Device and method for adjusting tilt of measured mirror in matching measurement of flat sub-aperture

A technology of splicing sub-apertures and mirrors under test, which is applied in the field of optical testing, can solve problems such as large fitting errors of tilt coefficients and poor splicing results, and achieve the effects of high precision, simple structure and algorithm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

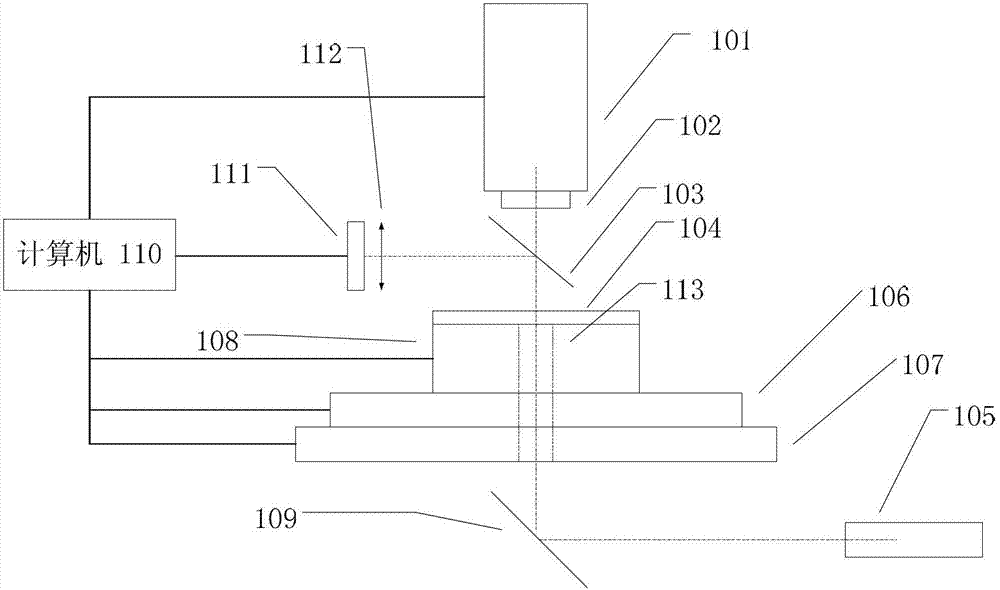

[0031] figure 1 It is a schematic diagram of the device for adjusting the inclination of the measured part in the planar sub-aperture splicing measurement of the present invention, including a Fizeau phase-shifting interferometer 101, a standard mirror 102, a half-transparent mirror 103, a measured mirror 104, and a laser autocollimator 105 , a two-dimensional translation stage 106 , a tilt adjustment device 107 , a turntable 108 , a flat mirror 109 , a computer 110 , a detector 111 , and a focusing lens 112 . Wherein the center of the turntable 108, the two-dimensional translation stage 106, and the inclination adjustment device 107 has a light hole 113; the optical axis of the half-transparent mirror 103 and the Fizeau phase-shifting interferometer 101 forms an angle of 45 degrees, and the plane reflector 109 and The rotation axis of the tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com