High-performance corrosion-resisting concrete pile and preparation method thereof

A corrosion-resistant concrete, high-performance technology, applied in the direction of manufacturing tools, reinforced molding, ceramic molding machines, etc., can solve the problems of poor durability of concrete structures, cracking of concrete structure performance, and reduced durability, so as to achieve significant social benefits and products Effect of quality assurance and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

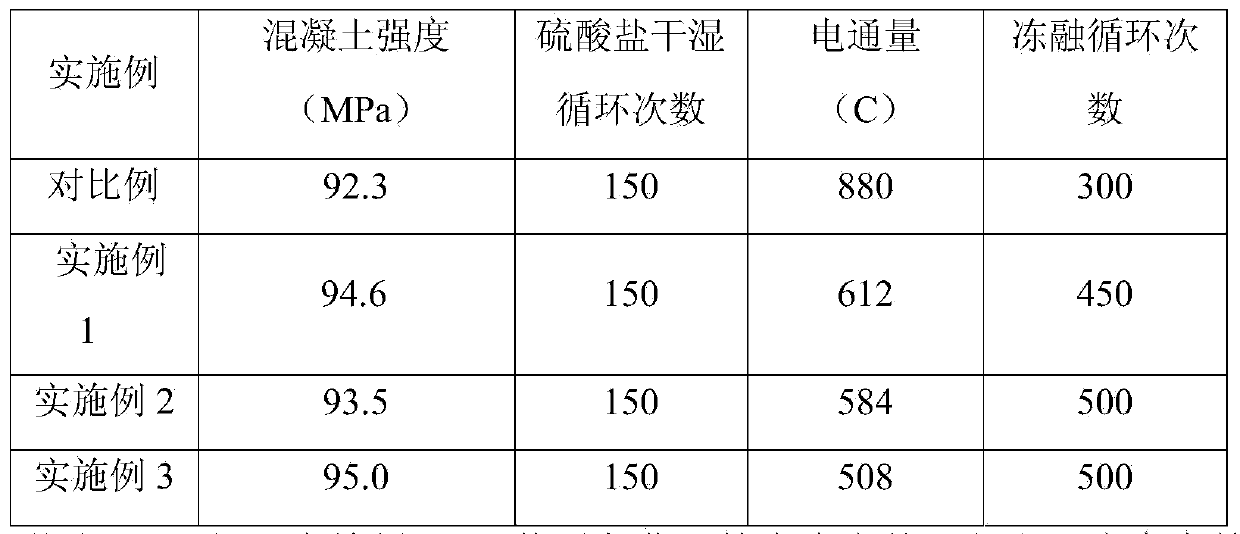

Examples

Embodiment 1

[0019] A high-performance corrosion-resistant concrete pile whose concrete contains 420kg / m 3 Cementitious materials, natural sand, gravel, polycarboxylate superplasticizer and water, the water-cement ratio is 0.32. Among them, the fineness modulus of natural sand is 3.0, and the sand rate is 36%; the particle size of gravel is 5-25mm, and the crushing value is 5%; and the water reducer (solid content) is 1.0% of the total cementitious material. %; Among them, the cementitious material is composed of 54% cement, 35% fly ash (mineral admixture) and 10% high activity synergist. And the percentage by weight of each composition of this high-activity synergist is respectively: 10% active silicon, 70% natural ground gypsum, 14% calcium oxide, 1% N-acyl sodium lauryl sarcosinate and 5% % of inorganic silicates. The concrete density ratio of the above formula is about 2500kg / m 3 .

Embodiment 2

[0021] A high-performance corrosion-resistant concrete pile whose concrete contains 450kg / m 3 For cementitious materials, natural sand, gravel, naphthalene-based high-efficiency water reducer and water, the water-cement ratio is 0.30. Among them, the fineness modulus of natural sand is 2.8, and the sand rate is 35%; the particle size of gravel is 5-25mm, and the crushing value is 5%; and the amount of water reducing agent used is 3.5% of the total cementitious material; The cementitious material is composed of 45% cement, 40% mineral powder (mineral admixture) and 15% highly active synergist. The composition formula of this high activity synergist is 50% ultrafine fly ash as active silicon, 20% desulfurized gypsum sulfate, 15% calcium oxide, 1% potassium N lauroyl glycinate and 4% inorganic Mixture of silicate and sodium carbonate. The concrete density ratio of the above formula is about 2450kg / m 3 .

Embodiment 3

[0023] A high-performance corrosion-resistant concrete pile whose concrete contains 430kg / m 3 For cementitious materials, artificial sand, gravel, polyhydroxy acid superplasticizer and water, the water-cement ratio is 0.28. Among them, the fineness modulus of artificial sand is 3.0, and the sand rate is 37%; the particle size of gravel is 5-25mm, and the crushing value is 5%; and the amount of water reducing agent used is 4% of the total cementitious material; The cementitious material is composed of 85% cement and 15% highly active synergist. And the composition formula of this high-activity synergist is 1% (weight) of silica fume, 10% of desulfurized gypsum, 60% of calcium oxide, 0.5% of N-lauroyl sodium glutamate and 1.5% of silicate and sodium carbonate mixture. The concrete density ratio of the above formula is about 2550kg / m 3 .

[0024] Examples 1-3 Prepare concrete piles by the following method: the specific production process is as follows: (1) first put sand and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| sand rate | aaaaa | aaaaa |

| sand rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com