Methods for removing calcium and magnesium and co-producing water and salt by low-cost process during sea water desalination

A technology for removing calcium and magnesium, applied in chemical instruments and methods, seawater treatment, water/sewage multi-stage treatment, etc., can solve the problems of unbearable cost pressure, large refining cost and large water volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

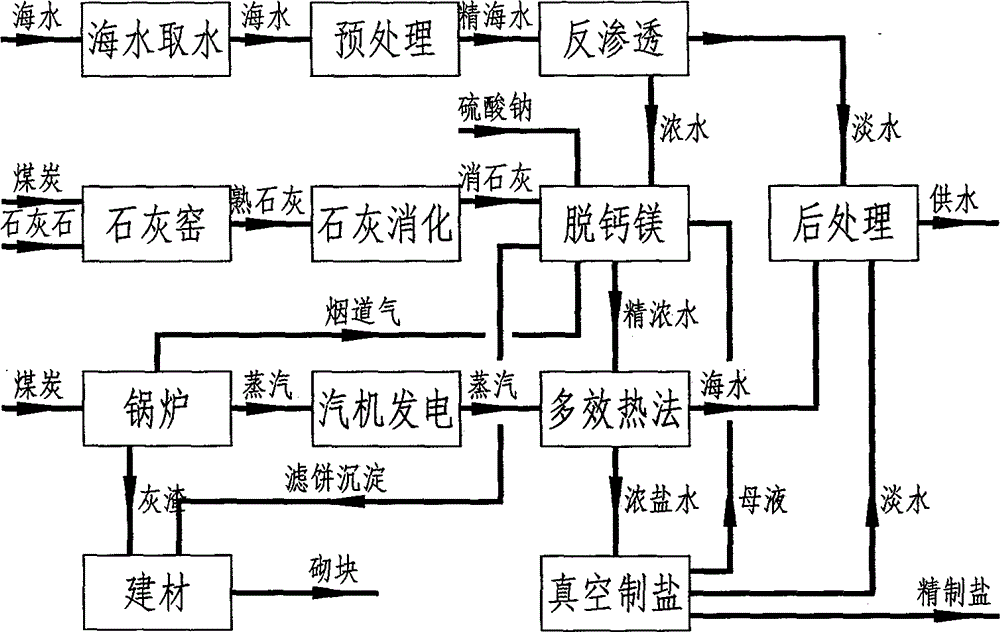

[0034] Brief description of the process:

[0035] 1. Concentrated water process: Concentrated seawater or seawater from the previous process is pressurized into the system through a pump. First, the mother liquor containing sodium sulfate and Glauber’s salt are added to the Glauber’s salt preparation tank at an appropriate temperature and under stirring conditions. Or Yuanming powder, so that the concentration of sulfate ions in the concentrated water meets the requirements for removing calcium and magnesium ions.

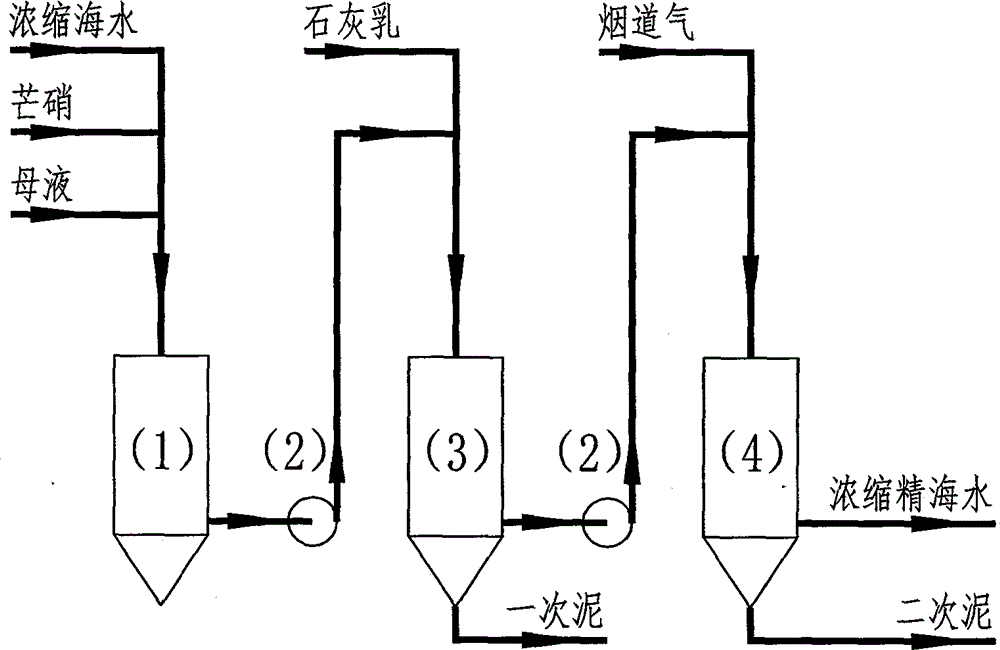

[0036] Then, in the causticizing reaction tank for magnesium removal, milk of lime is added to the concentrated seawater that has been added with sodium sulfate, calcium hydroxide reacts with magnesium ions to form magnesium hydroxide precipitate, calcium hydroxide reacts with sodium sulfate to generate calcium sulfate and NaOH was provided to separate the precipitate by adding flocculant and static sedimentation.

[0037] The alkaline concentrated water from whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com