Anti-fog polyester film and preparation method thereof

A polyester film, anti-fog technology, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of thick thickness and poor thermal stability, and achieve thin thickness, good thermal stability, The effect of high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

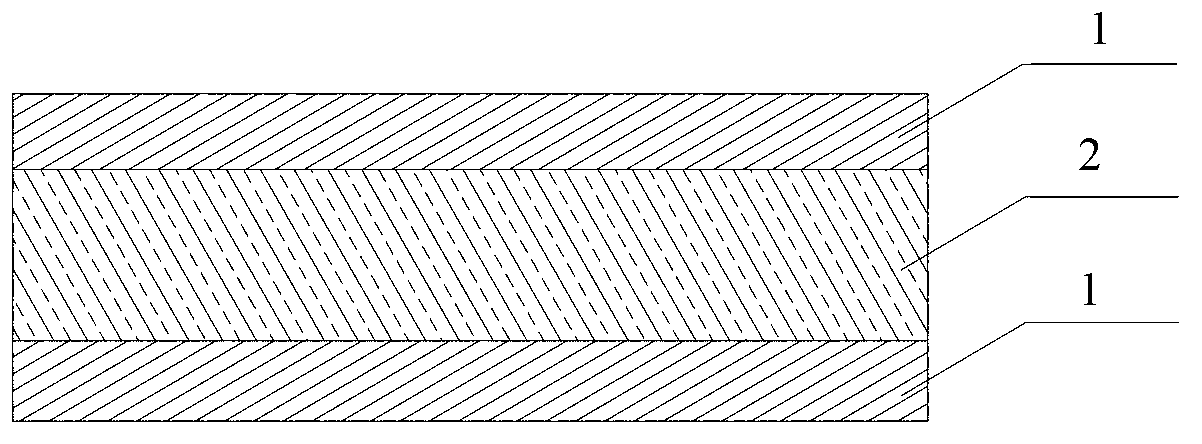

Image

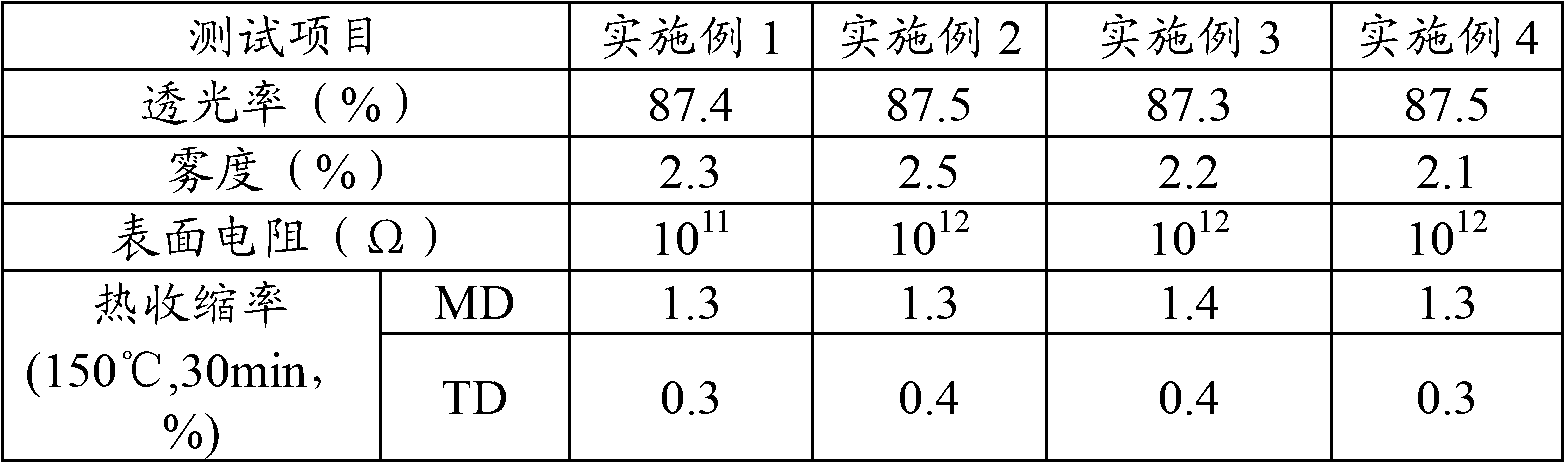

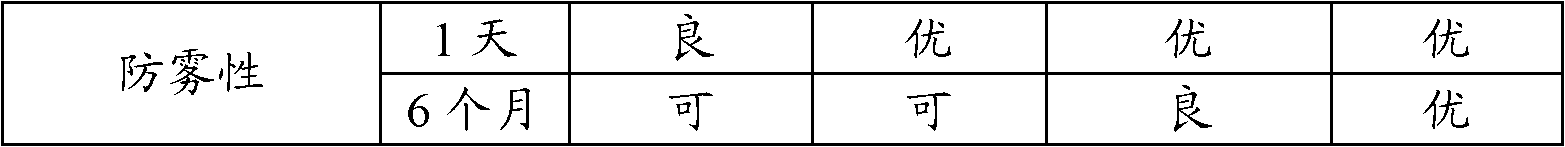

Examples

preparation example Construction

[0041] The preparation method of anti-fog polyester film provided by the invention comprises the steps:

[0042] (1) Mix the raw materials of the functional layer, pre-crystallize at 120-140°C, the pre-crystallization time is 10-20min; dry at 175-180°C, the drying time is 4-6h;

[0043] (2) Mix the raw materials of the polyester base material, pre-crystallize at 120-140°C, the pre-crystallization time is 10-20min; dry at 175-180°C, the drying time is 4-6h.

[0044](3) Melt and extrude the functional layer raw material obtained in step (1) through a twin-screw extruder. The temperature of each zone is set as follows: 265°C for the first zone, 270°C for the second zone, 275°C for the third zone, and 275°C for the fourth zone. The fifth zone is 275°C, the temperature of the machine head: 270°C; at the same time, the polyester substrate raw material obtained in step (2) is melted and extruded through a single-screw extruder, and the temperature of each zone is set as follows: the ...

Embodiment 1

[0058] 100 parts of polyester chip raw materials, kneading in a mixer, adding 1.5 parts of nonylphenol polyoxyethylene ether, 0.2 parts of polyvinyl alcohol, the mixture is used as the raw material of the anti-fog functional layer; the polyester base material is 20% pure resin Chips and 80% recycled polyester chips. A film with a thickness of 75 micrometers was prepared, wherein the thickness of the anti-fog functional layer was 10 micrometers, and the thickness of the polyester substrate was 55 micrometers.

Embodiment 2

[0060] 100 parts of raw materials for polyester chips, kneading in a mixer, adding 1.5 parts of nonylphenol polyoxyethylene ether and 0.3 parts of polyvinyl alcohol, the mixture is used as the raw material for the anti-fog functional layer; the polyester substrate is 20% pure resin Chips and 80% recycled polyester chips. A film with a thickness of 75 microns was prepared, wherein the anti-fogging functional layer was 10 microns, and the polyester substrate was 55 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com