual figure 1 , The tools for cementing the top of the horizontal well screen pipe without drilling plugs are composed of bumper rubber plugs, fishing tools and drilling plug-free tools. The upper part of the body 13 of the bumper rubber plug is wrapped with rubber 12, and the periphery of the rubber 12 is processed into a concave arc shape, and the upper surface is arc-shaped, which can be sealed with the inner wall of the overshot; the lower part of the body 13 is inverted conical, and the rubber plug seat 3 Mates to form a face seal. The body is made of an easy-to-drill material, such as aluminum. The top of the fishing tool is a round rod-shaped fishing anchor 14 equal in diameter to the small drill pipe, and the fishing buckle is arranged to be connected with the drill pipe. The lower head of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com