Permanent magnet auxiliary synchronized reluctance motor rotor and manufacturing method thereof and motor

A technology for assisting synchronous and reluctance motors, applied to synchronous motors with stationary armatures and rotating magnets, magnetic circuit rotating parts, manufacturing stator/rotor bodies, etc., can solve problems that affect motor performance and are difficult to process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

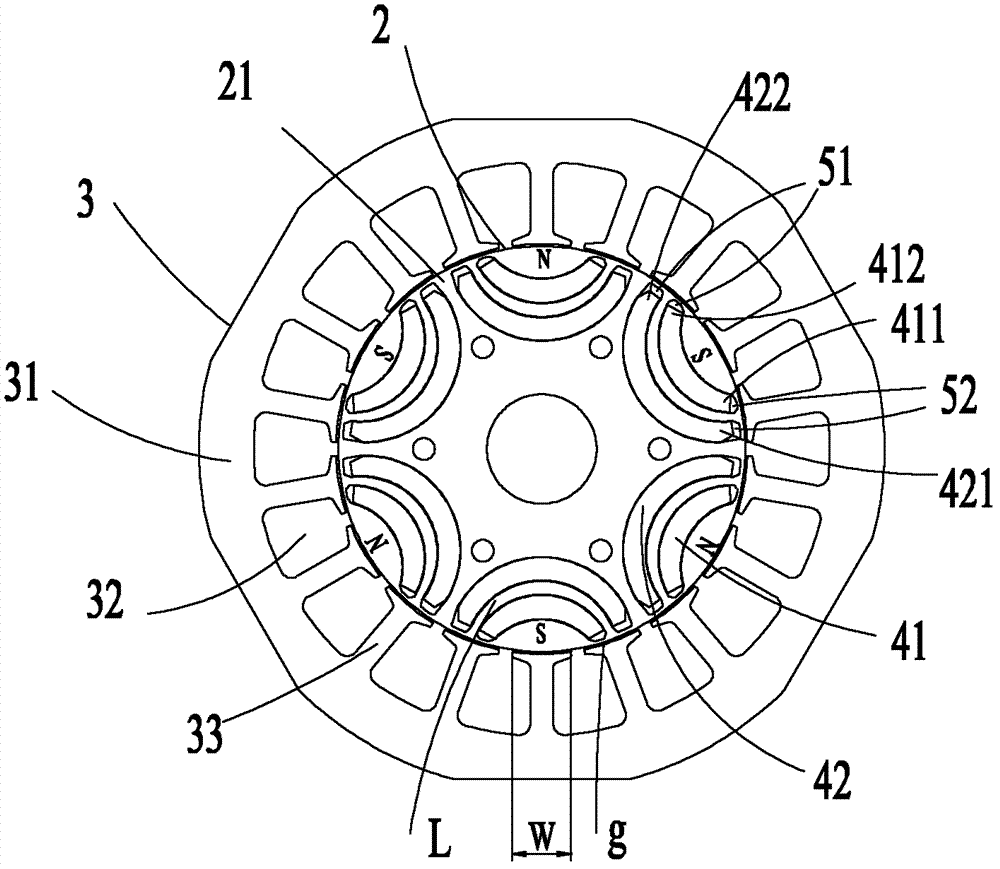

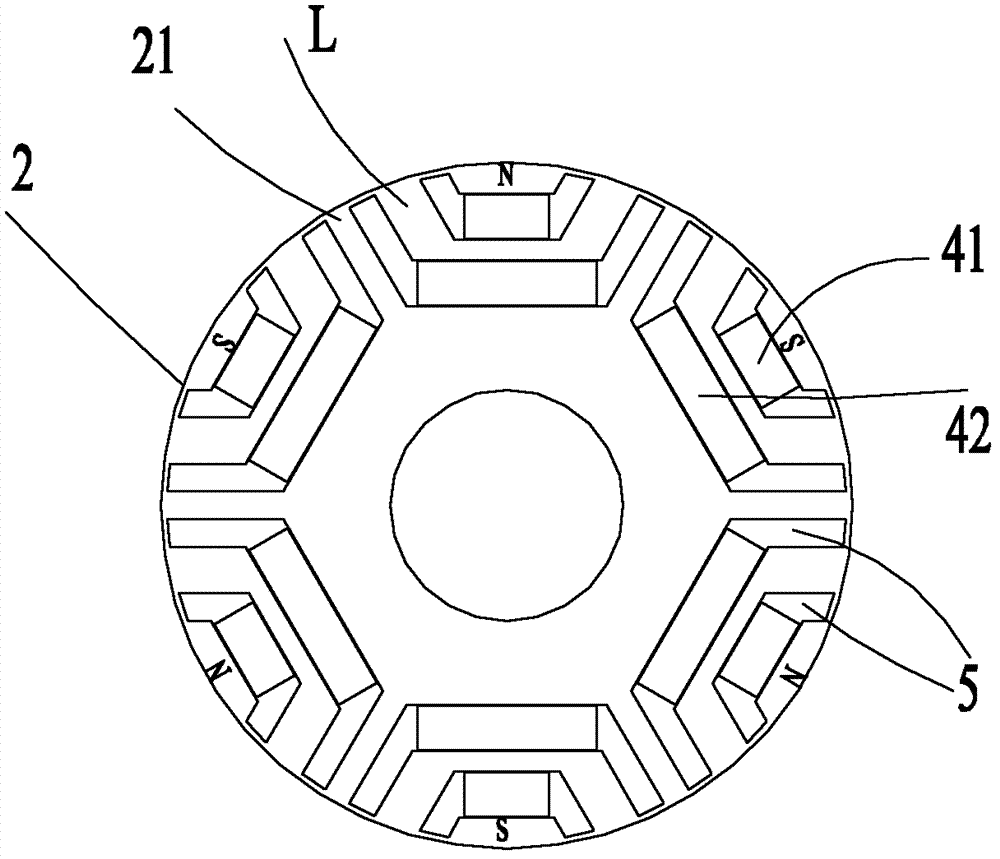

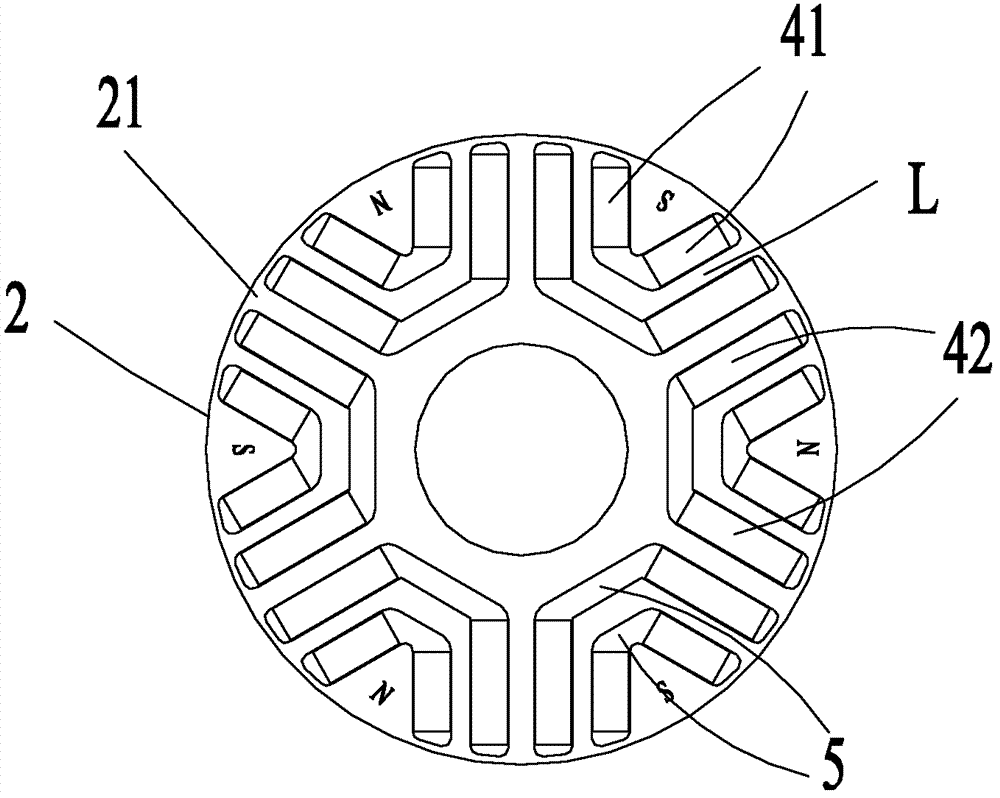

[0026] figure 1 shows a sectional view of the permanent magnet assisted synchronous reluctance motor of the present invention, which includes a rotor 2 and a stator 3 located outside the rotor 2 and having a certain gap g with the rotor 2 . The stator 3 includes a stator core 31 provided with a plurality of slots 32 and a plurality of teeth 33 in the circumferential direction, and a winding (not shown) placed in the slots 32 . Wherein, the rotor 2 includes a rotor core 21 provided with multiple sets of magnetic pole units. All the magnetic pole units are arranged in the form of alternating N poles and S poles in the circumferential direction of the rotor. Each set of magnetic pole units includes two layers of permanent magnets for built-in permanent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com