Method For Determining And Monitoring The Level Of A Medium In A Container According To A Runtime Measurement Method

A measurement method, technology of propagation time, applied in the field of confirming and monitoring the fill level of a medium in a container by means of propagation time measurement, capable of solving the problems of unresolved measurement value confirmation, container overfilling, pumping dry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

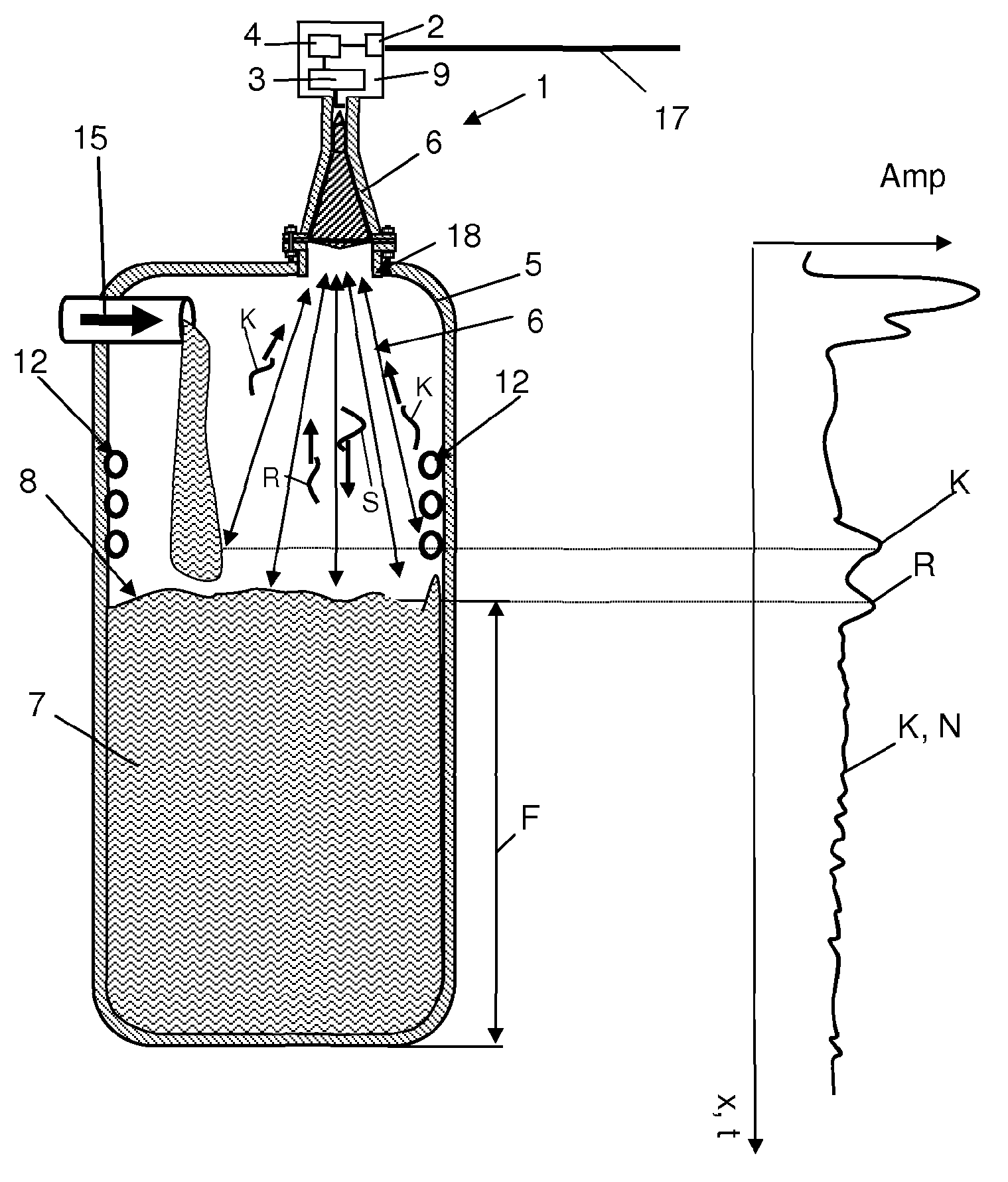

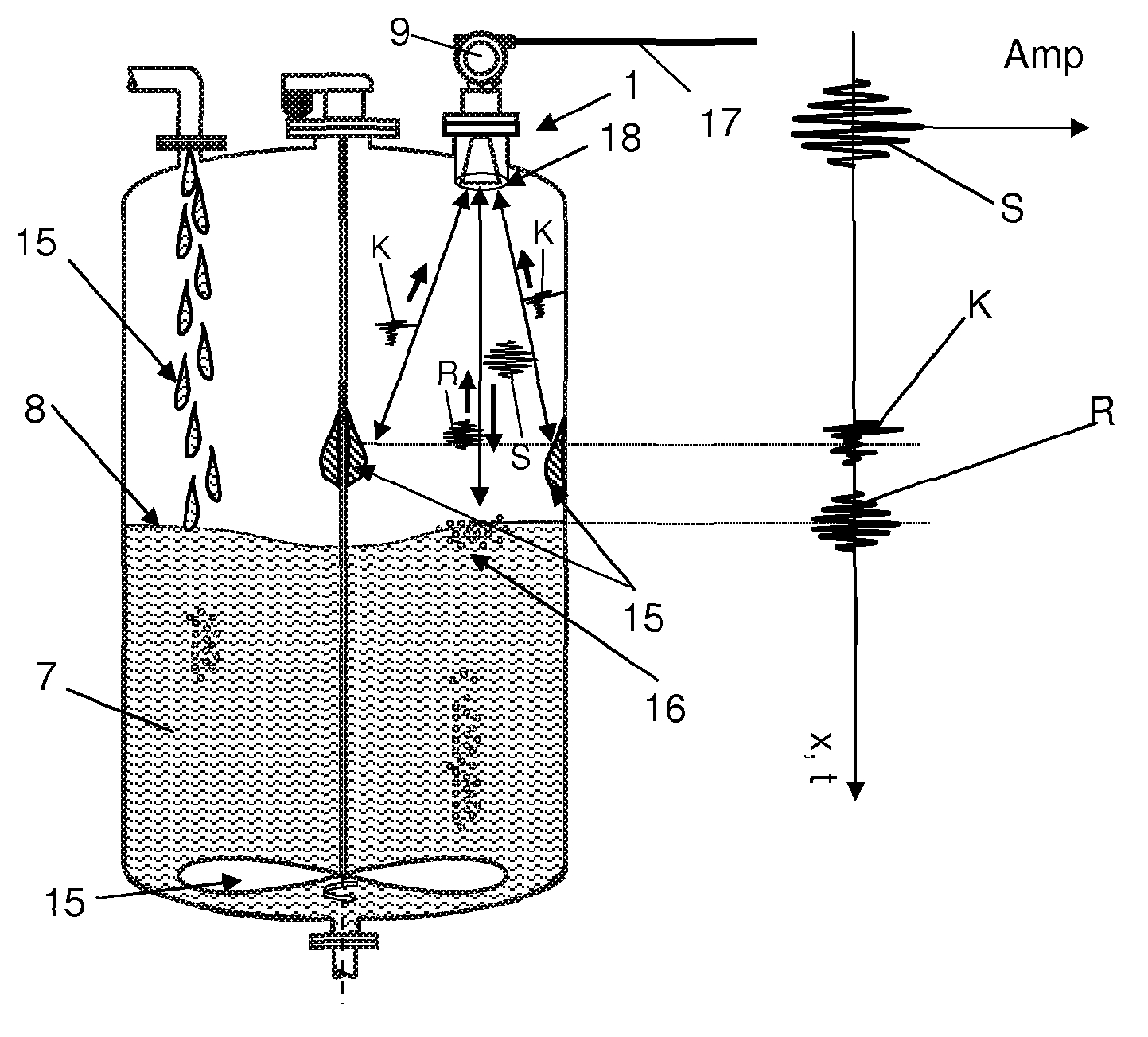

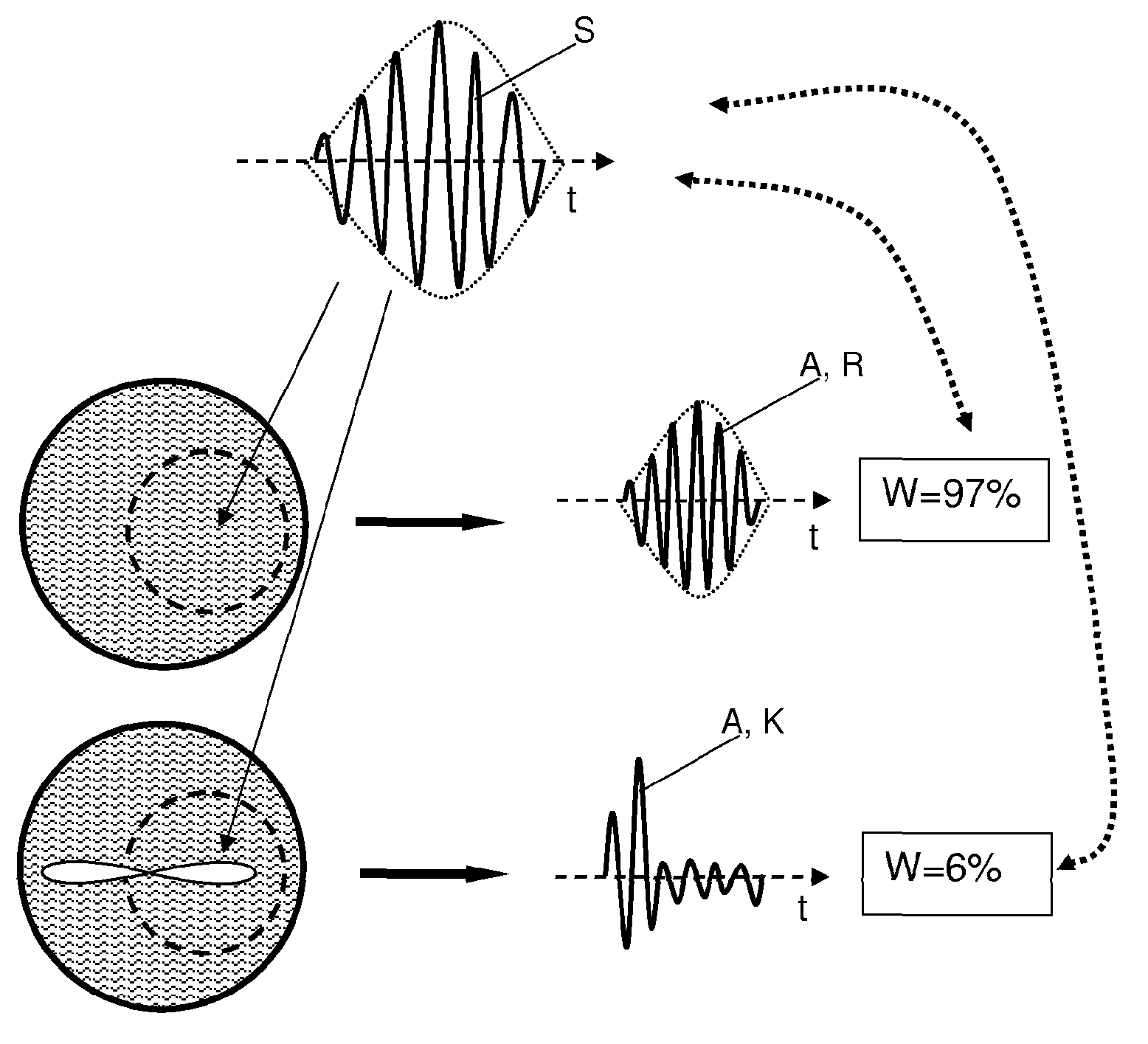

[0034] figure 1 A measuring device 1 operating according to the transit time measurement method for determining the fill level F of the medium 7 is shown. The measuring device 1 is mounted on the container 5 via the nozzle. The illustrated measuring device 1 comprises: a transmitting / receiving element 6 radiating freely into the process space; and a measuring transmitter 9 . The measuring transmitter 9 comprises: at least one transmitting / receiving unit 3 generating and receiving measuring signals; a control / evaluating unit 2 for signal processing of the measuring signals and for controlling the measuring device 1; and, via a bus system and the measuring device 1 communication unit 4 for energy supply control communication. For example, a memory element in which measurement parameters and echo parameters are stored and in which measurement factors and echo factors are stored is integrated in control / evaluation unit 2 . The transmitting / receiving element 6 is, for example, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com