Warm mix asphalt and preparation method thereof

A warm-mix asphalt and mixture technology, applied in the direction of climate change adaptation, etc., can solve problems such as asphalt aging, high energy consumption, and heavy environmental pollution, and achieve the effects of reducing aging, simplifying production procedures, and extending transportation distances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

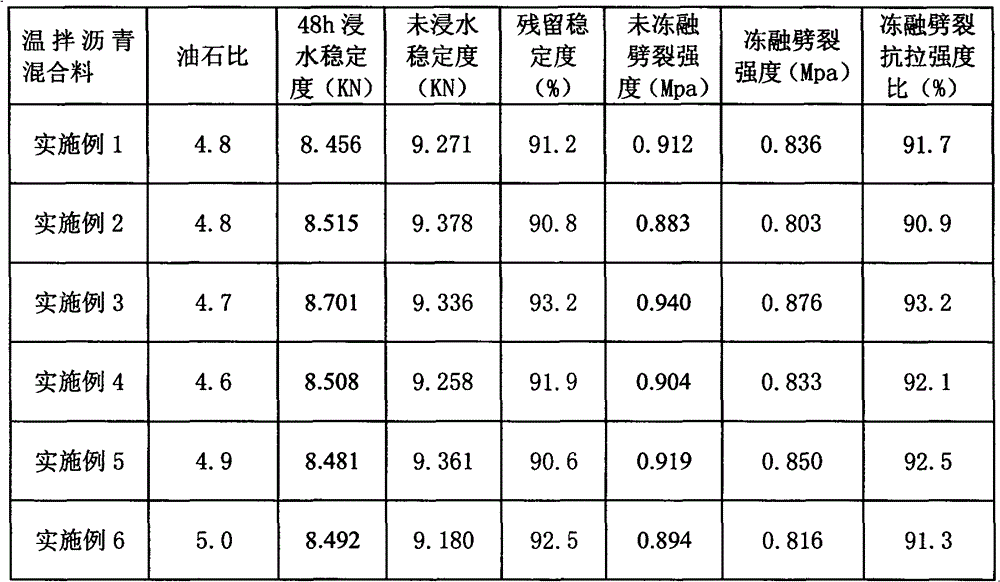

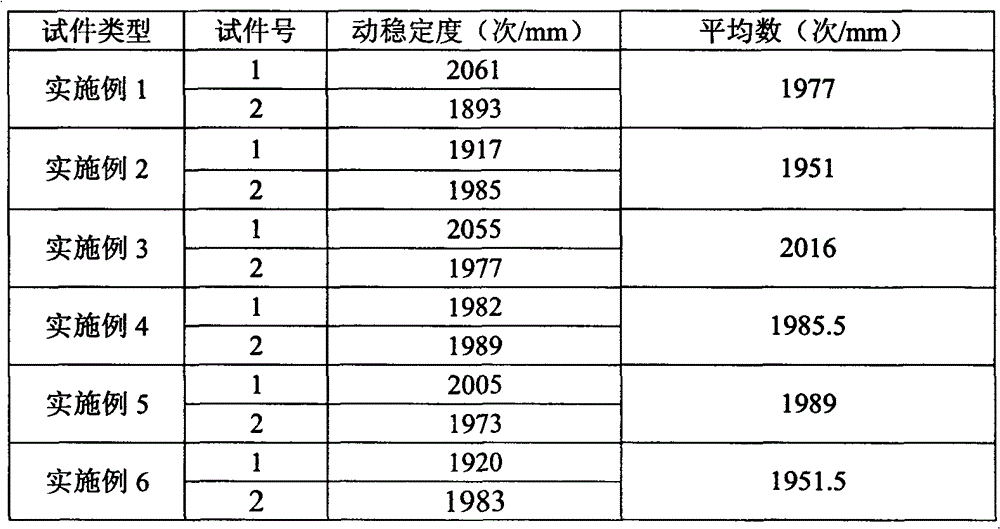

Embodiment 1

[0021] Take 10054g of aggregate, heat it to 150°C and dry it, add it to the mixing pot, keep the temperature in the mixing pot at 140°C, take 498g of 70# asphalt and heat it to 154°C, add it to the mixing pot, sprinkle 32.6g of warm mix agent on For the surface of asphalt, stir in the mixing pot for 135s; add 311g of ore powder into the mixing pot, and stir for 85s, wherein 25% of its weight in the ore powder is slaked lime; put the mixed material out of the pot at 138°C, Molded at 130°C, the warm mix asphalt mixture can be obtained.

Embodiment 2

[0023] Take 10158g of aggregate, heat it to 145°C and dry it, add it to the mixing pot, keep the temperature in the mixing pot at 145°C, take 381g of 70# asphalt and heat it to 160°C, add it to the mixing pot, sprinkle 32.8g of warm mix agent on the For the surface of asphalt, stir in the mixing pot for 120s; add 423g of mineral powder into the mixing pot, and stir for 95s; take the mixed mixture out of the pot at 140°C, and shape it at 135°C to obtain warm asphalt mixture .

Embodiment 3

[0025] Take 10189g of aggregate, heat it to 155°C and dry it, add it to the mixing pot, keep the temperature in the mixing pot at 140°C, take 435g of 70# asphalt and heat it to 158°C, add it to the mixing pot, sprinkle 33.1g of warm mix agent on For the surface of asphalt, mix in the mixing pot for 135s; add 424g of mineral powder into the mixing pot, and stir for 100s; take the mixed material out of the pot at 135°C, and shape it at 130°C to obtain warm asphalt mixture .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com