Cast-in-situ terrazzo grade level polishing waste slurry recovery device

A recycling device and waste slurry technology, applied in grinding/polishing safety devices, filter circuits, grinding/polishing equipment, etc., to achieve reliable interception, prevent secondary pollution, and save water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

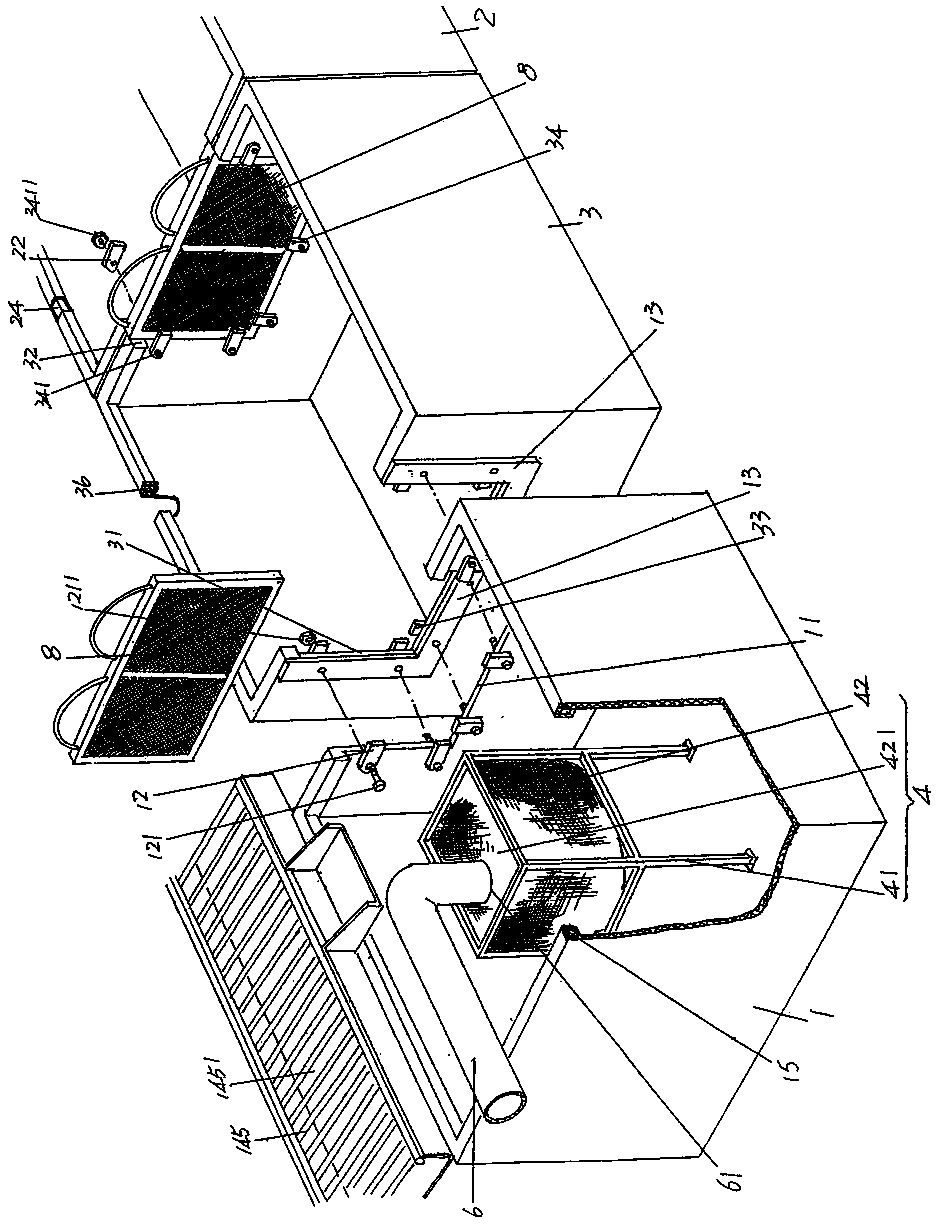

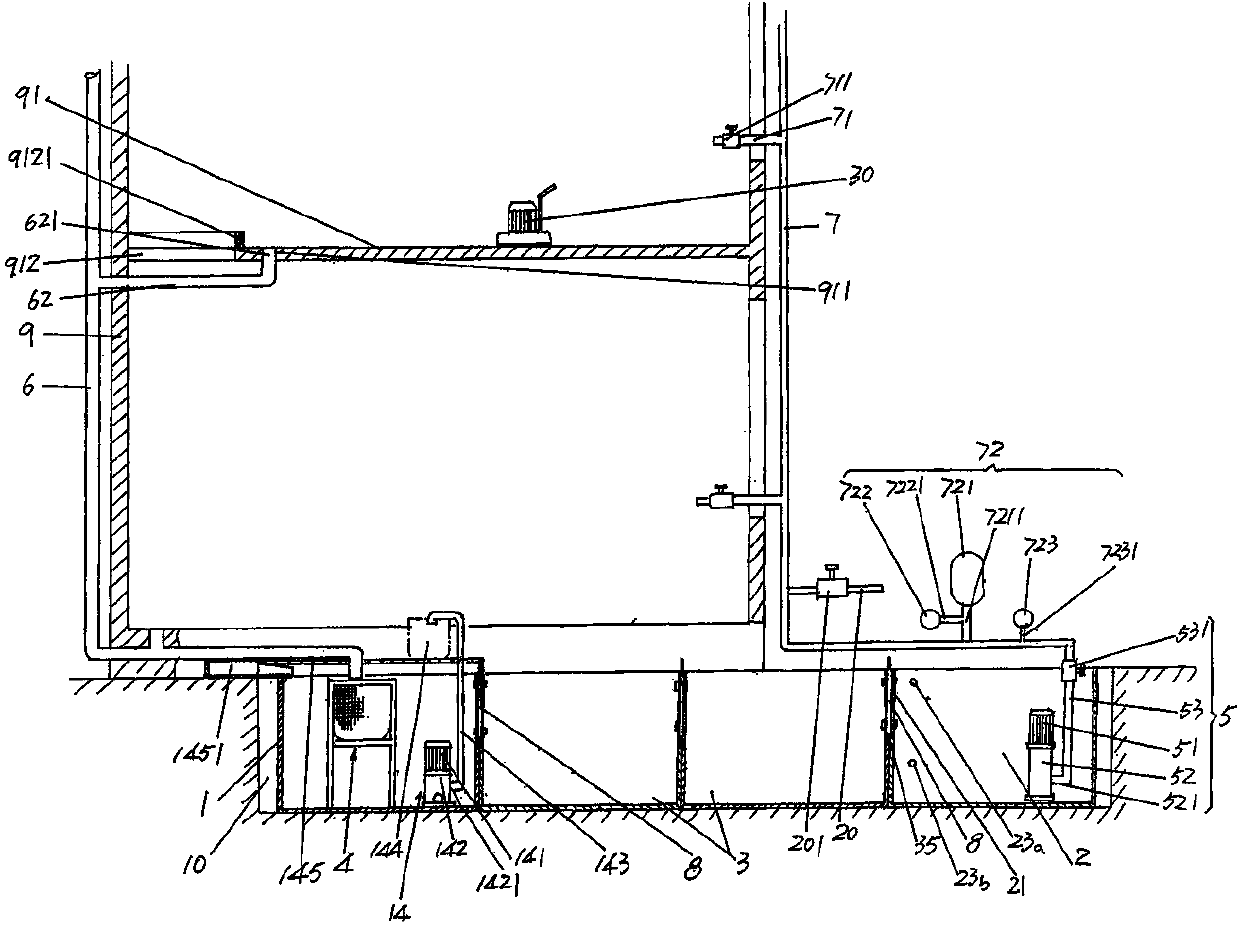

[0023] See figure 1 with figure 2 , the waste slurry collection box 1, the clean water reuse box 2 and the sedimentation box 3 are given, wherein figure 1 It is shown that there are two settling tanks 3, but of course it can be increased to more than two or reduced to only one according to specific circumstances. Above the side wall of the waste slurry collection box 1 facing the settling tank 3 and in the middle, there is a first overflow port 11 with a shape that is generally U-shaped ( figure 2 shown), and a settling tank 3 adjacent to the waste slurry collection box 1 faces above the side wall of the waste slurry collection box 1 and opens a shape and size corresponding to the first overflow port 11 at the position corresponding to the first overflow The second overflow port 31, which is completely the same as the flow port 11, is also provided with a shape and size in the middle of a sedimentation tank 3 adjacent to the clean water reuse tank 2 facing the side wall of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com