Method for forming metal pattern on surface of insulator

A metal pattern and insulator technology, applied in the field of forming metal patterns on the surface of insulators, can solve problems such as increasing the production cost, and achieve the effects of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

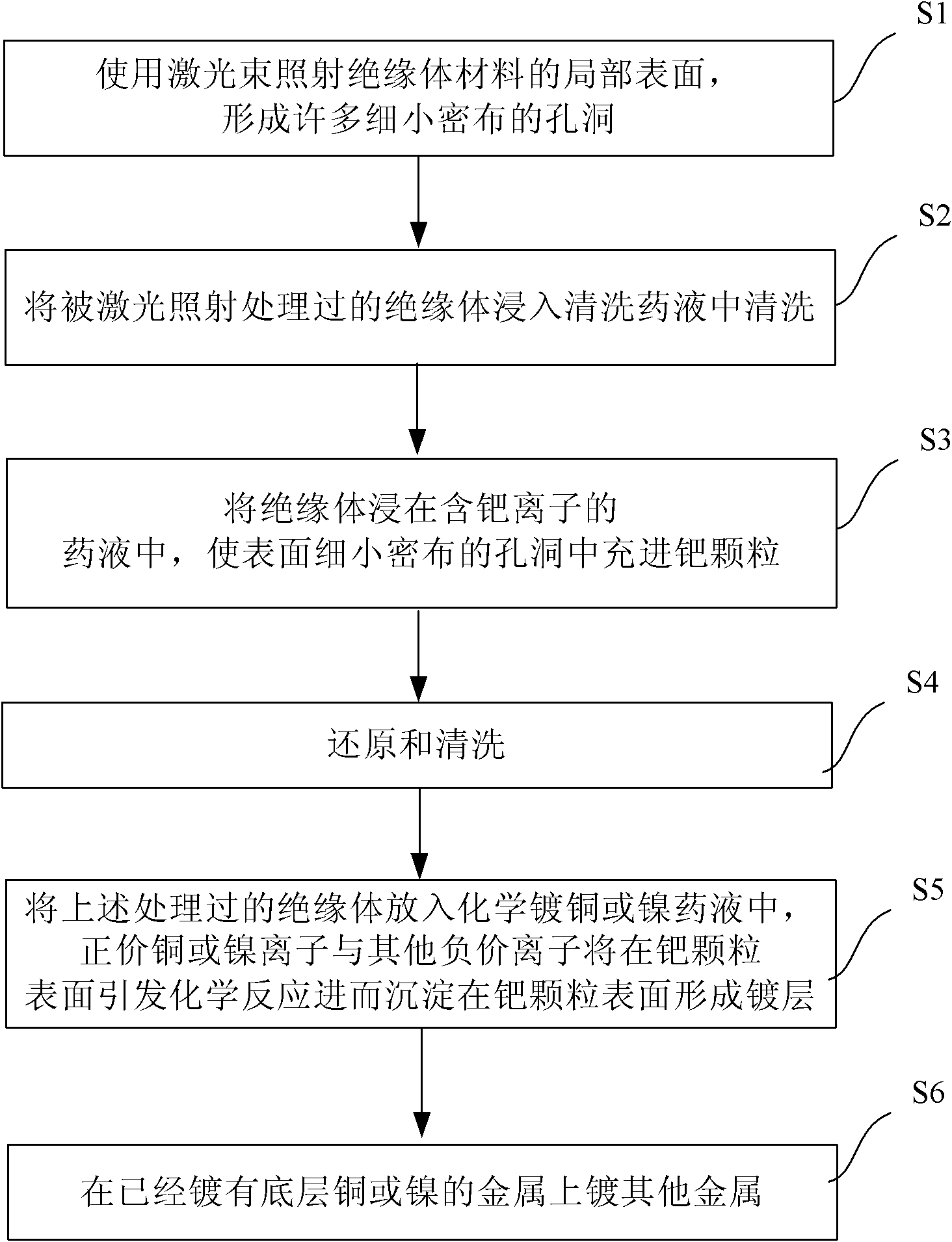

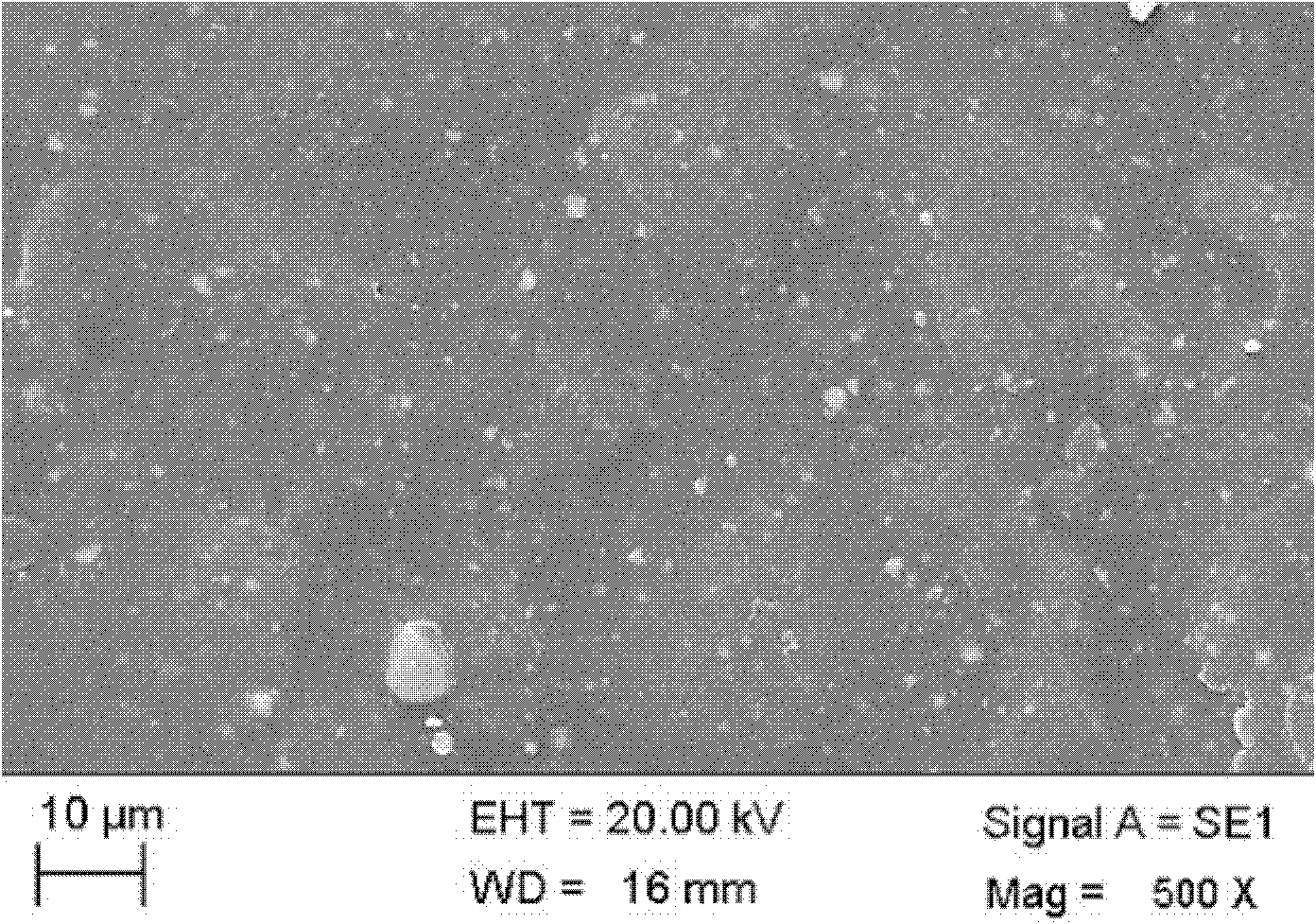

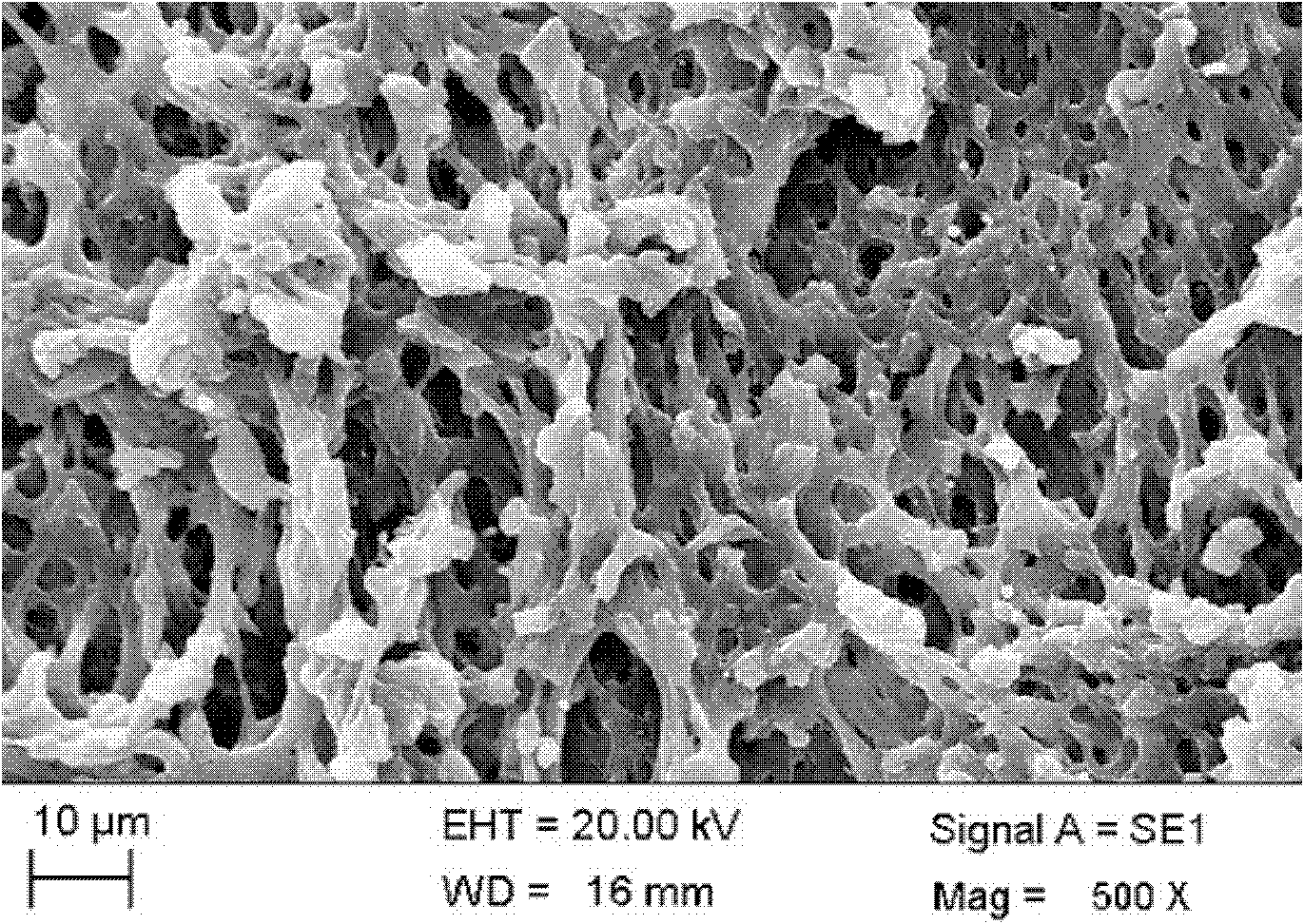

[0017] In summary, the present invention utilizes the property that a certain wavelength of laser light, such as infrared 1064nm laser light, can be absorbed by specific insulator materials, such as commonly used engineering plastics PC, PC / ABS, and PA, to generate heat. The laser beam is irradiated on the surface of the insulator, and the laser is focused on the surface of the insulator to form a very small spot. The laser hits the surface of the irradiated tiny area in the form of pulses. Form many fine and dense pores. Figure 2A and Figure 2B Shown is the surface morphology of the polycarbonate surface before and after laser irradiation. Such fine and dense pores can absorb metals such as palladium as an electroless plating medium, thus becoming a pavement for subsequent electroless plating.

[0018] Refer below figure 1 A flow of a method for forming a metal pattern on the surface of an insulator according to an embodiment of the present invention will be described. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com