Winding inductor of open magnetic circuit

A wire-wound inductor and open magnetic circuit technology, applied in the field of inductance, can solve the problems of increasing the risk of inductive short circuit, large short circuit risk, and reducing the insulation performance between coils, so as to prevent the damage of thermal radiation to the coil and improve the resistance to cold and heat Impact ability, the effect of improving the ability to resist high temperature in the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described below in combination with specific embodiments and with reference to the accompanying drawings.

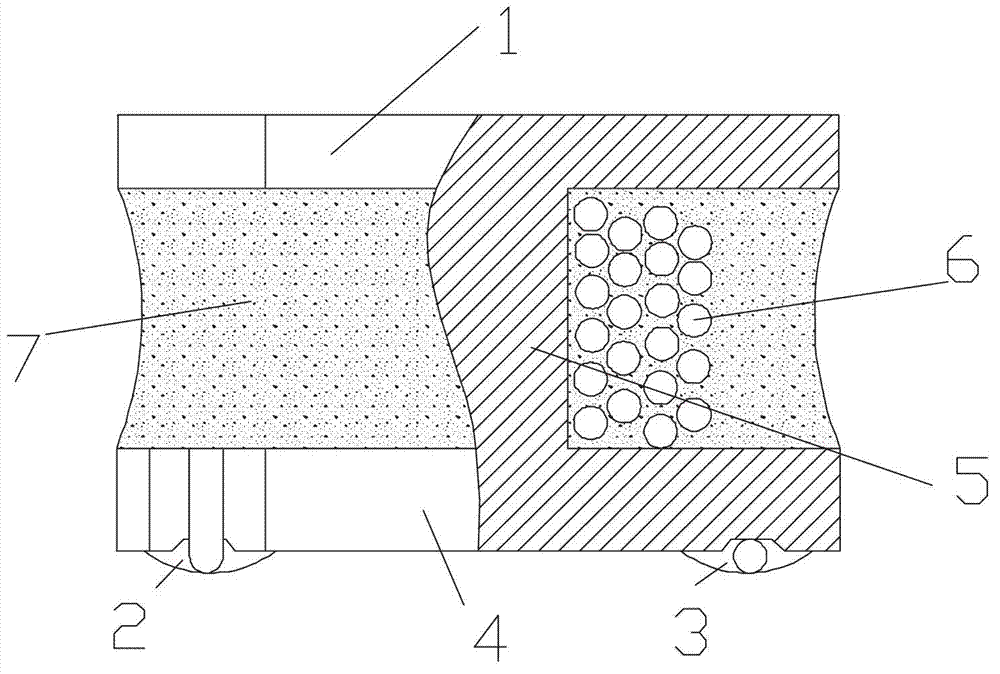

[0021] An open magnetic circuit wound inductance as shown in the accompanying drawings, including an upper blade 1, a lower blade 4 with two terminal electrodes 2, 3 formed on the surface, and a core post 5 with an outer diameter of 6 mm and a height of 2.5 mm. An I-shaped ferrite core, and a coil 6 wound on the core post 5 .

[0022] The coil 6 of this specific embodiment is a coil wound with 11 coils on an I-shaped ferrite core with an outer diameter of 6 mm and a height of 2.5 mm by using an enameled wire with a diameter of φ0.22 mm.

[0023] The two terminal electrodes 2, 3 are respectively connected to the two ends of the coil 6, the edge of the upper blade 1 and the lower blade 4 of the I-shaped ferrite core has no support, and the outer layer of the coil 6 and the I-shaped iron A non-magnetic resin 7 with low thermal conductiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| inductance | aaaaa | aaaaa |

| inductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com