Substrate material coated with polymer needled tufts of natural-Opuntia-microdasys-plant-like structure

A base material and polymer technology, applied in the field of bionic water-collecting polymer acupuncture clusters, can solve the problems of low water collection efficiency, inability to meet water needs, and high water collection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

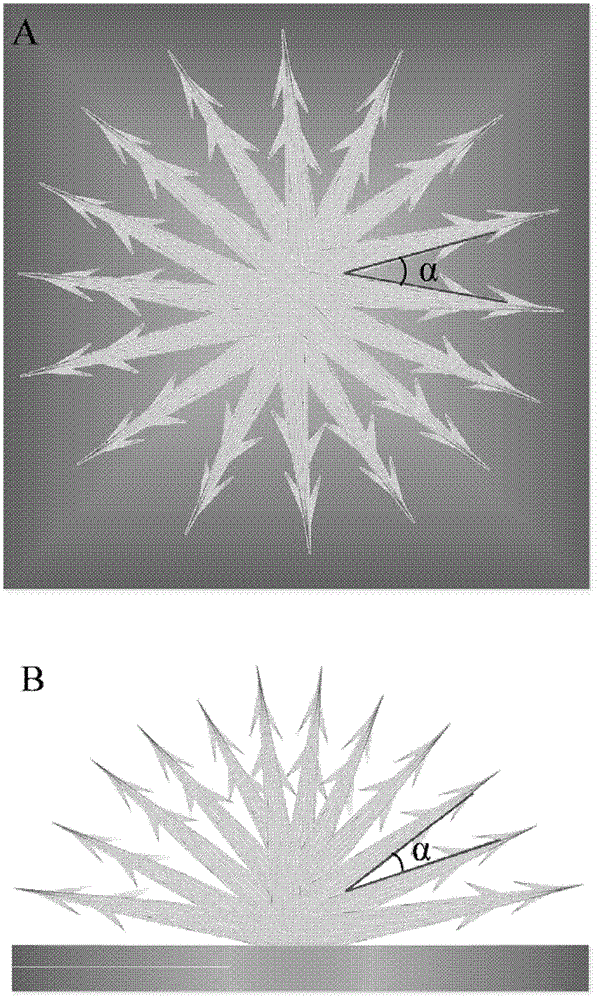

[0082] I. Preparation of PMMA needle-punched clusters imitating the natural plant structure

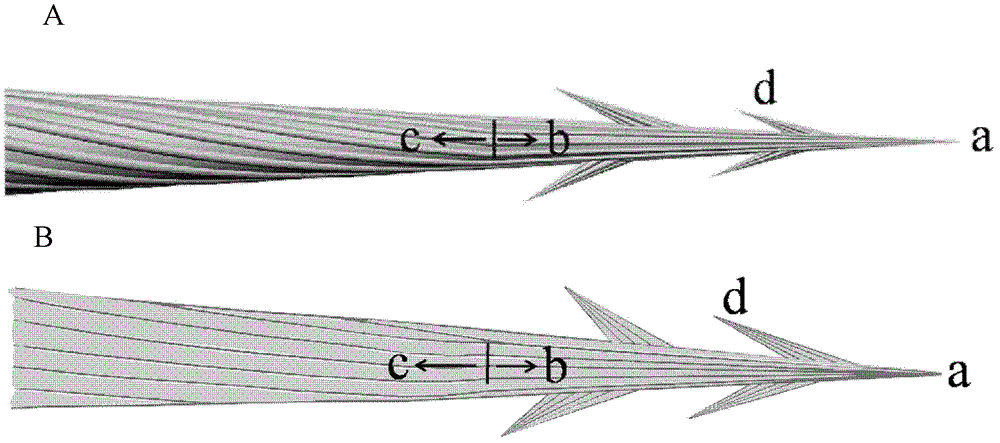

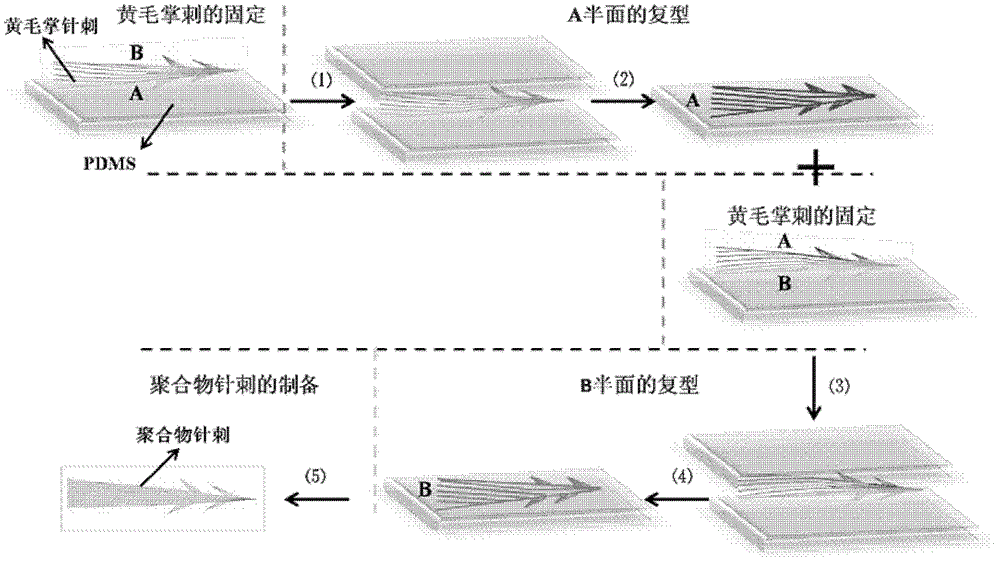

[0083] I imitate the preparation of the single PMMA main acupuncture of natural palm plant structure, please refer to figure 2

[0084] 1) Fixation in a semi-submerged state of needle-punched natural palmetto plants

[0085] Mix the PDMS prepolymer and the curing agent two-component glue used together to obtain a mixed glue, wherein: the weight ratio of the PDMS prepolymer glue to the curing agent glue is 10:1; for the mixed glue First use ultrasonic wave for 5 minutes to remove the large air bubbles in the mixed glue, and then vacuumize the mixed glue to a vacuum degree of 10 -4 Pa, keep 10min to remove the small air bubbles in the mixed glue; get a fresh natural palm plant acupuncture (structure such as figure 1 Shown in A) is placed on the surface of the mixed glue solution after defoaming; the mixed glue solution after defoaming is cured in an oven at a temperature of 40° C. t...

Embodiment 2

[0103] I. Preparation of PS needle-punched clusters imitating the natural plant structure

[0104] I imitate the preparation of the single PS main needle of natural palm plant structure, please refer to figure 2

[0105] 1) Fixation in a semi-submerged state of needle-punched natural palmetto plants

[0106] Mix the PDMS prepolymer and the curing agent two-component glue used together to obtain a mixed glue, wherein: the weight ratio of the PDMS prepolymer glue to the curing agent glue is 10:1; for the mixed glue First use ultrasonic wave for 15 minutes to remove the large air bubbles in the mixed glue, and then vacuumize the mixed glue to a vacuum degree of 10 -2 pa, keep for 25 minutes to remove the small air bubbles in the mixed glue; put the mixed glue after defoaming on a hot stage with a temperature of 60°C for pre-crosslinking for 2 minutes to obtain a pre-crosslinked body; take a fresh natural yellow hair Palm plant acupuncture (structure such as figure 1 Shown in...

Embodiment 3

[0124] I. Preparation of PVDF needle-punched clusters imitating the natural plant structure

[0125] i imitate the preparation of the single PVDF main needle of the natural palm plant structure, please refer to figure 2

[0126] 1) Fixation in a semi-submerged state of needle-punched natural palmetto plants

[0127] Mix the PDMS prepolymer and the curing agent two-component glue used together to obtain a mixed glue, wherein: the weight ratio of the PDMS prepolymer glue to the curing agent glue is 10:1; for the mixed glue First use ultrasonic wave for 12 minutes to remove the large air bubbles in the mixed glue, and then vacuumize the mixed glue to a vacuum degree of 10 -3 Pa, keep it for 15 minutes to remove small air bubbles in the mixed glue; put the mixed glue after defoaming on a hot stage with a temperature of 60°C for pre-crosslinking for 4 minutes to obtain a pre-crosslinked body; take a fresh natural yellow hair Palm plant needles were placed on the surface of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Discharge power | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com