Sectional type groove type solar energy condenser

A trough solar and concentrator technology, applied in the field of solar concentrators, can solve the problems of high technological requirements and high cost of parabolic supports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

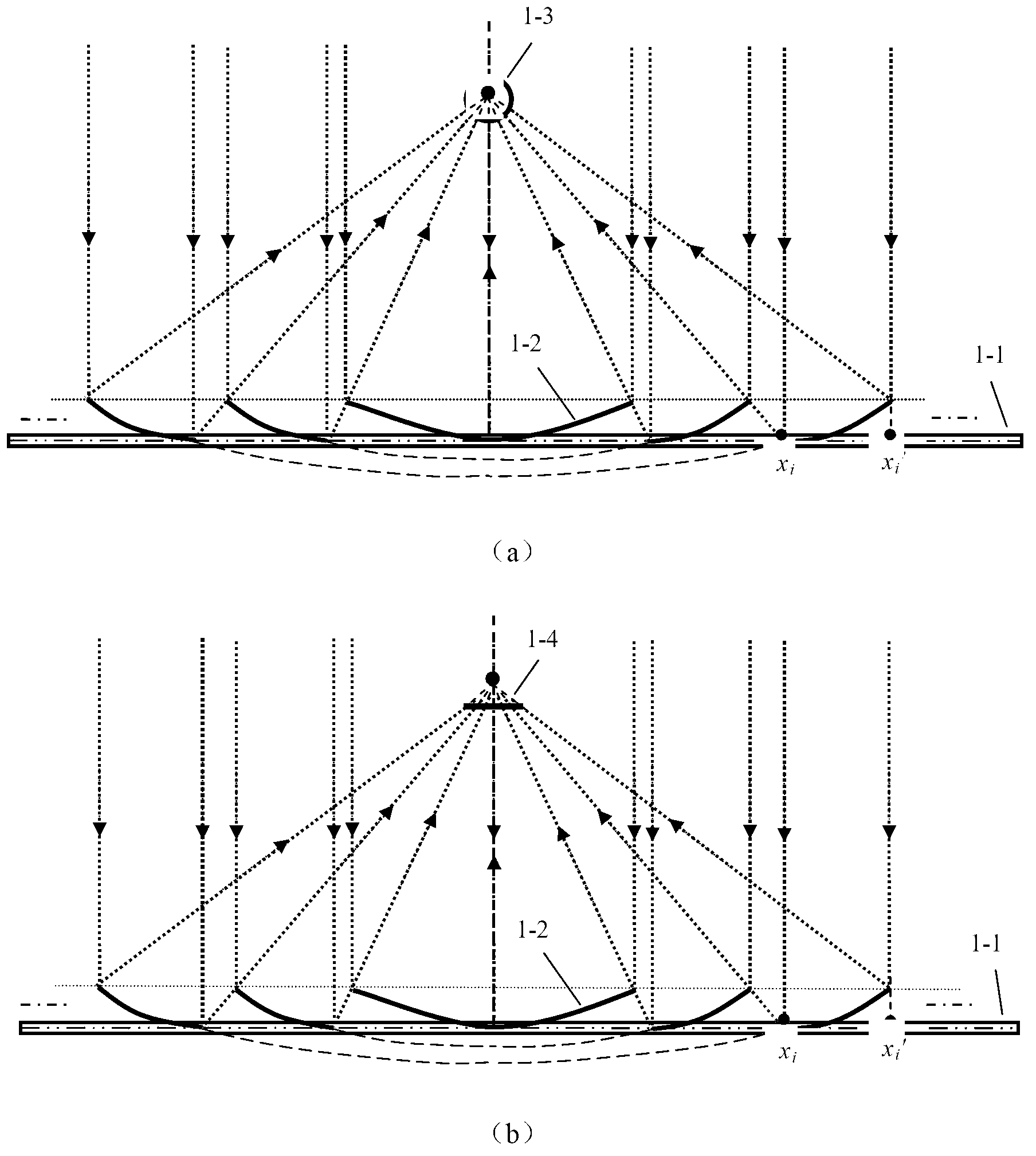

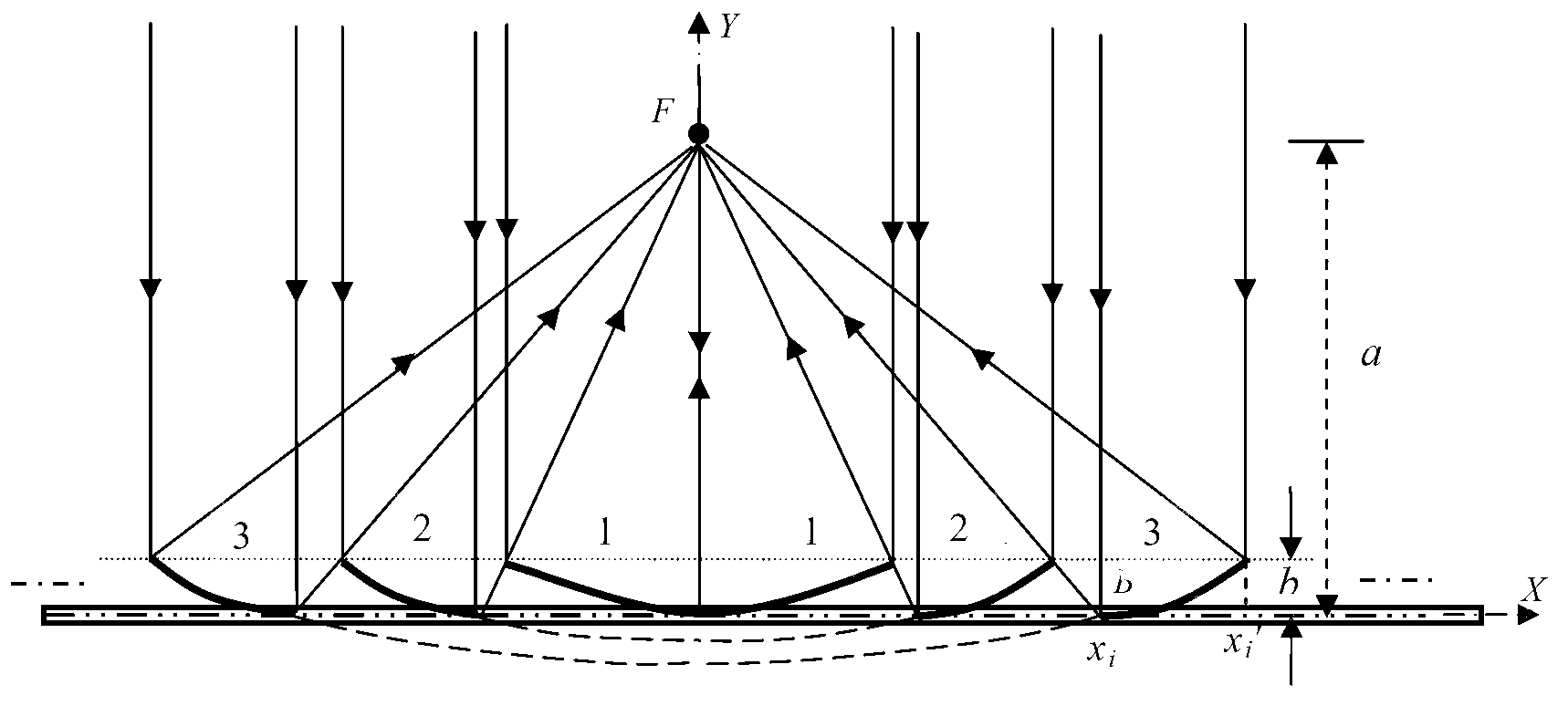

[0038] Embodiment 1, for the schematic structure of the segmented trough solar concentrator used for the heat utilization of the receiver as a cylinder, see figure 1 (a), the cylindrical light concentrating receiver 1-3 is a cylindrical vacuum tube heat collector, its radius is R, the vertical height between its center line and the flat frame 1-1 is a, and one of all parabolic reflectors 1-2 One side is fixed on the flat frame 1-1, and the displacement of the other side away from the flat frame 1-1 is b. like figure 1 As shown in (a), all the light rays reflected by the parabolic reflector 1-2 fall on the surface of the cylindrical light-condensing receiver 1-3, and the focal line of each parabolic reflector 1-2 is at the center of the cylindrical receiver 1-3 line position. The parabolic reflectors 1-2 are sequentially arranged on the plane frame 1-1, and the light reflected by the latter parabolic reflector 1-2 just passes through the edge of the previous parabolic refle...

Embodiment 2

[0049] Example 2, the structure of segmented trough solar concentrators for planar concentrating light and heat utilization can be found in figure 1 (b), the plate-shaped concentrating receiver 1-4 is a plate-shaped heat collector with a width of L, placed parallel to the plate frame 1-1, and the vertical height from the plate frame 1-1 is a, and all parabolic reflectors 1 One side of -2 is fixed on the flat frame 1-1, and the displacement of the other side away from the flat frame 1-1 is b. The light reflected by the parabolic reflector 1-2 all falls on the flat heat collector, and the focal lines of all the parabolic reflectors are at the same place above the flat heat collector. Because the sun's rays have a cone angle, the reflected light of the outermost parabolic reflector in the application falls as far as possible in the middle of the flat plate collector, so that as much light as possible can be irradiated on the surface of the flat plate collector. The parabolic re...

Embodiment 3

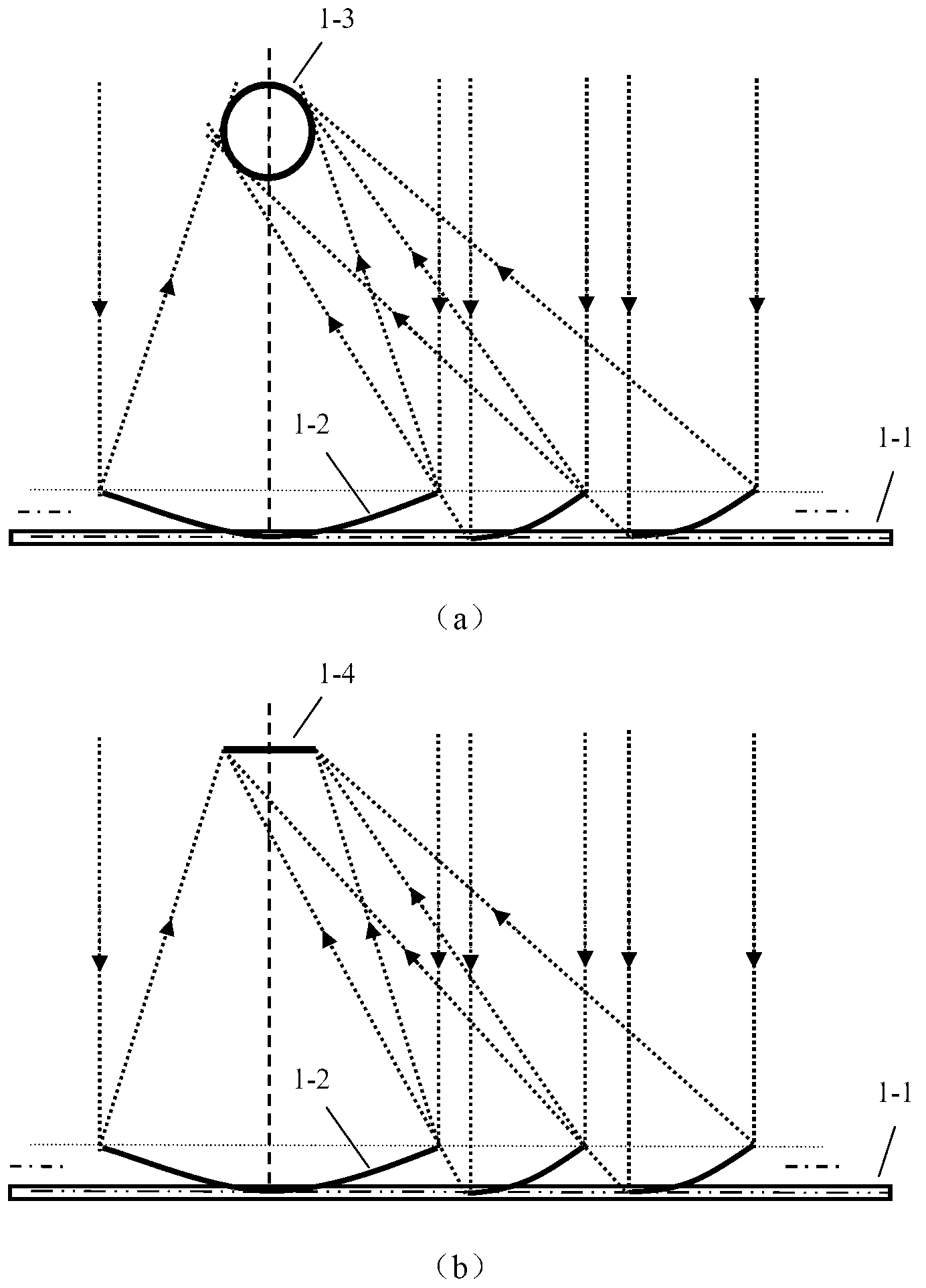

[0056] Embodiment 3, the structure of the segmented trough solar concentrator used for the heat utilization of the receiver as a cylinder is shown in image 3 (a), the radius of the cylindrical light concentrating receiver 1-3 is R, the vertical height between its center line and the flat frame 1-1 is a, and one side of all parabolic reflectors 1-2 is fixed on the flat frame 1-1 , the displacement of the other side away from the plate frame 1-1 is b. The edge of the light reflected by the parabolic reflector 1-2 falls on or within the boundary of the cylindrical light-concentrating receiver 1-3, and the parabolic reflector 1-2 is sequentially arranged on the plane frame 1-1, and the latter parabolic reflector 1-2 The reflected light just passes the edge of the previous parabolic reflector 1-2. The flat frame 1-1 is fixed on the sun tracking frame. The angle between the normal line of the plane frame of the single-axis solar tracker and the horizontal plane tracks the sun’s al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com