System for cleaning with rubber balls

A cleaning system and rubber ball technology, applied in the field of rubber ball cleaning system, can solve the problems of low efficiency, complicated operation, high failure rate of water pump and shortened life span, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

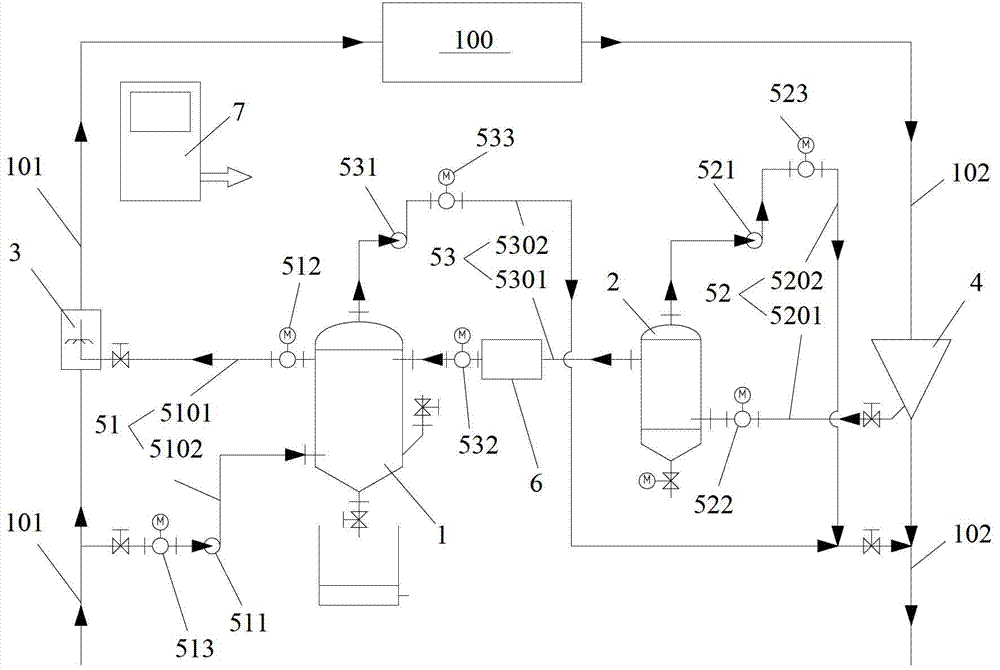

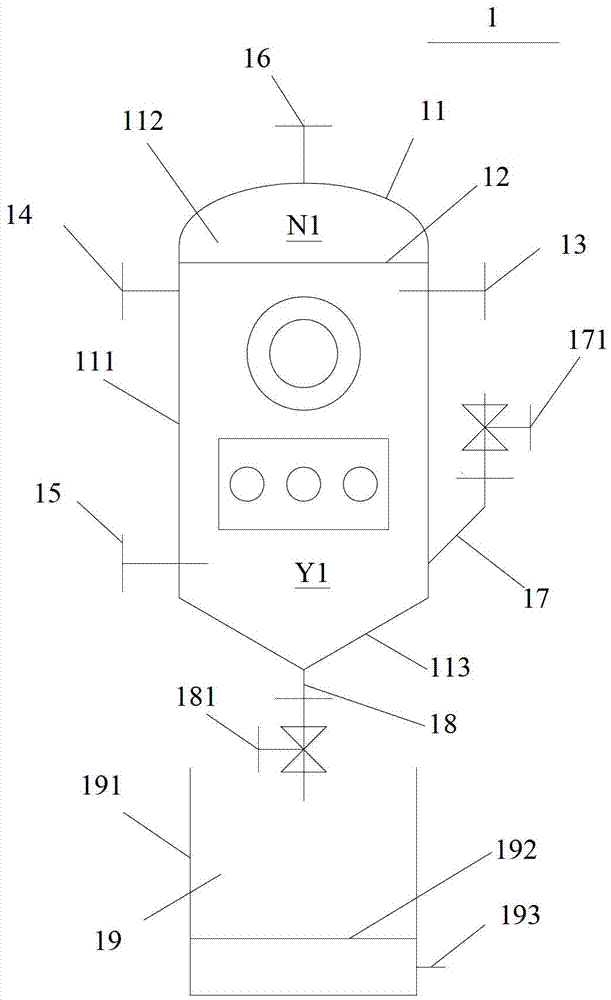

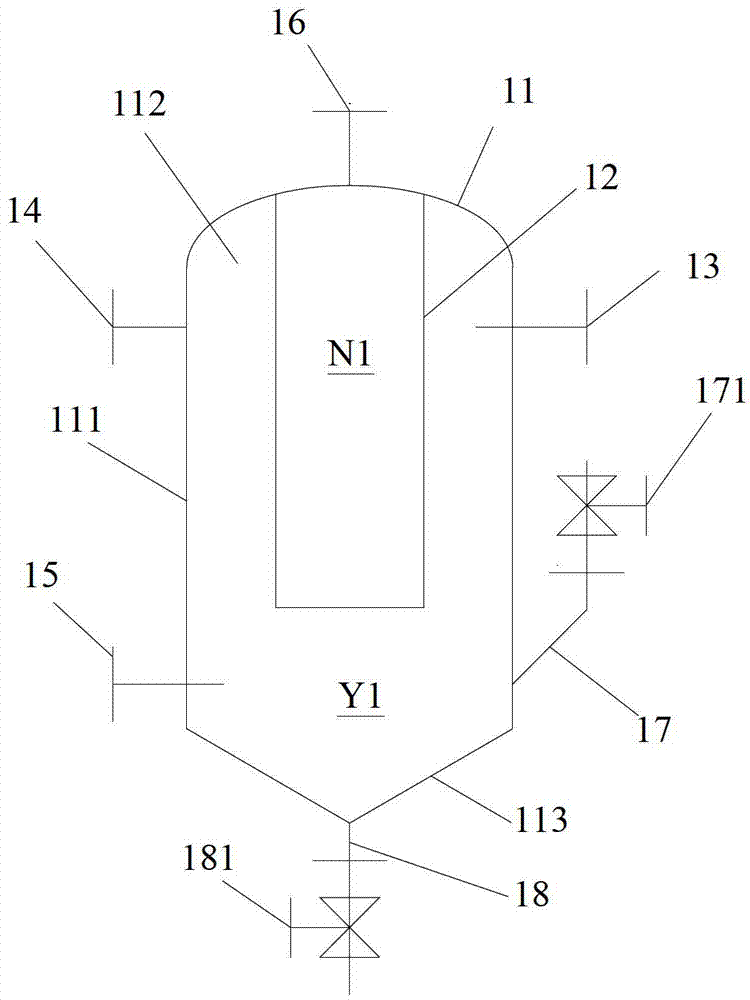

[0056] figure 1 is a schematic diagram of the rubber ball cleaning system provided by the first embodiment of the present invention, figure 2 and image 3 yes figure 1 A schematic structural view of the first ball storage device 1 in the shown rubber ball cleaning system, Figure 4 yes figure 1 The structural representation of the second ball storage device 2 in the shown rubber ball cleaning system, Figure 5 yes figure 1 The connection block diagram of the rubber ball cleaning function piping system in the rubber ball cleaning system shown.

[0057] Such as Figure 1 to Figure 5 As shown, in the first embodiment of the present invention, the rubber ball cleaning system includes rubber ball cleaning functional equipment and rubber ball cleaning functional piping system, and the rubber ball cleaning functional equipment includes a first ball storage device 1, a second ball storage device 2. The ball throwing device 3 and the rubber ball collection device 4, etc., the r...

no. 1 example

[0157] Figure 6 and Figure 7 A modification of the gum ball cleaning system in the first embodiment is shown. Figure 6 The rubber ball cleaning system in figure 1 The rubber ball cleaning systems in the two are basically the same, and the following will only describe the differences between the two, and will not repeat them for the same parts.

[0158] Such as Figure 6 and Figure 7 As shown, a second pitching pipeline 5102 is connected between the water inlet connecting pipe 15 and the input pipeline 101, and the second pitching pipeline 5102 is provided with a second pitching control valve 513 and a pitching water pump 511. Preferably, the pitching water pump 511 is located at The downstream side of the second pitch control valve 513 . A second ball collection pipeline 5202 is connected between the drain connecting pipe 16 and the output pipeline 102. The second ball collection pipeline 5202 is provided with a ball collection water pump 521 and a second ball collect...

no. 2 example

[0166] Figure 8 It is a schematic diagram of the rubber ball cleaning system provided by the second embodiment of the present invention.

[0167] Such as Figure 8 As shown, the second embodiment of the present invention provides a rubber ball cleaning system, the rubber ball cleaning system includes a rubber ball cleaning functional device and a rubber ball cleaning functional pipeline system, the rubber ball cleaning functional device includes a first ball storage device 1. The second ball storage device 2, the ball throwing device 3 and the rubber ball collecting device 4, etc., the rubber ball cleaning function pipeline system 5 includes a ball throwing pipeline 51, a ball collection pipeline 52 and a ball switching pipeline 53, etc., and the ball throwing pipe Road 51 and switching ball pipeline 53 share a pitching and switching ball common pipeline. The rubber ball cleaning function pipeline system connects the input / output pipeline of the equipment to be cleaned with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com