Production method of ceramsite lightweight concrete batten by using non-autoclaved technology

A lightweight concrete and autoclave-free technology, applied in the field of new environmental protection building materials, can solve the problems of large energy consumption, high equipment investment, and long maintenance time, and achieve environmental protection, resource conservation, good economic and social benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

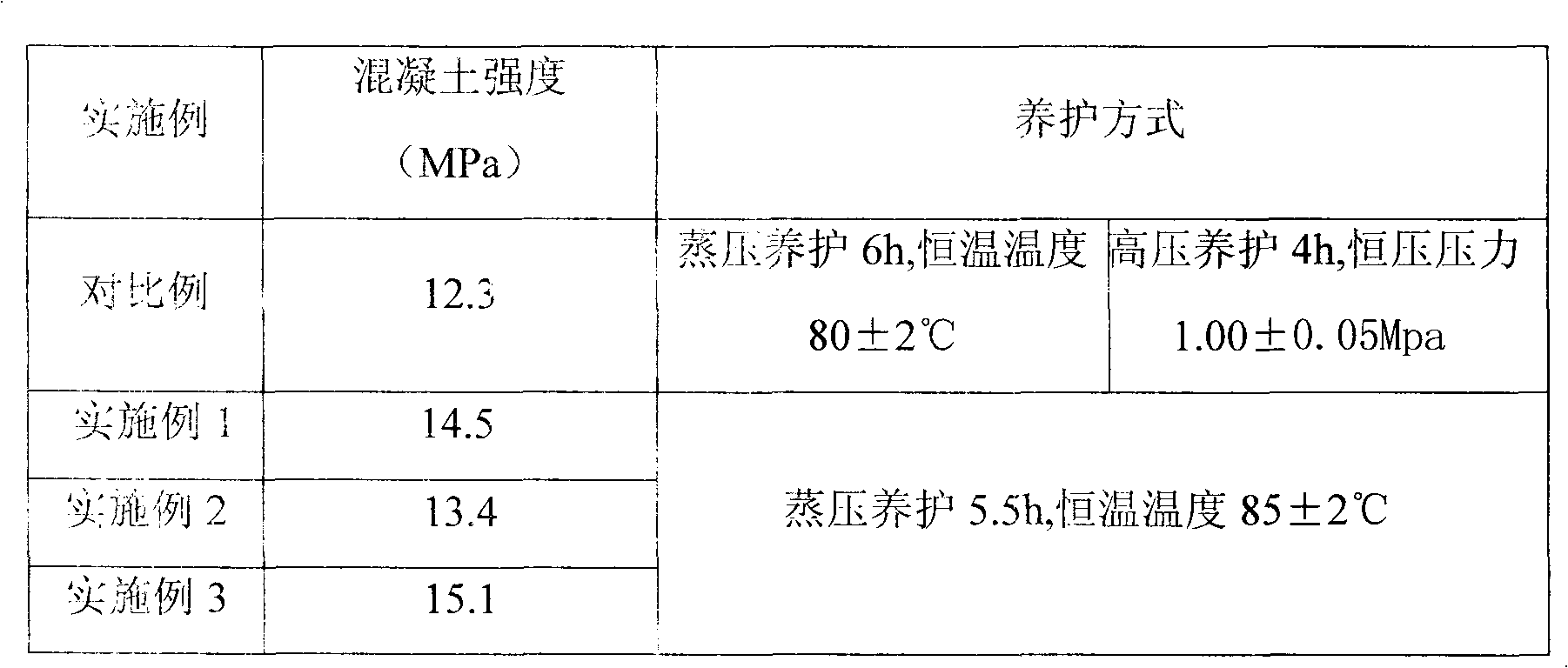

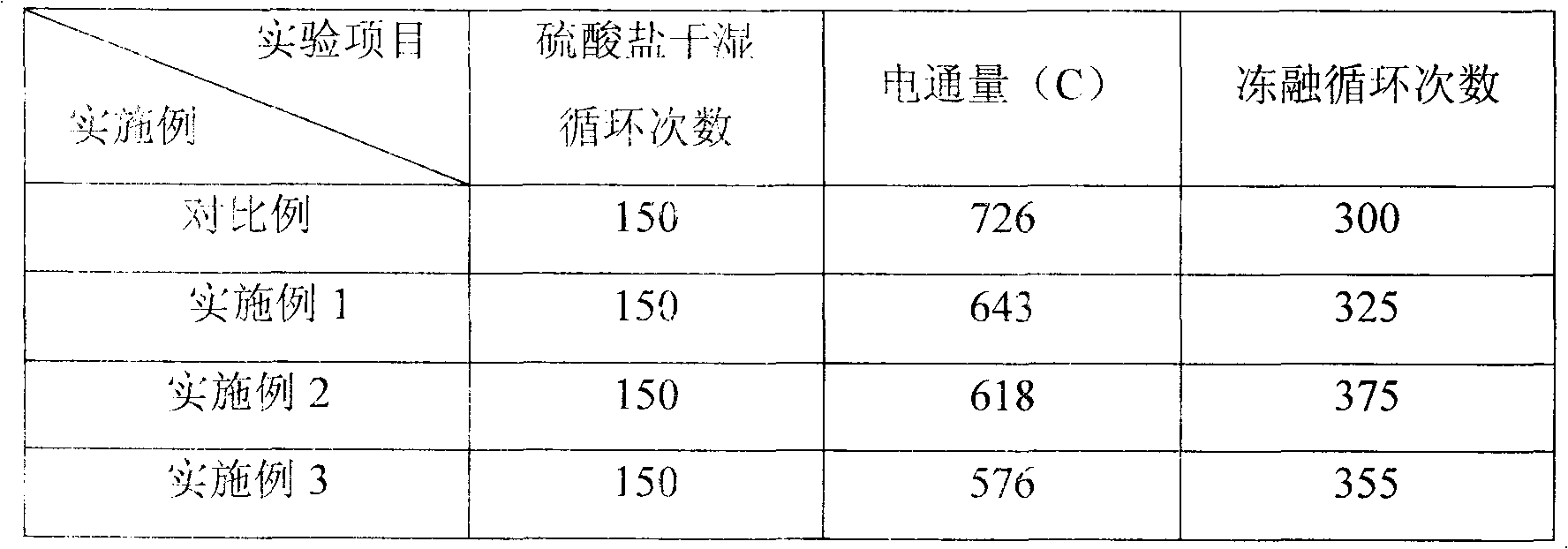

Embodiment 1

[0026] Embodiment 1: produce a kind of method that adopts autoclave-free technique to produce ceramsite lightweight concrete slab (wallboard), form by ceramsite concrete pouring, described ceramsite concrete comprises following components: cementitious material, fine Aggregate, coarse aggregate, water reducing agent, foaming agent and water, among which, the concrete density is 1400kg / m 3 , the amount of cementitious material 350kg / m 3 , is 90% cement + 10% high activity synergist, the amount of natural river sand is 600kg / m 3 , the amount of artificial lightweight ceramsite is 600L / m 3 , the water-binder ratio is 0.35, and the amount of foam after the foaming agent is foamed at a certain rate is 200L / m 3 , The water reducer dosage (solid dosage) is 0.1% of the weight of the gelling material.

Embodiment 2

[0027] Embodiment 2: produce a kind of method that adopts autoclave-free technique to produce ceramsite lightweight concrete slab (wall board), form by ceramsite concrete pouring, described ceramsite concrete comprises following components: cementitious material, fine Aggregate, coarse aggregate, water reducer, foaming agent and water; among them, the concrete density is 1250kg / m 3 , the amount of cementitious material is 380kg / m 3 , is 55% cement + 35% mineral powder + 10% high activity synergist, the amount of natural river sand is 550kg / m 3 , the amount of artificial lightweight ceramsite is 650L / m 3 , the water-to-binder ratio is 0.37, and the amount of foam used by the foaming agent after foaming at a certain rate is 220L / m 3 , The water reducer dosage (solid dosage) is 0.15% of the weight of the gelling material.

Embodiment 3

[0028] Embodiment 3: produce a kind of method that adopts autoclave-free technology to produce ceramsite lightweight concrete slab (wall board), form by ceramsite concrete pouring, described ceramsite concrete comprises following components: cementitious material, fine Aggregate, coarse aggregate, water reducing agent, foaming agent and water; among them, the concrete density is 1000kg / m 3 , the amount of cementitious material 400kg / m 3 , 50% cement + 30% fly ash + 20% high activity synergist, the amount of natural river sand is 500kg / m 3 , the amount of artificial lightweight ceramsite is 700L / m 3 , the water-to-binder ratio is 0.40, and the amount of foam after the foaming agent is foamed at a certain rate is 250L / m 3 , The water reducer dosage (solid dosage) is 0.2% of the weight of the gelling material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com