Loading, unloading and detection workbench system for PVC (polyvinyl chloride) floor

A detection workbench and detection system technology, applied in the direction of conveyor control devices, conveyor objects, transportation and packaging, etc., can solve the problems of reducing work efficiency, increasing inspection time, increasing labor force, etc., to improve work efficiency and equipment structure Simple, labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

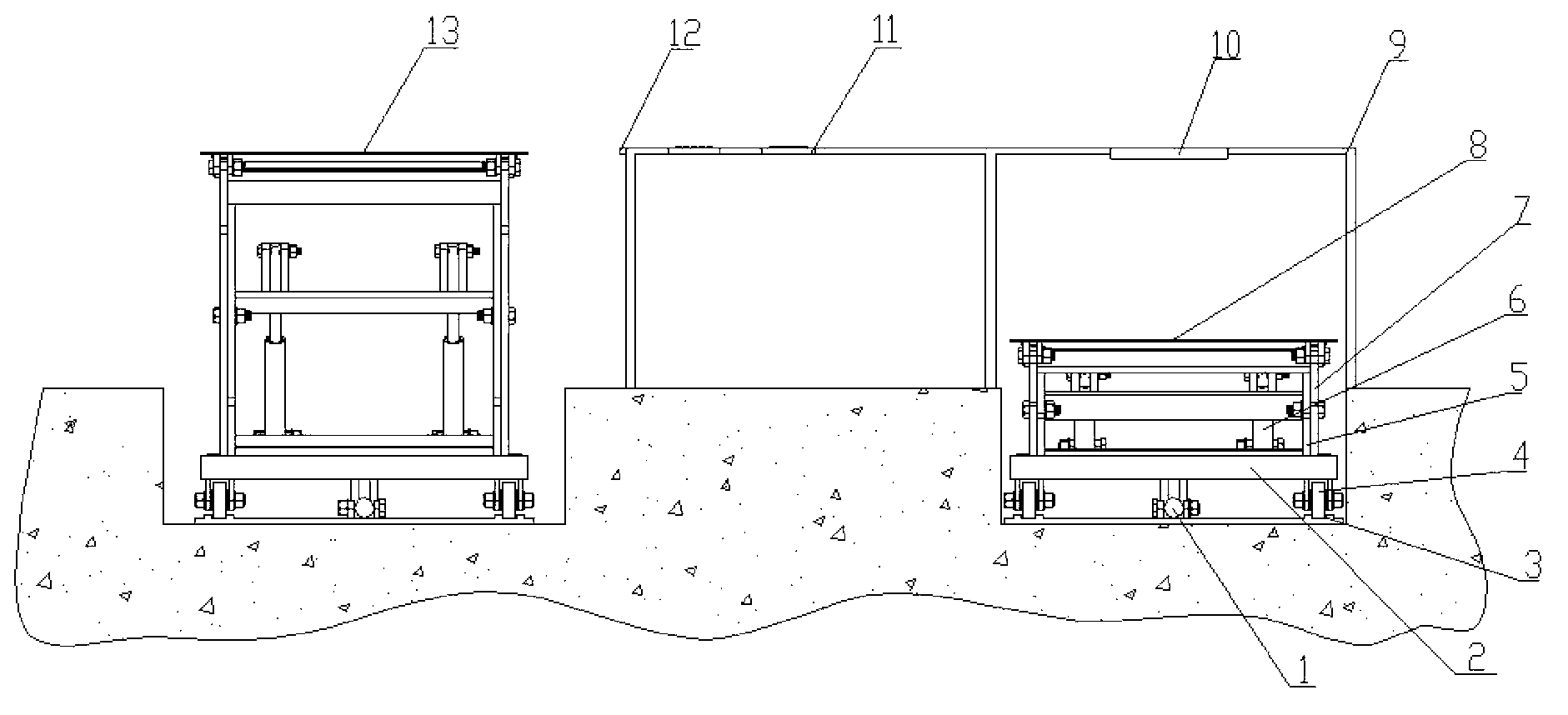

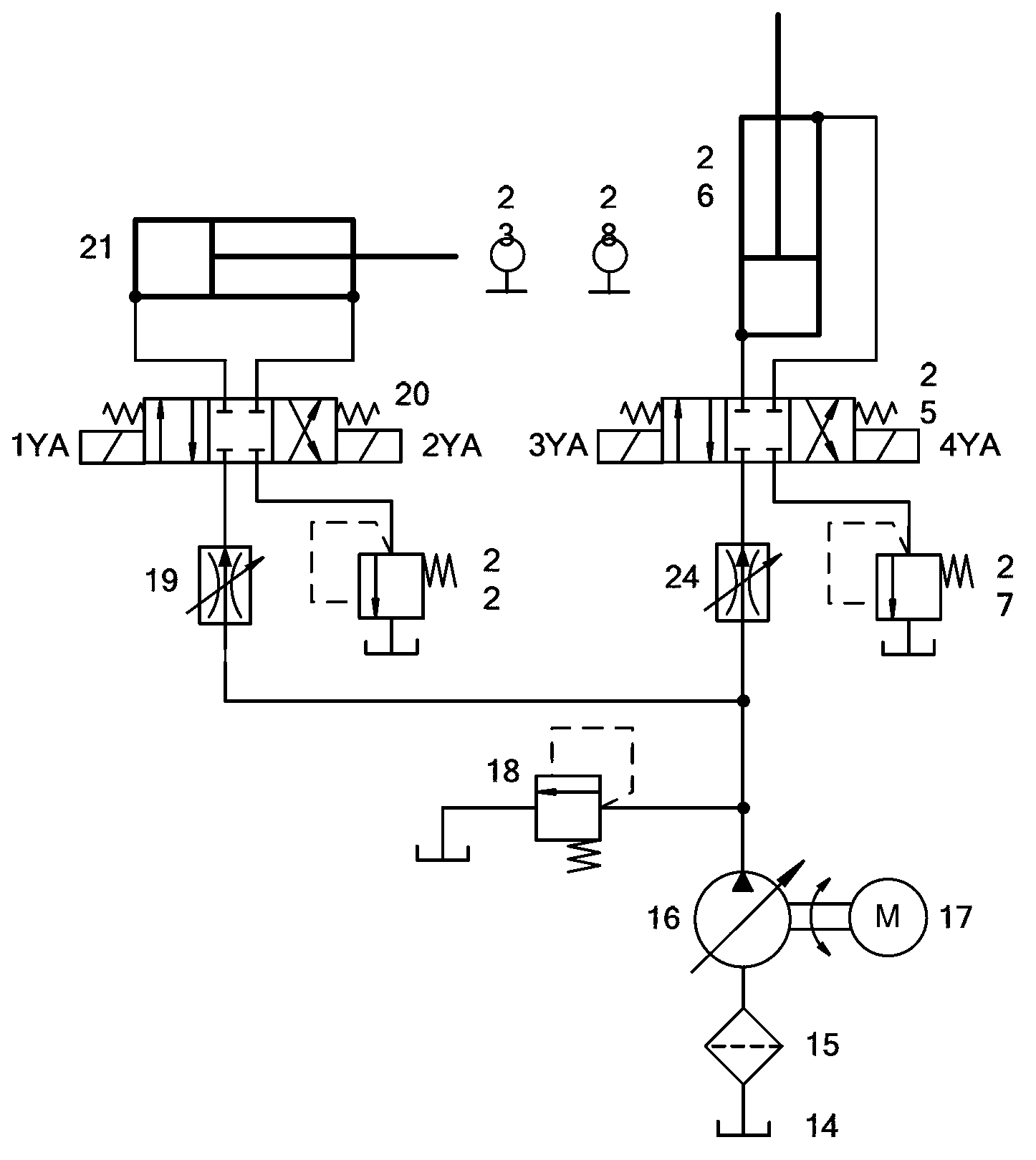

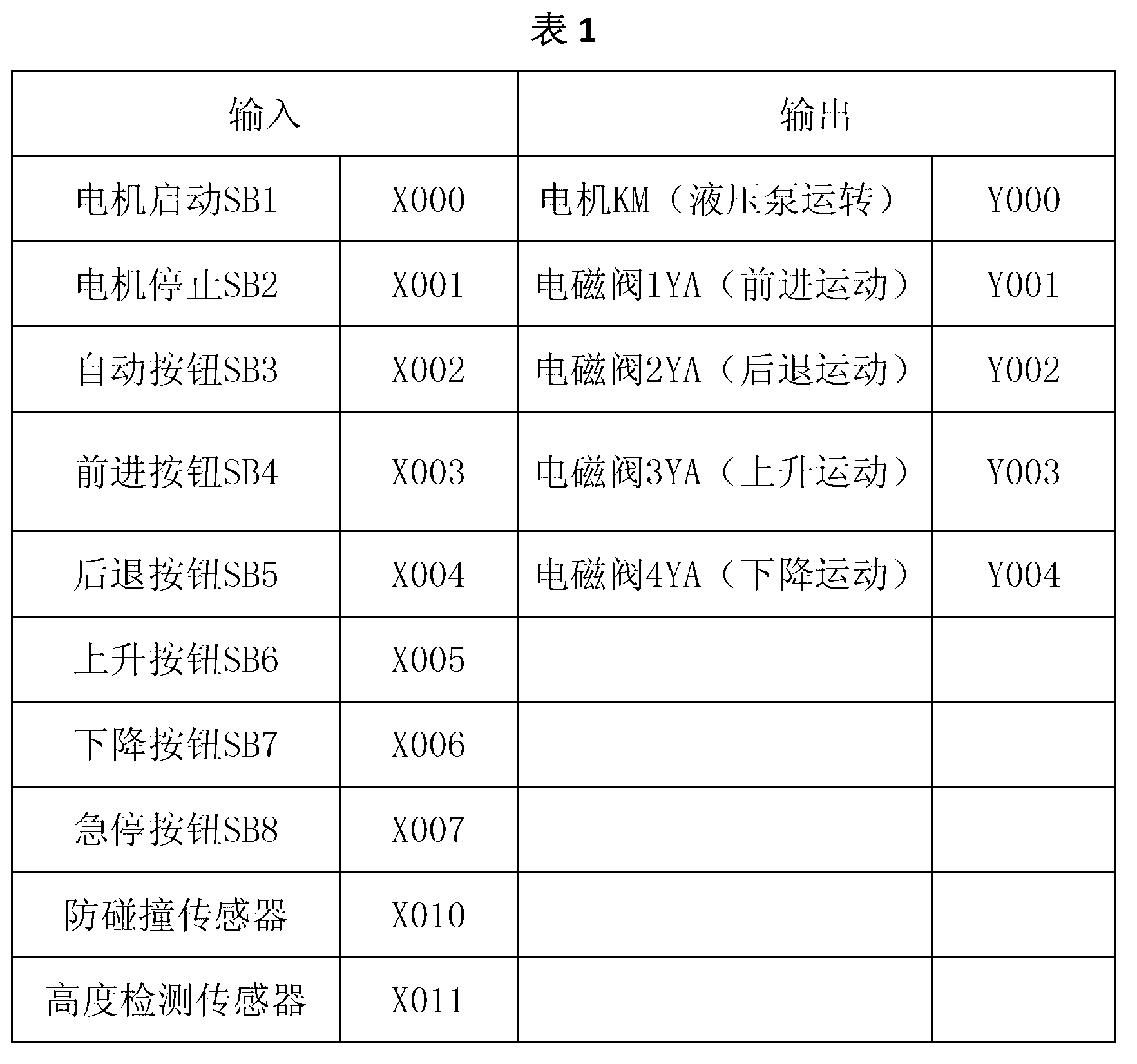

[0020] see figure 1 , the loading scissor lift equipment in the present invention can move up and down, also can move back and forth, stack 4-5 piles of PVC floors on the initial state loading scissor lift equipment, and the loading scissor lift equipment is placed below the horizontal plane, The lowermost roller rotates on the guide rail under the push of the hydraulic cylinder, thereby driving the entire loading scissor lifting equipment to move forward and backward. The workbench is placed horizontally, and the materials can be piled up to about the height of the workbench. First, unload the PVC floor closest to the workbench to the workbench. The thickness of the unloaded PVC floor reaches half of the total thickness, and then the button controls the hydraulic cylinder 1 to make the loading shear The lifting equipment moves a certain distance towards the workbench; then unload the second stack of PVC floors, and the thickness of the PVC floors sent to the workbench is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com