Hydrostatic hybrid drive system

A drive system and hybrid technology, applied in hybrid vehicles, fluid hybrid vehicles, pneumatic power devices, etc., can solve problems such as reducing the driving power of internal combustion engines, and achieve the effect of compensating for compression loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

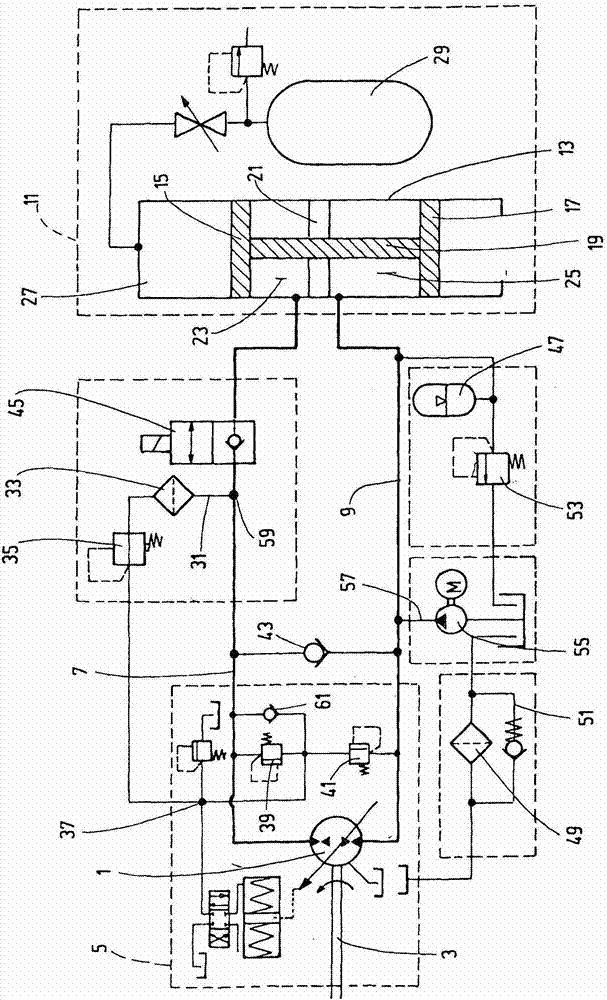

[0019] figure 1 A hydraulic circuit diagram of an exemplary embodiment is shown, in which a pump-motor unit is marked with 1, which is driven in a constant direction of rotation by the internal combustion engine of the relevant vehicle, which, like the rest of the vehicle components, is not shown . In the present example, the pump-motor unit 1 is directly driven by a schematically represented crankshaft 3 of an internal combustion engine. The pump-motor unit 1 is an axial piston machine whose swivel angle is adjustable in both swivel directions beyond a neutral zero position by means of an electrohydraulic control unit 5 so that the pump-motor unit 1 It is possible to work both in pump operation and in motor operation while maintaining a constant direction of rotation. The control unit 5 interacts via an interface (not shown) with the electronic engine management system of the vehicle corresponding to the prior art.

[0020] A first working line 7 is connected to the high-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com