Shot-slag separation device

A slag separation and separation plate technology, which is applied in solid separation, used abrasive treatment device, and air flow to separate solids from solids, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

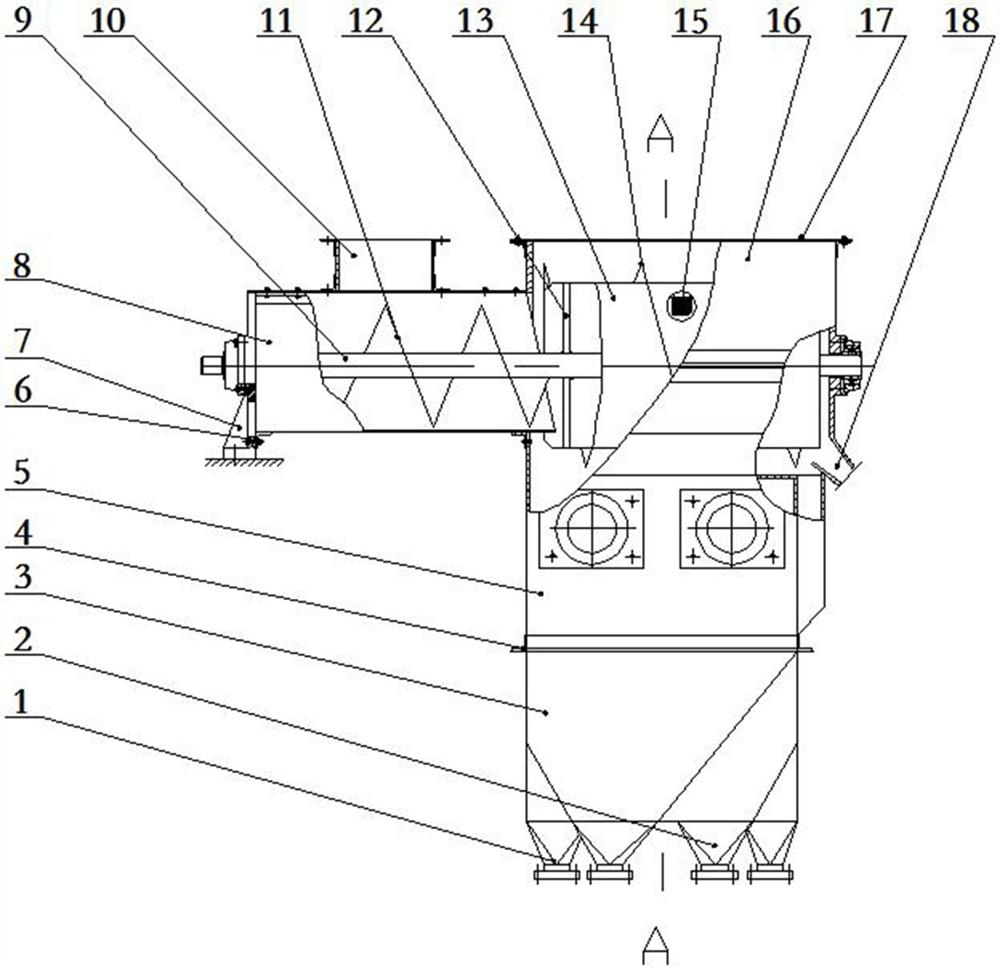

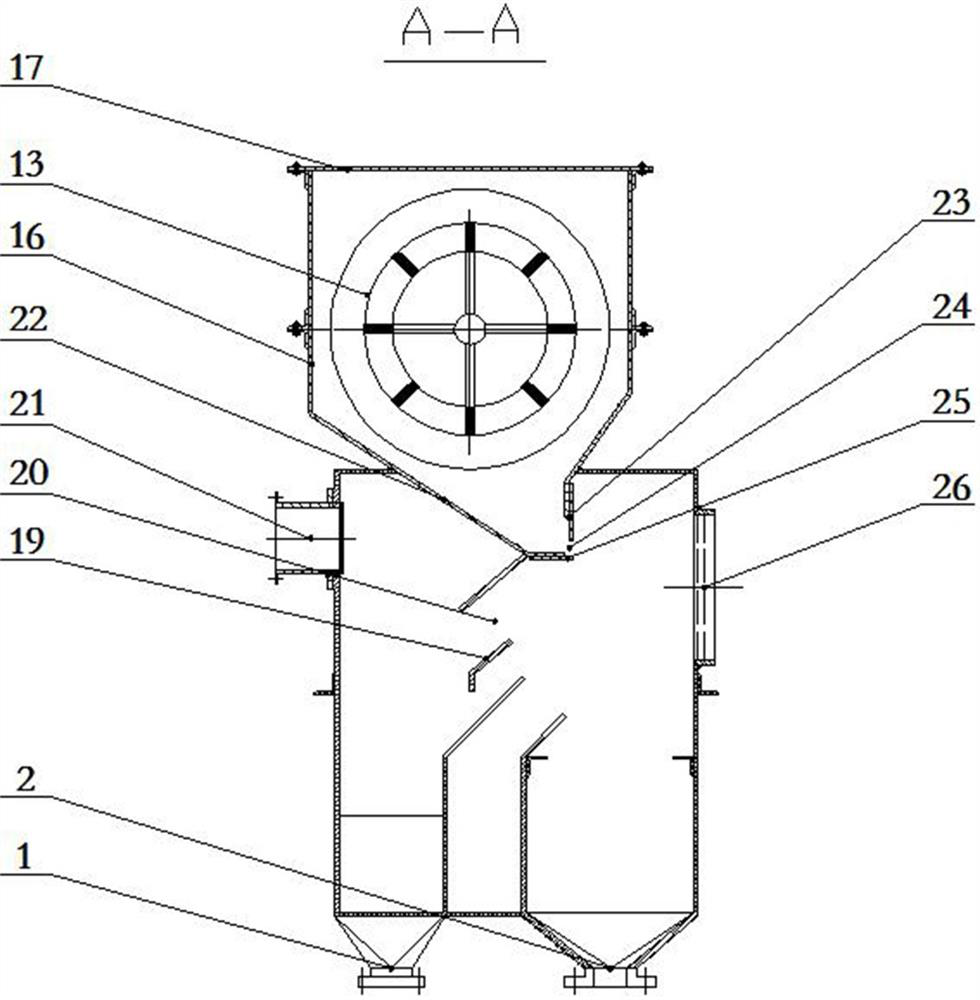

[0038] Attached from the manual figure 1 and figure 2 It can be seen from the pellet and slag separation device shown in that the separation link includes two parts, one is screening, and the other is winnowing. Compared with multiple links in the prior art, there are only two links, of which the first One link, that is, screening, is screening in motion. Specifically, the screw conveyor screens during the conveying process. As the material moves forward, part of the material is screened, and the remaining material is less and less. Avoid static For the problem of mutual superimposition of the lower screening materials, the screening effect is relatively good, and the feeding is continuous, which does not affect the screening efficiency. The part that cannot be screened is directly discharged from the end of the screening part. In the conventional scheme, the wind selection mainly adopts the air extraction method, because there are many air leakage points in the pellet and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com