Device and method for detecting surface quality of printed matters

A surface quality and detection device technology, applied in the direction of optical testing flaws/defects, etc., can solve the problems of gloss detection, inability to detect, inaccurate overprinting, etc., and achieve the effects of not easy false detection, high detection efficiency, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

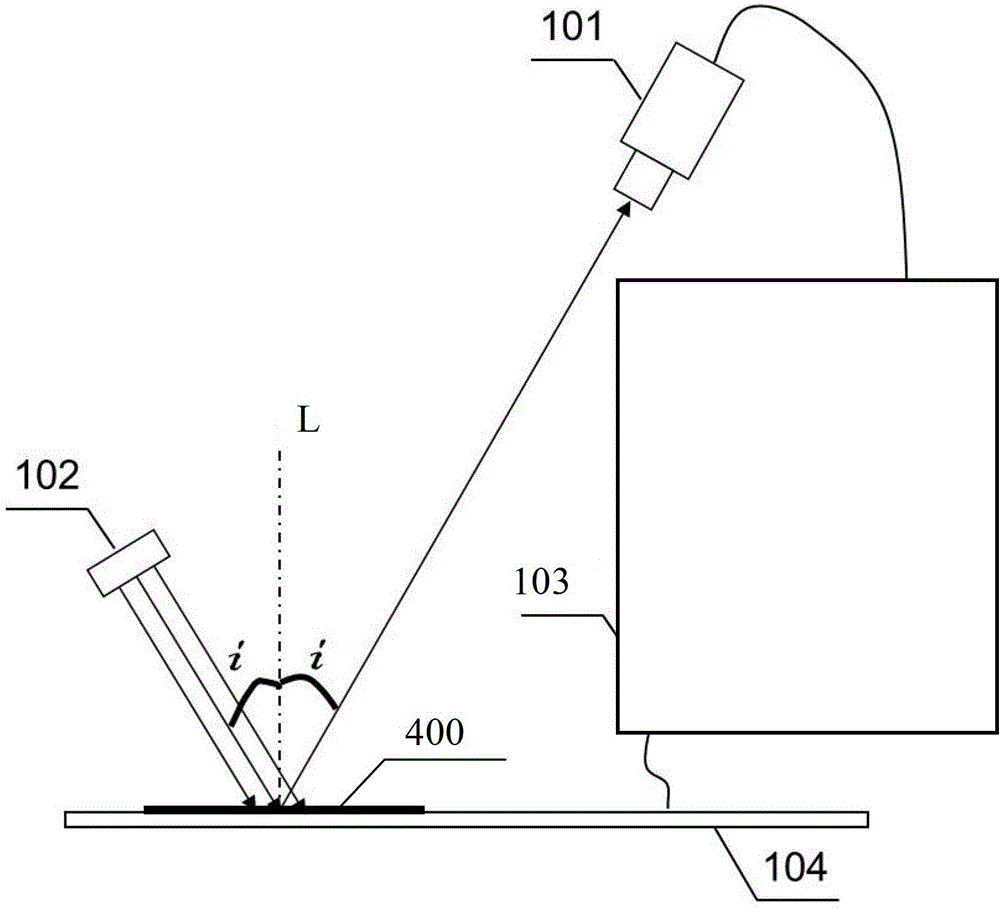

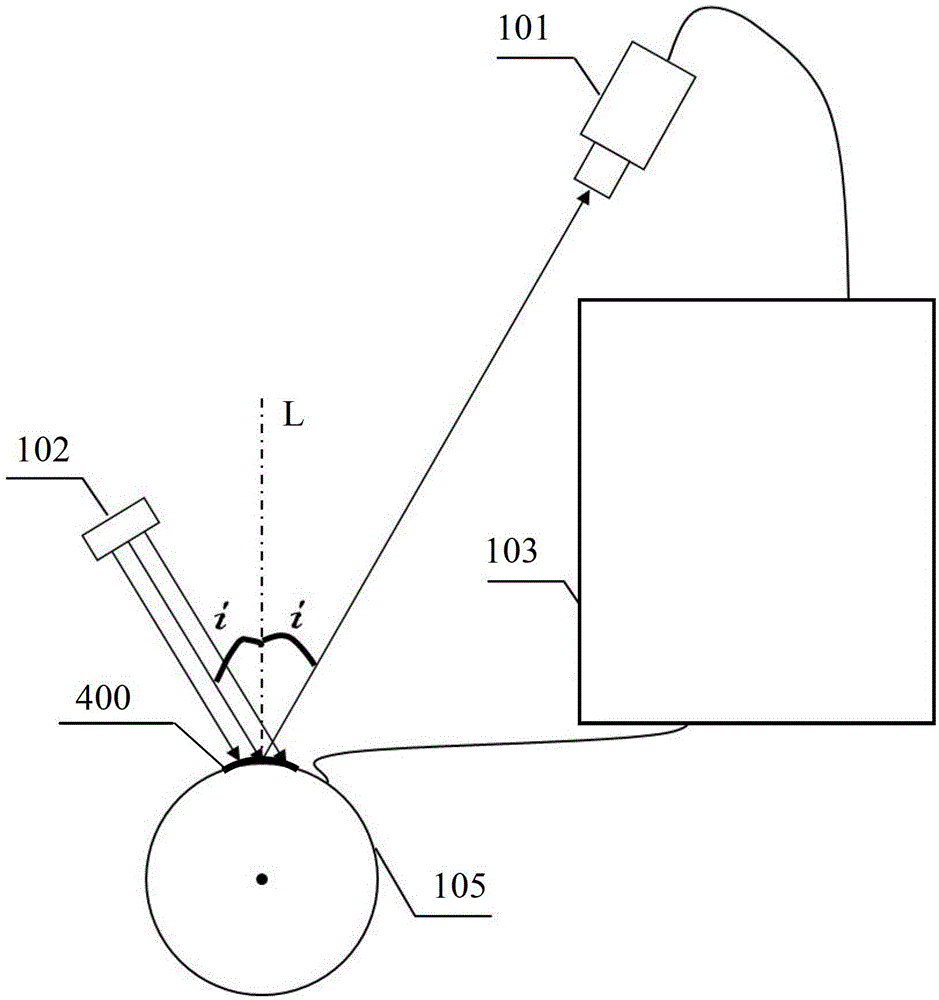

[0028] Such as figure 1 and figure 2 As shown, the present invention proposes a printed matter surface quality detection device, which includes a parallel uniform high-brightness light source 102 and an image capture device 101, and the control terminals of the parallel uniform high-brightness light source 102 and the image capture device 101 are respectively connected with a computer control system 103 The corresponding console connections, where:

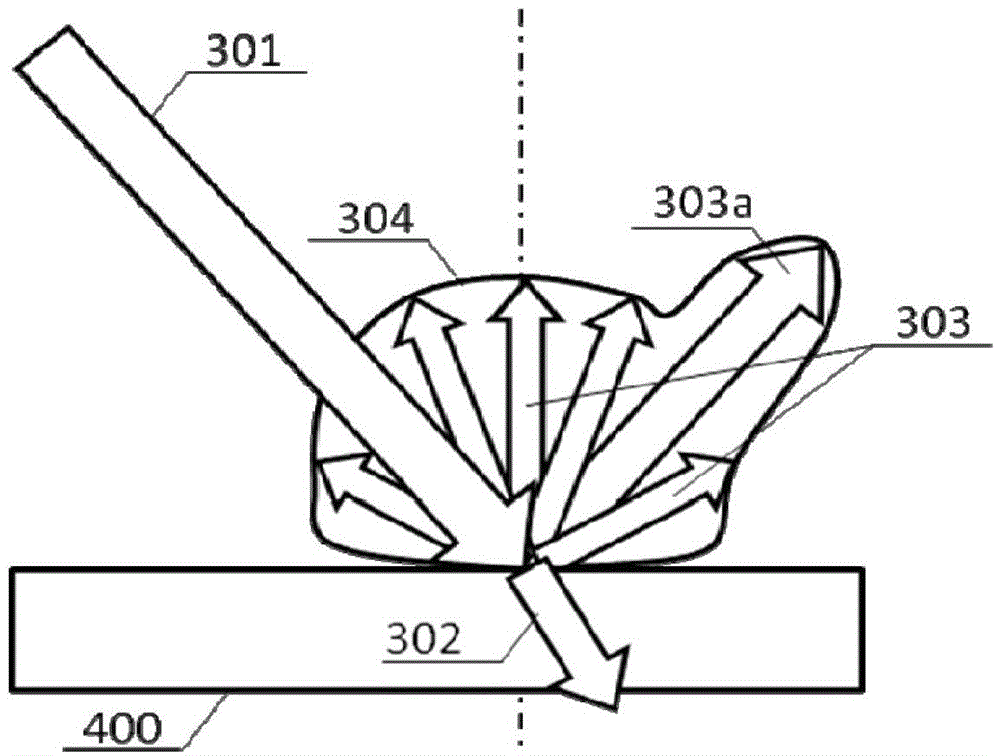

[0029] The parallel uniform high-brightness light source 102 emits uniform parallel high-brightness light to the detection area to illuminate the surface of the printed matter in the detection area (such as figure 1 and figure 2 The number 400 marked in the middle is the printed matter, and the upward side of the printed matter 400 is the surface of the printed matter referred to herein), and the incident angle of the uniform parallel highlight light incident on the surface of the printed matter in the detection area is a At ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle of incidence | aaaaa | aaaaa |

| angle of incidence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com