Electromagnetic paraffin-inhibiting viscosity reducer

An electromagnetic anti-waxing and viscosity-reducing technology, which is used in cleaning equipment, wellbore/well components, and earth-moving drilling and mining, etc., can solve the problem that the electromagnetic anti-waxing and viscosity-reducing device is not versatile enough, cannot be adjusted for changes, and the sealing material is easy to fail. and other problems, to achieve the effect of prolonging the pump inspection and pipeline wax cleaning cycle, preventing wax precipitation, and improving oil production and pipeline transportation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

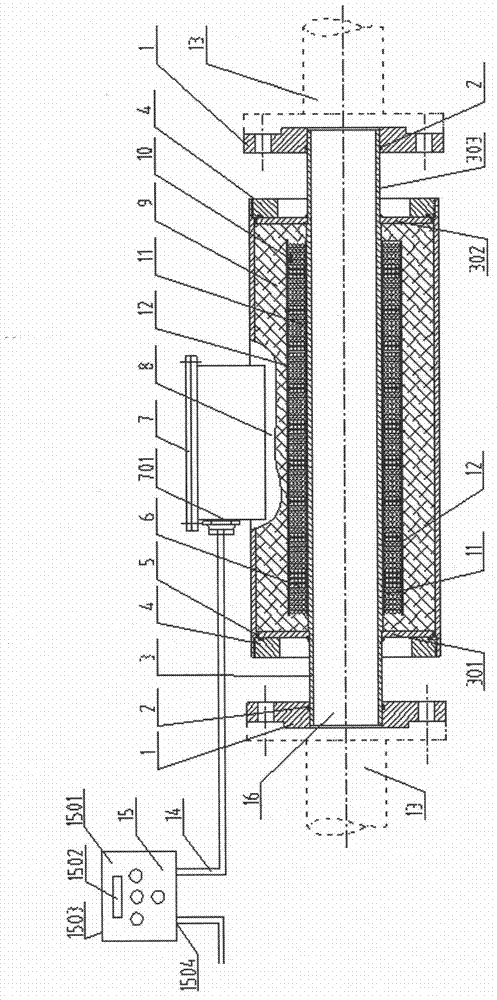

[0021] figure 1 It is a schematic diagram of an electromagnetic wax-preventing viscosity reducer provided by the present invention. The electromagnetic wax-prevention viscosity reducer includes a magneto-thermal generator 16 , and the power control box 15 is connected to the magneto-thermal generator 16 through a cable 14 .

[0022] The power control box 15 is composed of a power conversion control circuit board 1501 installed in the electric box shell 1503 , a control display panel 1502 , and wiring terminals 1504 inside the box. The terminal 1504 in the box is connected to one end of the cable 14 , and the control display panel 1502 is connected to the terminal 1504 in the box through the power conversion control circuit board 1501 .

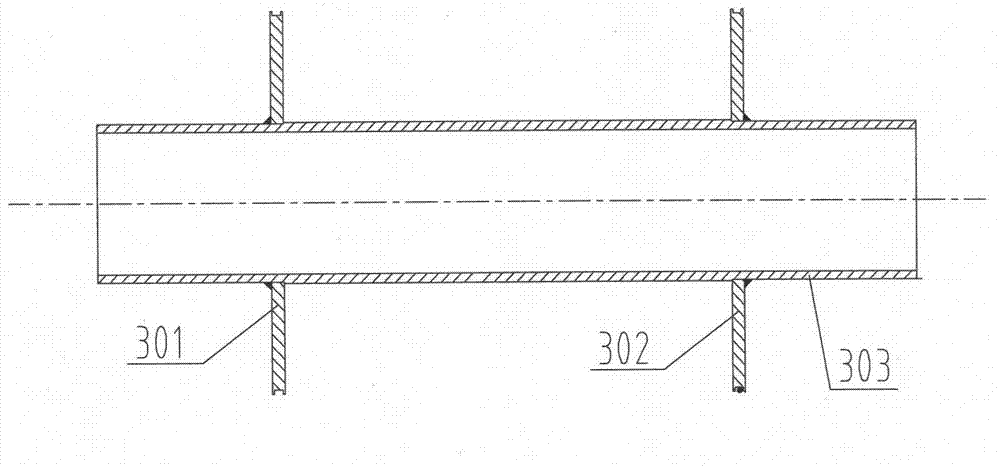

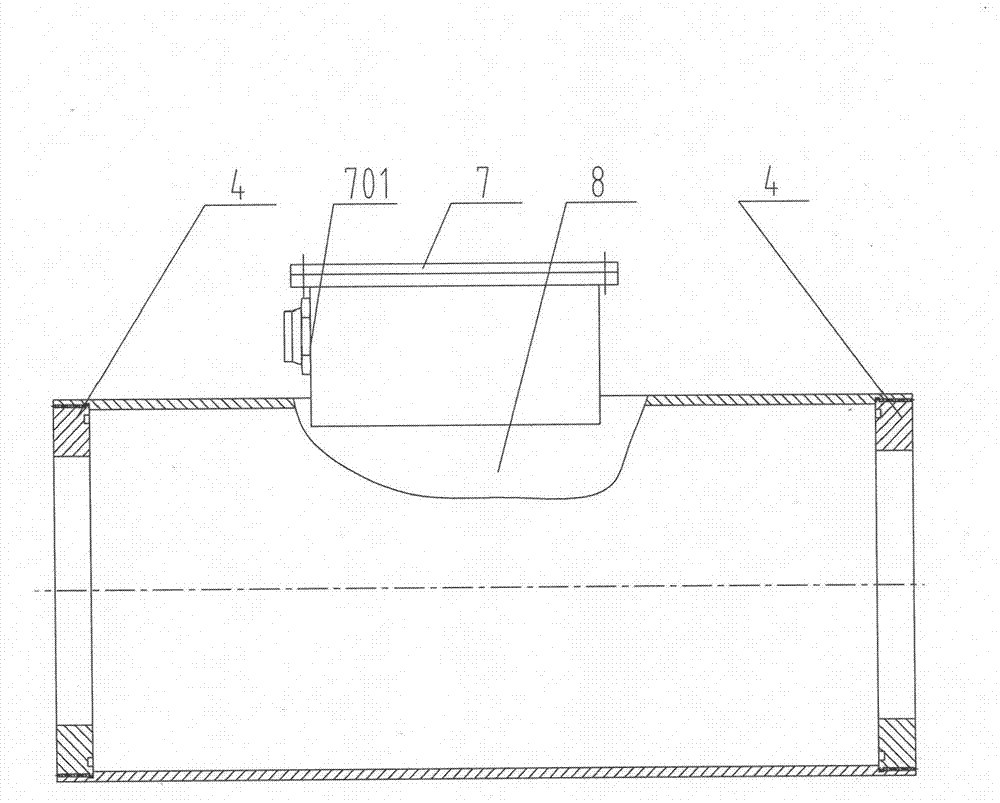

[0023] The magnetic heat generating device 16 includes an inner tube 3, and the coil 6 is wou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com