Mining anti-explosion diesel steel-wheel locomotive with drive system containing planet reducer

A planetary reducer and transmission system technology, which is applied to the transmission device with reciprocating piston internal combustion engine, etc., can solve the problems of unsuitable working environment of calcium carbide production plant and small transmission torque, and achieve the effect of compact structure, improved traction and stable transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

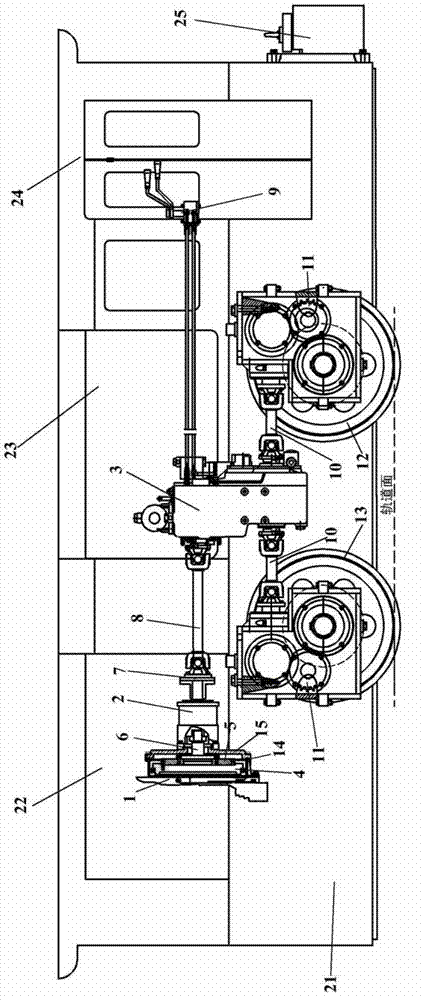

[0018] see Figure 1 ~ Figure 2 , the mining explosion-proof diesel engine steel-wheeled locomotive whose transmission system includes a planetary reducer, including a car body 21, on which a locomotive engine compartment 22, a locomotive transmission compartment 23 and a cab 24 are arranged; the cab 24 The lower end of the right end face of the locomotive is provided with a locomotive bumper 25; the locomotive engine compartment 22 is provided with a diesel engine 1; the locomotive transmission compartment 23 is provided with a hydraulic shift transmission 3; the diesel engine 1 and the hydraulic shifter The gear transmissions 3 are connected through the planetary reducer 2 and the input universal coupling 8 in turn;

[0019] The flywheel 4 of the diesel engine 1 is provided with a flywheel connection plate 5, the flywheel connection plate 5 is connected to the input shaft 6, and the input end of the planetary reducer 2 is connected to the flywheel connection plate 5 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com