Automatic draining device of gas extraction system

A technology of gas drainage and automatic water discharge, applied in the direction of gas discharge, safety devices, drainage, etc., can solve the problems of many mechanical transmission parts, low drainage efficiency, high failure rate, etc., achieve less transmission devices, realize automatic discharge, and avoid failures high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

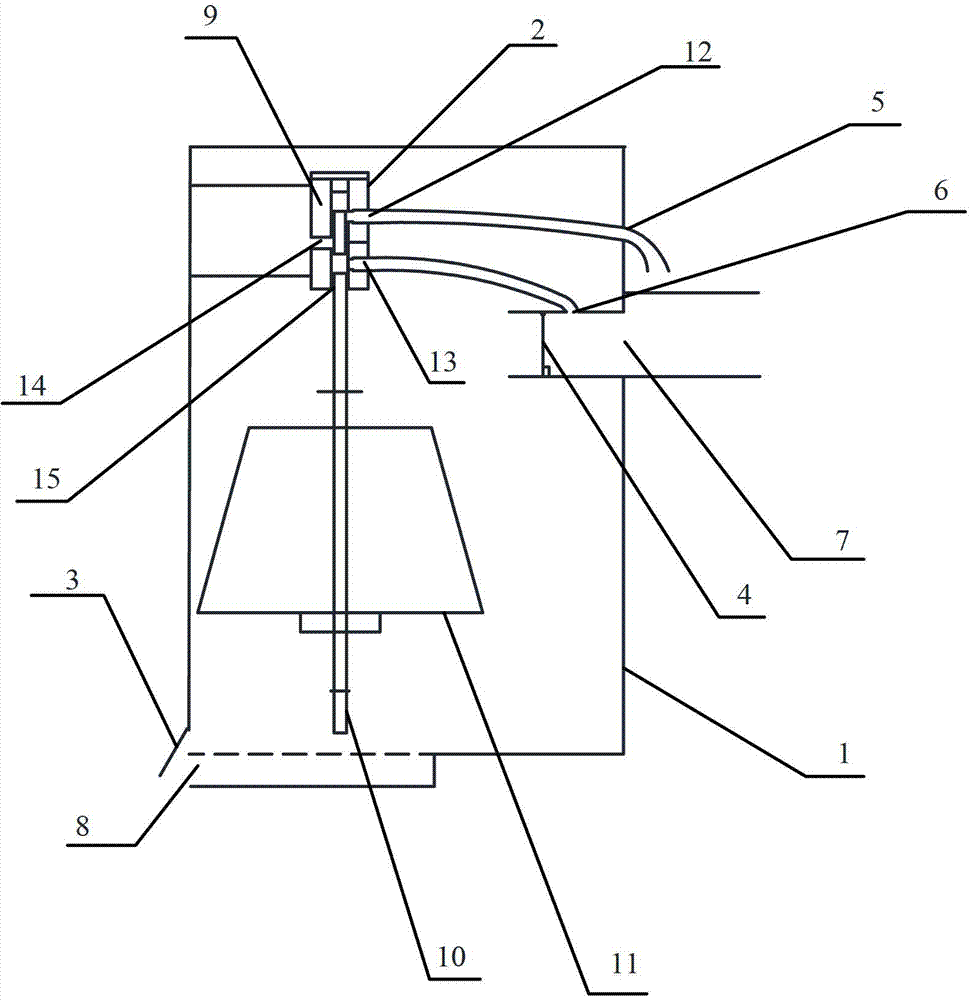

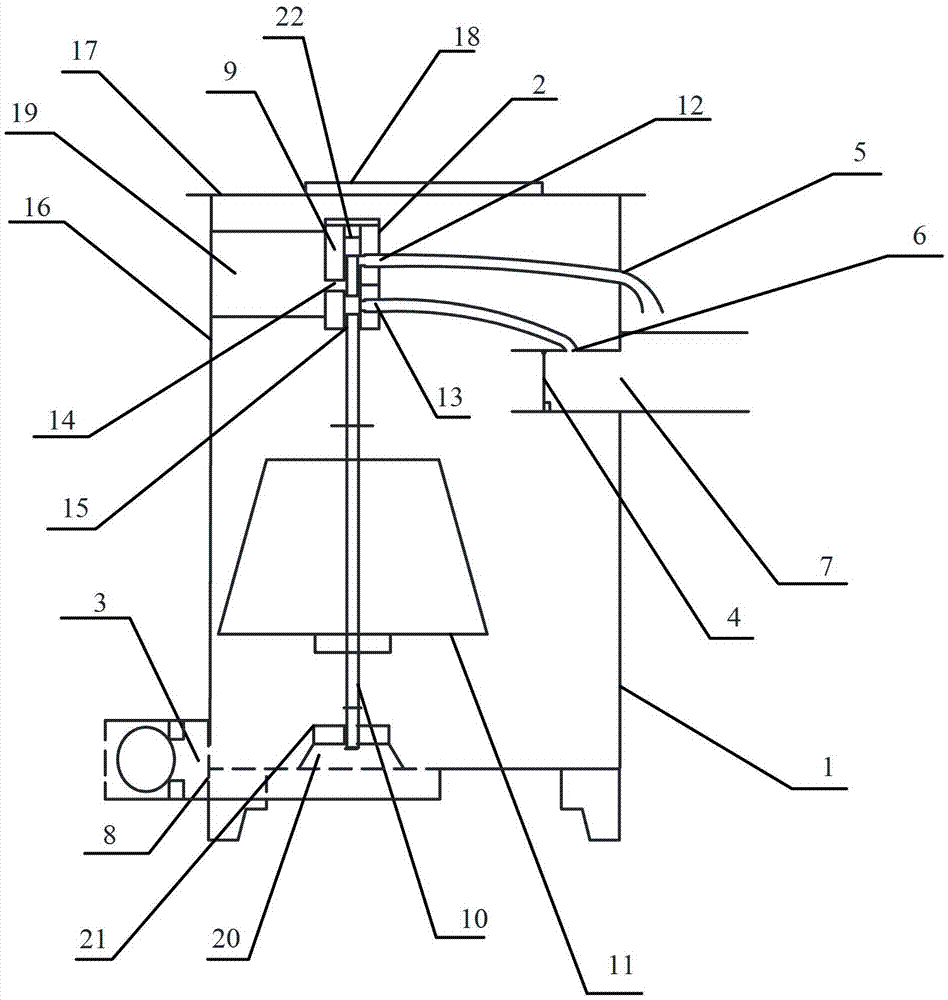

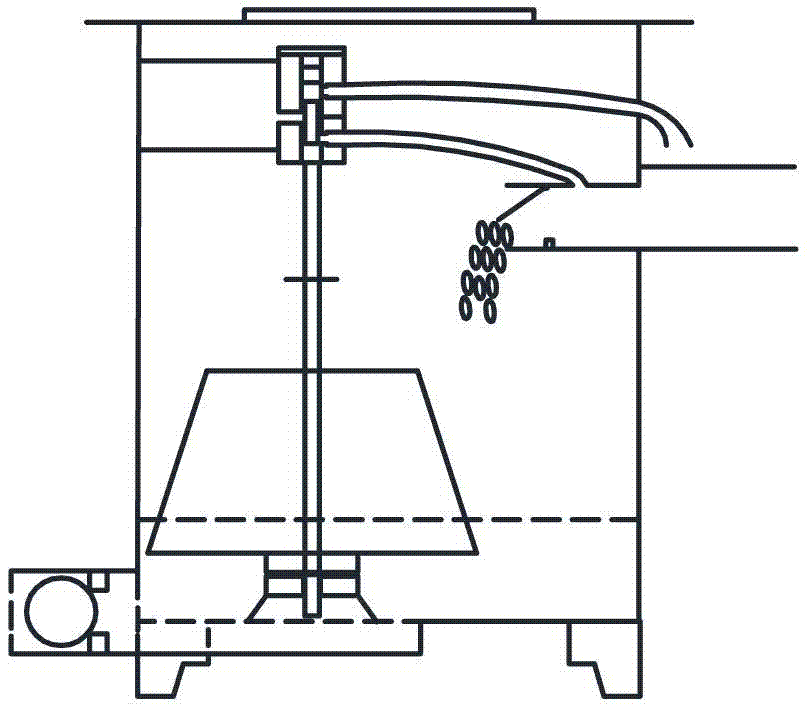

[0027] figure 1 It is a schematic structural diagram of an automatic water release device for a gas drainage system provided by an embodiment of the present invention. like figure 1 As shown, the automatic water discharge device of the gas drainage system in this embodiment specifically includes a water collection tank 1 , a piston switch device 2 , a first one-way valve 3 and a second one-way valve 4 . The water collection tank 1 has a first interface 5, a second interface 6, a water inlet 7 and a discharge outlet 8. The first interface 5 is connected to the outside atmosphere, the second interface 6 is connected to the gas drainage system, and the water inlet 7 is opened in the water collection tank 1. The upper part of the water inlet 7 is connected with the discharge port 8 of the gas drainage system, and the discharge port 8 is set at the bottom of the water collection tank 1. The piston switch device 2 is arranged in the water collection tank 1 , and the piston switch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com