Furnace drying method of industrial furnace module and furnace drying device for industrial furnace module

A furnace method and industrial furnace technology, applied in the direction of furnace, electric furnace heating, furnace components, etc., can solve the problems affecting the final quality of the lining, uneven drying, difficult to meet the temperature rise rate requirements, etc., to avoid cracks or deformation of the furnace wall damage, save operating costs and time, and shorten the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

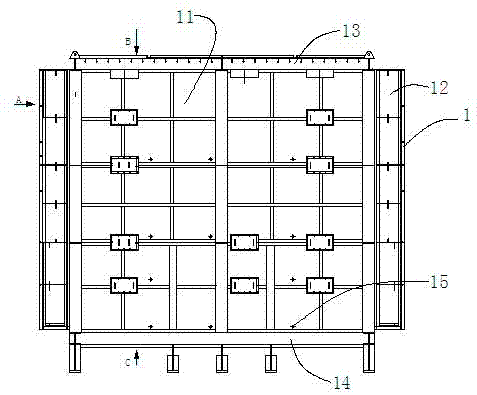

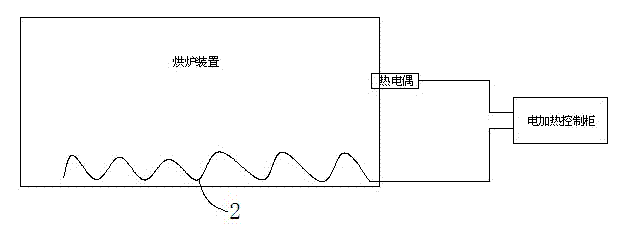

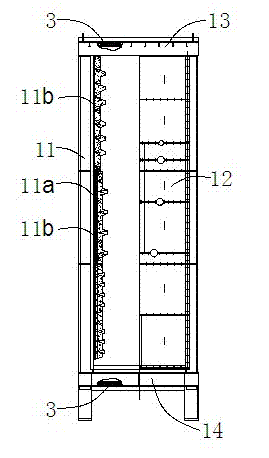

[0030] Figure 1 to Figure 5 Shown is the structural representation of the present invention.

[0031] The reference signs are: industrial furnace module 1, industrial furnace module side wall 11, backing layer 11a, castable layer 11b, elbow box 12, furnace top smoke hood 13, furnace base 14, thermocouple socket 15, Electric heating assembly 2, insulation layer 3, exhaust hole 4.

[0032] The oven method of industrial furnace module of the present invention adopts electric heating to carry out oven, specifically comprises the following steps:

[0033] ①The lining of industrial furnace module 1 has been poured and cured, and the acceptance is qualified;

[0034] ②The industrial furnace module 1, the sealed furnace base 14 and the furnace top hood 13 are installed, and the sundries in the furnace are cleaned up and accepted;

[0035] ③The cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com