Method and device for the simplified error processing in a machine tool

A technology of faults and machine tools, applied in the field of fault handling systems, can solve problems such as impossible, long description, and difficult, and achieve the effect of rapid distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

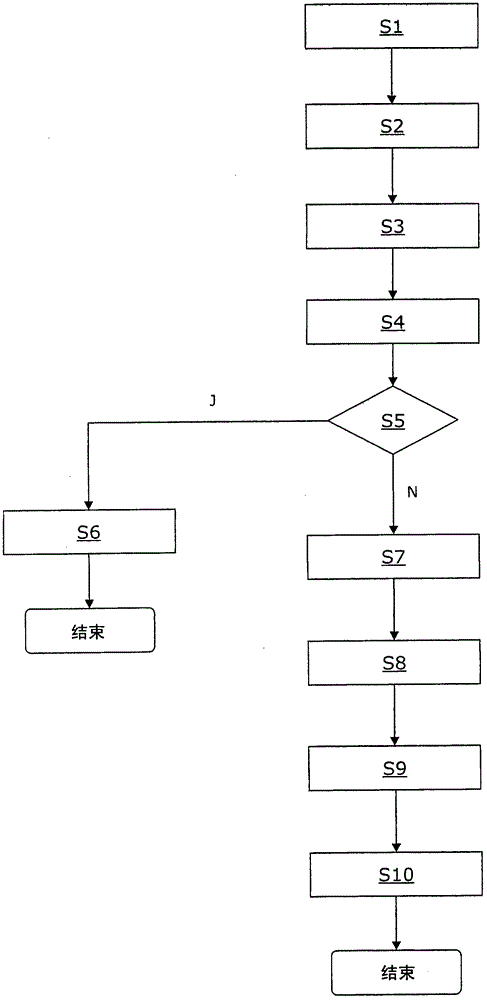

Method used

Image

Examples

Embodiment Construction

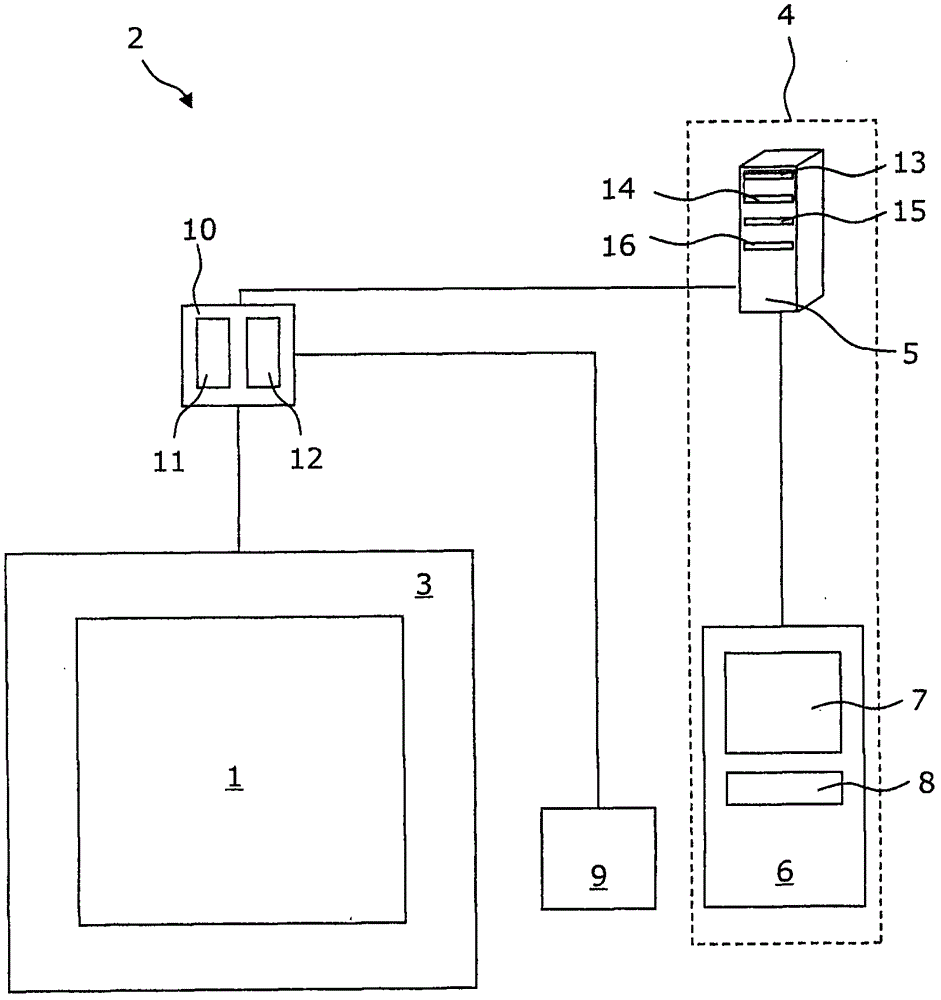

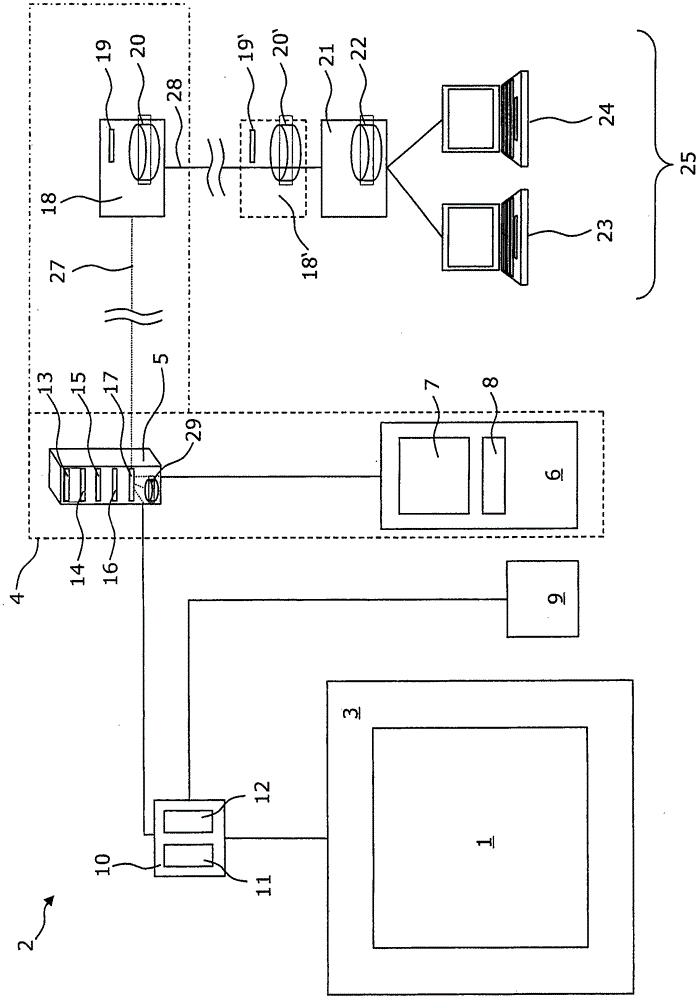

[0020] FIG. 1 shows a known machine tool 1 which is controlled by means of a numerical control unit 2 . For the automation of the machine tool 1 , an automation system 3 is provided, which is likewise controlled via the control device 2 .

[0021] On the hardware side, the control device 2 comprises an MMC (Man-Machine Communication) control unit 4, which has a control computer 5 designed as an industrial PC and an operating device 6, which has a screen 7 as a display unit and A keyboard 8 as an input unit. The control device 2 also includes a machine tool control panel 9 for manually operating the machine tool 1 and the automation device 3, and an NCU assembly 10 (Numerical Control Unit), which has an integrated NC control unit 11 and SPS (memory programming control ) control unit 12.

[0022] On the software side, the control device 2 includes an operating software 13 for controlling the machine tool 1, an operating software 14 for controlling the automation device 3, a pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com