Degumming method of printed circuit board

A technology for printed circuit boards and baked boards, which is applied in the field of circuit board manufacturing, and can solve problems affecting quality, unclean removal of glue in plated through holes, resin shrinkage, etc., to meet quality requirements and reduce copper-free effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

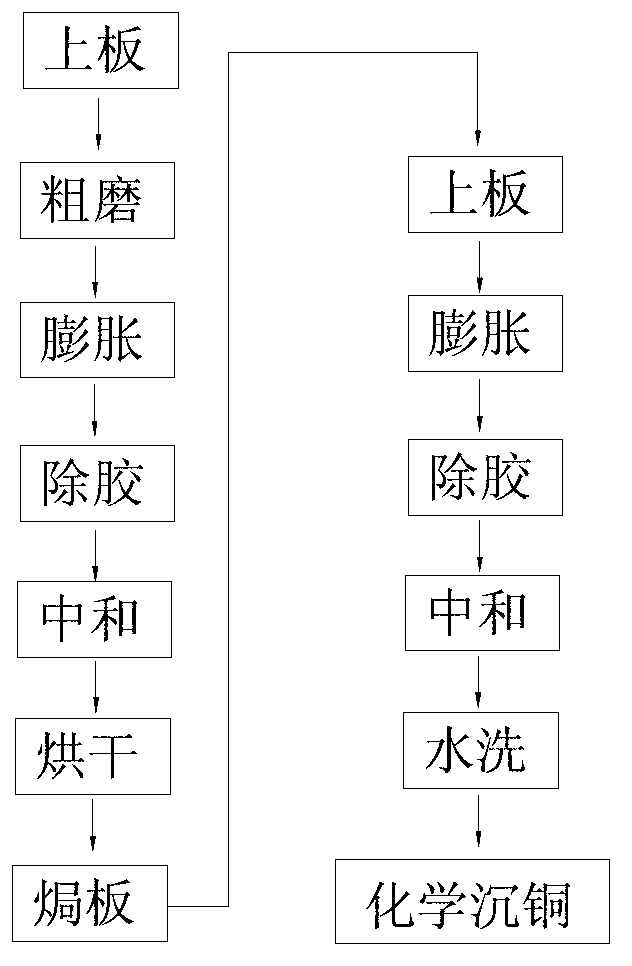

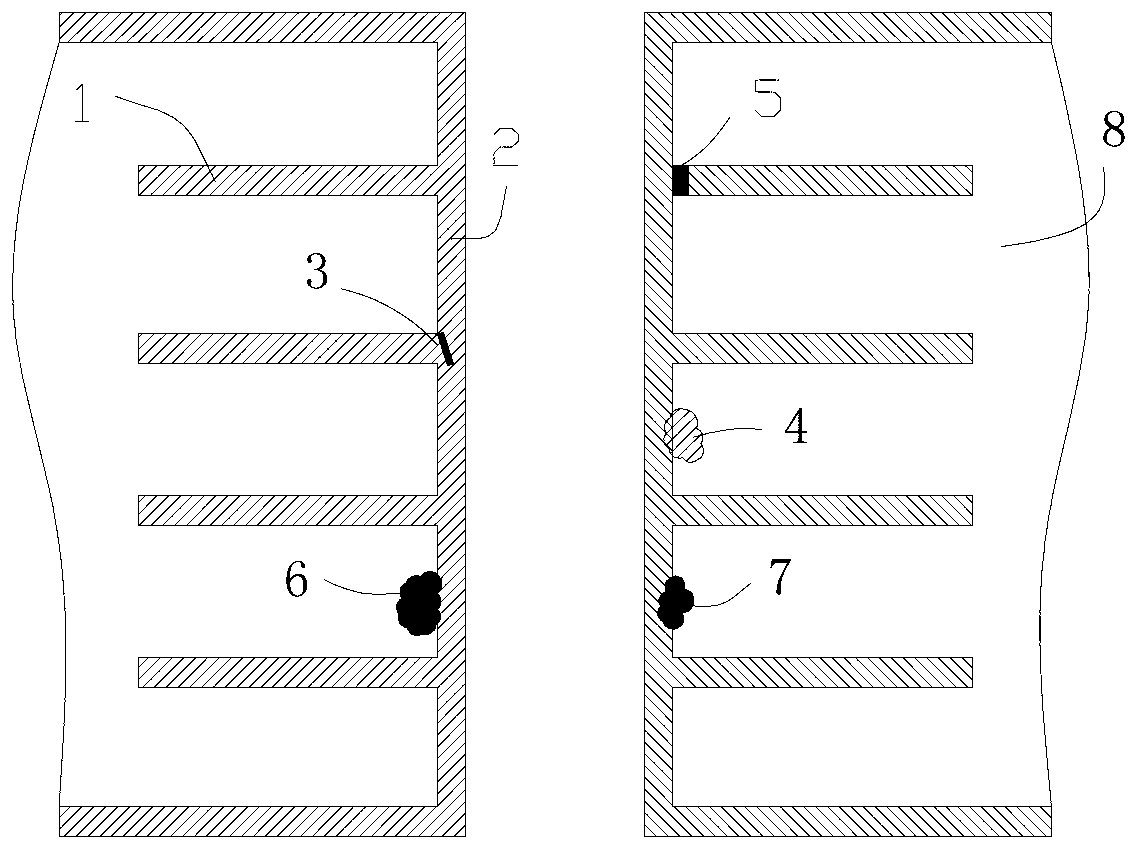

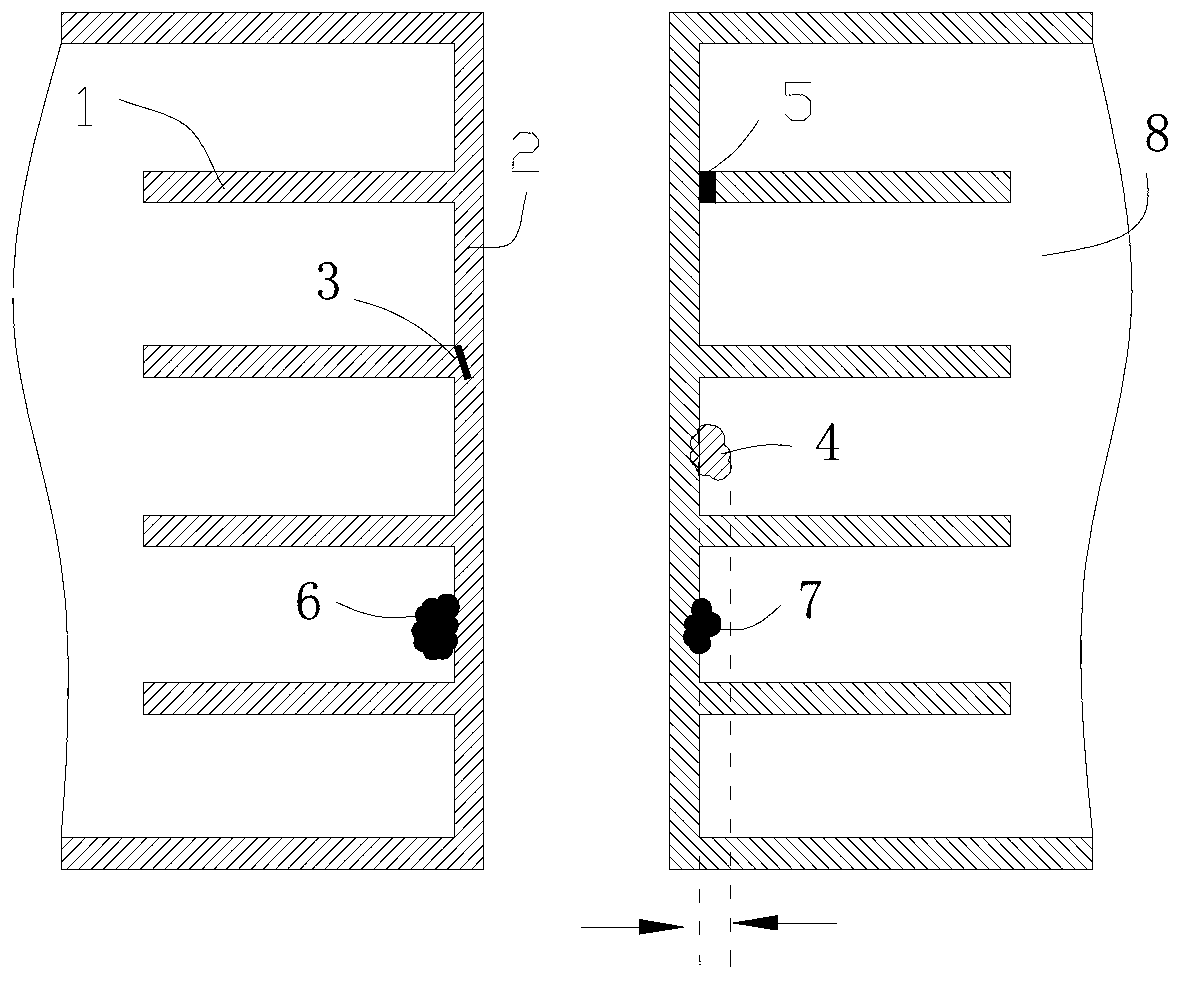

[0019] The deglue method of embodiment 1PCB circuit board

[0020] The PCB circuit board sheet material in this embodiment is GA-170-LL sheet material, and this GA-170-LL sheet material is the material with high Tg (170 ℃), low Z-axis expansion coefficient, is used for the lead-free manufacturing process PCB process. In this embodiment, the various raw materials used in the pre-degumming process and the degumming process are all conventionally used raw materials in the art, such as the expansion liquid is mainly ethylene glycol monobutyl ether (40-60%) and hydrogen Sodium oxide solution, the main function of the expansion fluid is to use ethylene glycol monobutyl ether to soften and bulk up the drilling slag and the dielectric material on the surface, so as to improve the effectiveness of the subsequent potassium permanganate oxidation. The degumming solution mainly contains potassium permanganate (KMnO 4 ) and sodium hydroxide.

[0021] The method for removing glue on the ...

Embodiment 2

[0049] The deglue method of embodiment 2PCB circuit board

[0050] In the pre-degumming process, the temperature of the expansion liquid is controlled at 74°C, and the expansion time is 5 minutes; KMnO in the degumming liquid 4 The concentration is 55g / L, the temperature is 81°C, and the degumming time is 9min; the baking temperature is 170°C, and the baking time is 2hrs; other methods and parameters are the same as in Example 1, and the degumming of the method in Example 2 is used. The rate is between the standard approval (the degumming rate is controlled at (0.366-0.916) mg / cm 2 ), in full compliance with product design and use requirements. After the degumming process of Example 2, there is no residual glue stain on the glass fiber; the resin surface is uniform and obviously honeycombed, and there is no resin cavity, and there is no glue slag and other residues on the inner copper surface, which has better degumming The effect can better meet the quality requirements of ...

Embodiment 3

[0051] The deglue method of embodiment 3PCB circuit board

[0052] In the pre-degumming process, the temperature of the expansion solution is controlled at 78°C, and the expansion time is 7 minutes; KMnO in the degumming solution 4 The concentration is 65g / L, the temperature is 85°C, and the degumming time is 11min; the baking board temperature is 175°C, and the baking board time is 2hrs; other methods and parameters are the same as in Example 1, and the degumming of the method in Example 3 is used. The rate is between the standard approval (the degumming rate is controlled at (0.366-0.916) mg / cm 2 ), in full compliance with product design and use requirements. After the degumming process of Example 3, there is no residual glue stain on the glass fiber; the resin surface is uniform and obviously honeycombed, and there is no resin cavity, and there is no glue slag and other residues on the inner copper surface, which has better degumming The effect can better meet the quality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com