Coal bed gas well pulverized coal salvaging, water pumping gas production integrated tubular column

A coalbed methane well and drainage gas recovery technology, which is applied in the direction of drill pipe, casing, drilling equipment, etc., can solve the problems of increased workload, increased operating time and cost, fixed valves, floating valves, coal powder stuck faults, etc. , to achieve the effect of prolonging the normal working time of the pump, saving working time and improving comprehensive economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

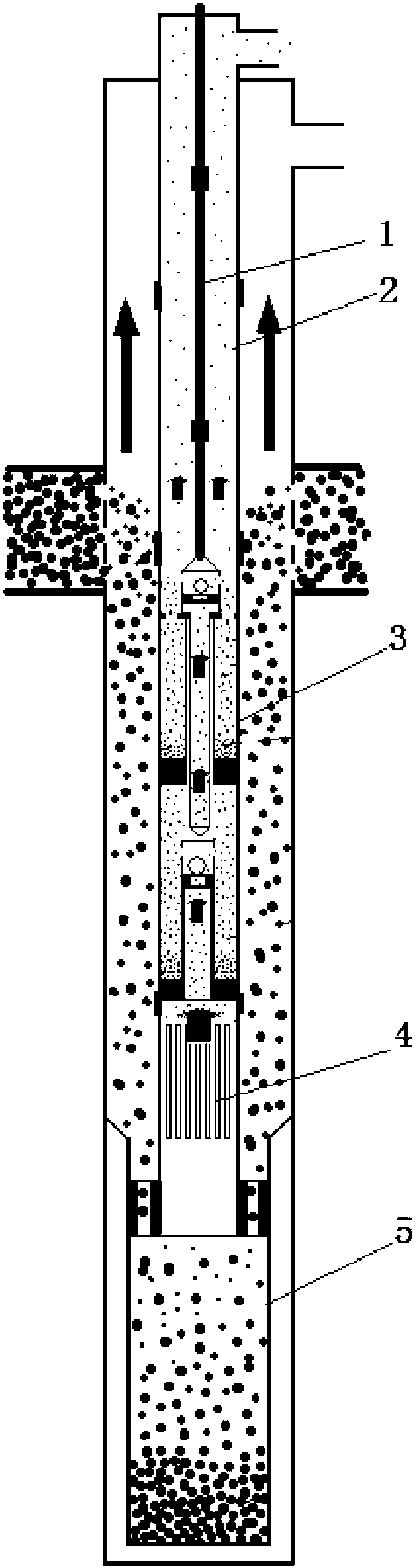

[0022] Embodiment 1: The present invention will be further described in detail by taking a coalbed methane well integrated pipe string for pulverized coal fishing, drainage and gas production used in an oil well with a casing inner diameter of 124 mm as an example.

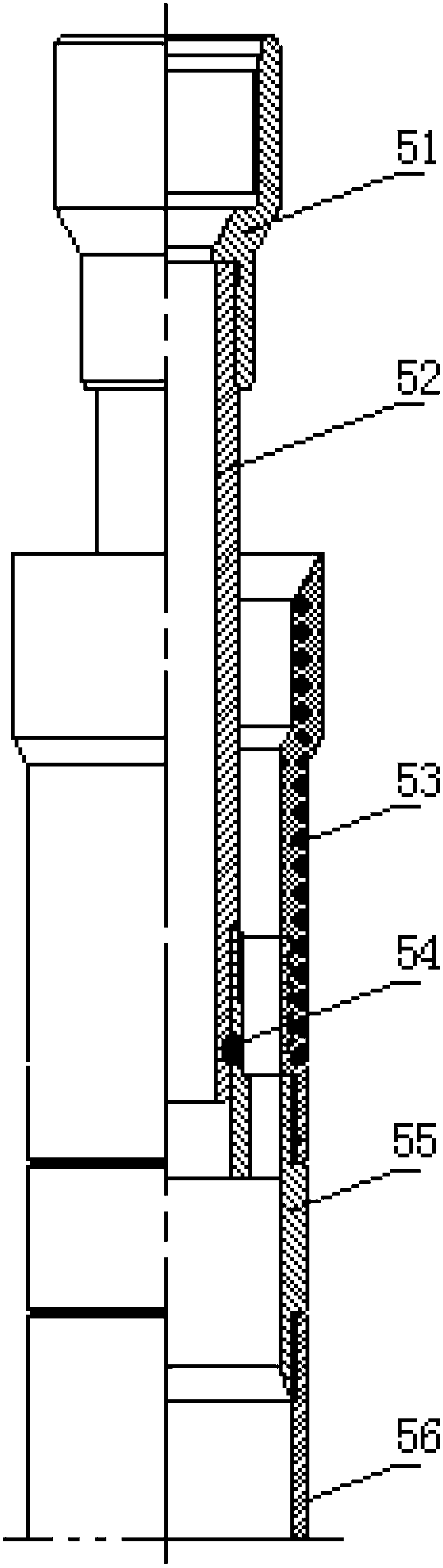

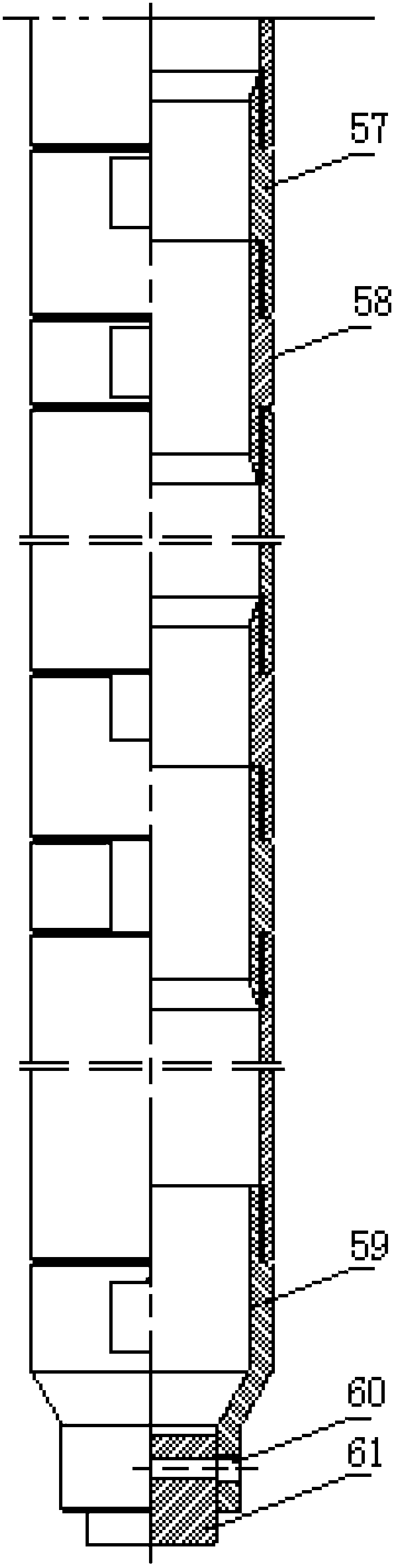

[0023] refer to figure 1 . Coal bed gas well scooping coal powder of the present invention, drainage and gas production integrated pipe string, mainly is made up of sucker rod 1, oil pipe 2, plunger pump 3 for coal bed gas well, screen pipe 4 and combined pulverized coal sand settling pipe 5. There is a combined pulverized coal sand settling pipe 5 in the casing of the coalbed gas well, and the combined pulverized coal sand settling pipe 5 is located at the lowest end of the pipe string, and is located at the lower part of the casing perforation section in the well. The depth of the lower end of the combined pulverized coal sand settling pipe 5 is 600m. (The depth of the bottom of the coal seam is 550m.)

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com