ABC dry powder extinguishant production technology

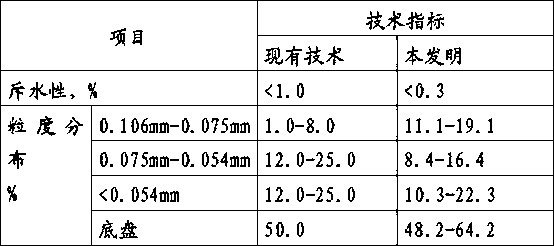

A dry powder fire extinguishing agent and production process technology, applied in fire protection equipment and other directions, can solve the problems of coarse particle size, not very long shelf life, and unsatisfactory dry powder fire extinguishing effect, and achieve long shelf life, good particle size and good silicification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

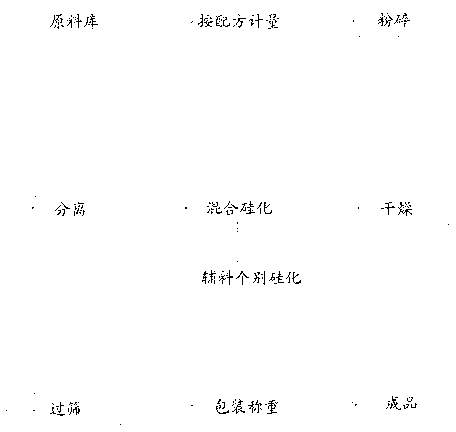

[0025] Such as figure 1 Shown, a kind of ABC dry powder fire extinguishing agent production process, described dry powder fire extinguishing agent comprises the ammonium phosphate that mass percentage composition is 80%, described technology comprises the steps:

[0026] (1) Weigh the raw ammonium phosphate;

[0027] (2) Add the above-mentioned ammonium phosphate to the pulverizer for pulverization;

[0028] (3) Separating the above-mentioned pulverized raw materials through a separation device;

[0029] (4) Pass the separated ammonium phosphate into the silicification equipment, add 1% of the mass percentage of silicone oil and auxiliary materials mica, white carbon black and talcum powder, the mass percentage of the said auxiliary materials mica is 5%, the mass percentage of white carbon black The percentage is 3% and the mass percentage of talcum powder is 11% to perform siliconization treatment respectively, and then put into the siliconization equipment after performing...

Embodiment 2

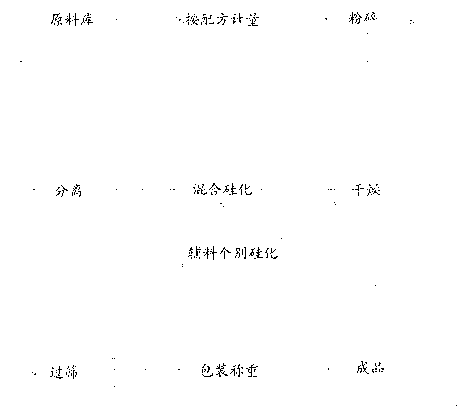

[0036] Such as figure 2 As shown, the rest are the same as in Example 1, the difference is that in the above separation process, the dry powder with a qualified particle size enters the next process flow, otherwise it is re-entered into the pulverizer for pulverization.

[0037] Similarly, the dry powder whose particle size meets the requirements after sieving enters the next process flow, otherwise it will be re-entered into the pulverizer for pulverization.

[0038] The technical solution of this embodiment can not only make the production process of the ABC dry powder fire extinguishing agent achieve the purpose of having a better fire extinguishing effect, but also make the dry powder have better water repellency, no obvious water absorption, and not easy to agglomerate, so that the shelf life is longer. The matching degree is good, and the purpose of fully utilizing the raw materials can also be achieved, saving costs.

Embodiment 3

[0040] All the other are identical with above-mentioned embodiment, difference is that described dry powder fire extinguishing agent comprises the ammonium phosphate that mass percent composition is 84.4%, the silicone oil of 0.1%, the mica of 3%, the white carbon black of 0.5% and the talcum of 12% pink.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com