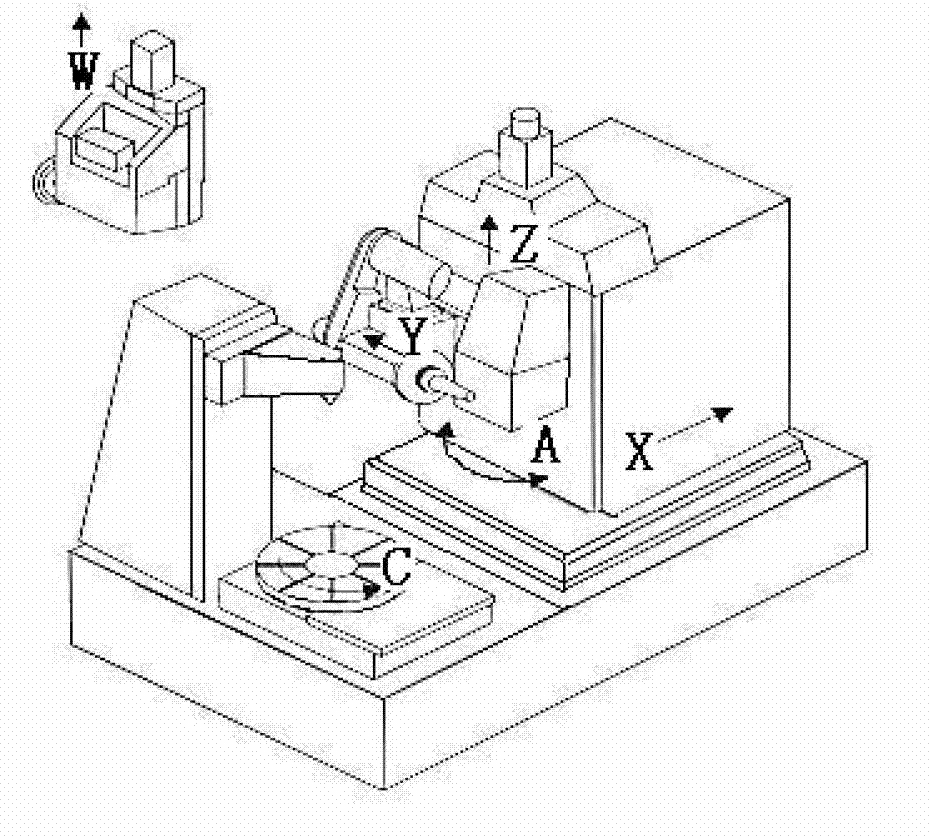

Automatic compensating method of gear clamping eccentric error of gear grinding of numerical control (NC) formed grinding wheel

An automatic compensation and eccentricity error technology, applied in the direction of gear tooth manufacturing devices, gear teeth, components with teeth, etc., can solve the problems of difficult adjustment and affecting processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

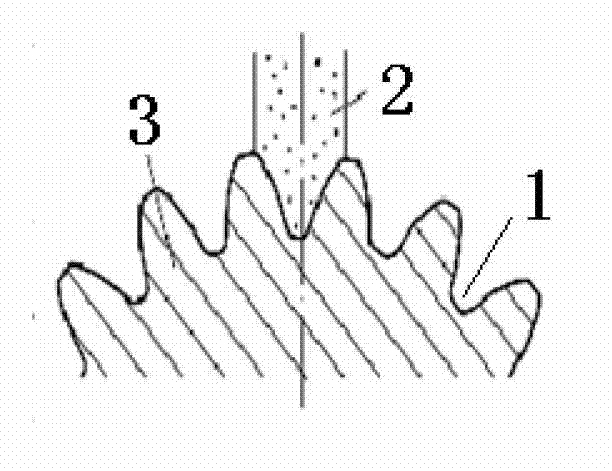

Method used

Image

Examples

Embodiment

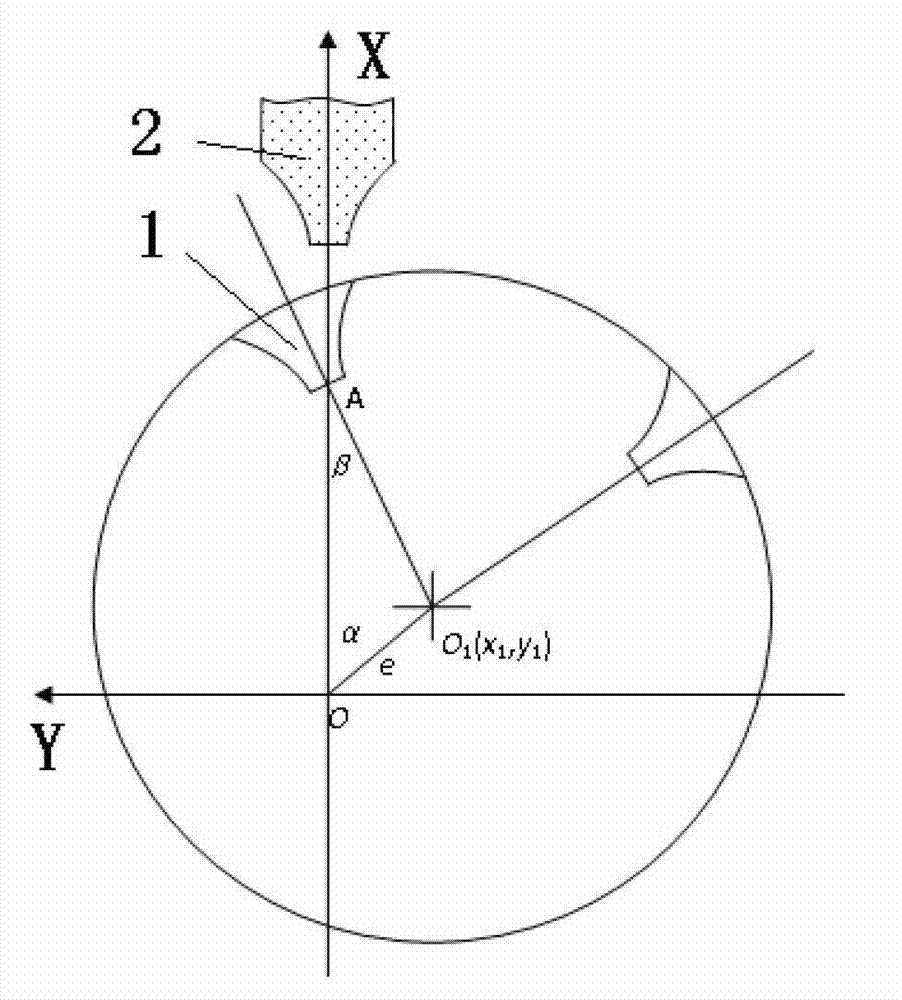

[0064] Taking the reference cogging as an example, the additional translation of the grinding wheel in the X-axis and Y-axis directions is represented by Δx and Δy respectively, then: Δx = e · sin ( α + β ) Δy = e · cos ( α + β ) , Using the above method, when the CNC form grinding wheel gear grinding machine grinds the involute tooth profile of the large gear, it does not need to install and align...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com