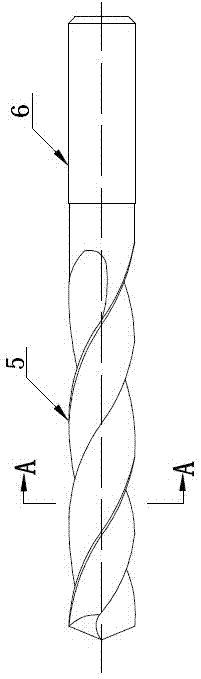

Solid carbide drill chip breaker groove for steel part and design method thereof

A solid carbide and design method technology, applied in metal processing equipment, drilling/drilling equipment, twist drills, etc., can solve problems such as unfavorable chip removal, cutting entanglement, and large cutting heat, so as to reduce temperature and prevent The effect of winding and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] The design method for the chip breaker of solid carbide drill bits for steel parts includes the following process steps:

[0024] 1. The selection of five-axis grinding center equipment is the necessary equipment for making carbide tools;

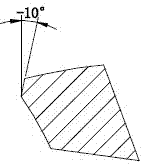

[0025] 2. The grinding wheel is made of diamond grinding wheel, the type of grinding wheel is 1V1 (75°);

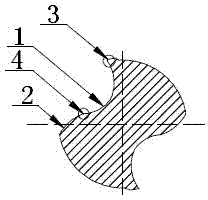

[0026] The following are the specific parameters of the chip breaker cross section R of the drill bit that should be achieved for chip rolling and chip breaking. The specific parameters are as follows:

[0027] Blade size Groove bottom radius Blade size Groove bottom radius Φ3 R1.23 Φ4 R1.45 Φ5 R1.71 Φ6 R2.02 Φ7 R2.31 Φ8 R2.6 Φ9 R2.89 Φ10 R2.99 Φ11 R3.25 Φ12 R3.41 Φ13 R3.61 Φ14 R3.81 Φ15 R4.06 Φ16 R4.1 Φ17 R4.18 Φ18 R4.25 Φ19 R4.42 Φ20 R4.6 Φ21 R4.68 Φ22 R4.75 Φ23 R4.9 Φ24 R5.1 Φ25 R5.41

[0028] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com