One-step centering ship shafting mounting method

An installation method, a one-time technology, applied in ship components, ship construction, transportation and packaging, etc., can solve the problems of large shaft alignment tolerance, heavy workload, and large hull vibration, etc., and achieve the solution of large alignment tolerance , reduce the number of alignment installations, and ensure the effect of safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

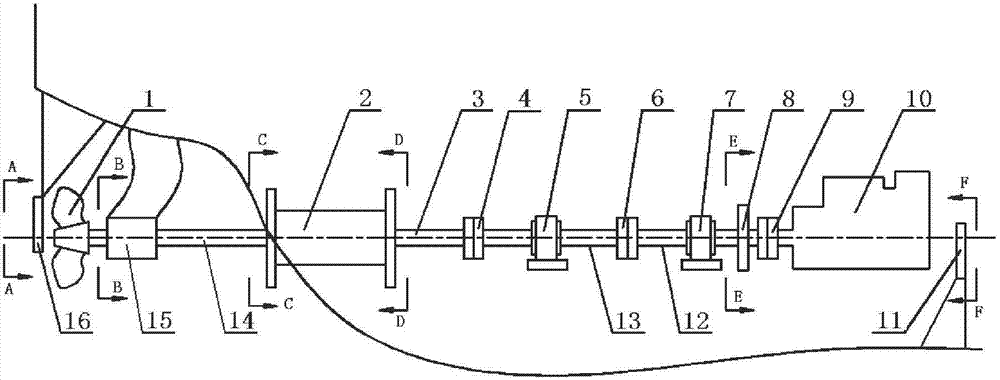

[0054] "Shafting and main engine installer" on a 750KW coastal tugboat

[0055] Positioning of rudder system, shaft system and main engine center line:

[0056] 1. Make the shaft sample rod, and check the correctness of the front and rear positions of the shaft system. Wherein, the distance between the rear end of the stern tube 2 and the front end of the stern tube 2 is 3984mm, and the distance between the rear end of the stern tube 2 and the center of the gearbox seat is 7349mm.

[0057] 2. Pulling wires and hanging wires (shafting pulling wires and rudder hanging wires are carried out at the same time).

[0058] 3. According to the upper and lower base points of the rudder system and the bow base point 11 and stern base point 16 (bow base point F23#, stern base point F-2#) of the rudder system determined by the hull profession, the diameter of the steel wire used for the suspension and stay wires is Φ0. 5mm, the hanging weight of the hanging wire is 0.5kg or more, and the...

Embodiment 2

[0107] 20-meter patrol boat "shafting and main engine installer"

[0108] The power plant of this boat adopts Chongqing Cummins NT855-M270 diesel engine and ZF305-2A gearbox. The shaft system is connected by a flange coupling, the main engine and the gear box are connected by an elastic coupling, and the shaft system adopts two-machine two-pulse linear transmission. The two shaft systems are symmetrically arranged, the length of the shaft system is about 4.890 meters, and the included angle with the baseline is about 7 degrees.

[0109] General rules:

[0110] The ship adopts wire drawing method for positioning and boring technology, and the shafting, main engine and gear box are aligned, installed and submitted for inspection on the berth.

[0111] 1 Shaft cable positioning

[0112] 1.1 Use the shafting sample stick to check whether the front and rear end faces of the shafting stern tube are correct, and make a record. Wherein, the distance between the rear end of the ste...

Embodiment 3

[0185] 618 Patrol Boat "Engine and Shafting Installer"

[0186] 1. Description:

[0187] This program is compiled according to the relevant drawings and documents of the 618BIII-10# ship issued by the design department of our company, in accordance with the construction procedures and combined with the specific conditions of our class, and is suitable for the shafting and main engine installation of the 618BIII-10# ship.

[0188] 2. Shafting and host positioning must meet the following conditions:

[0189] 2.1 Shaft alignment

[0190] 2.1.1 Conditions that must be met for optical centering of shafting:

[0191] 2.1.1.1 The assembly and welding work of the forward engine bulkhead and below the main deck to the aft structure has been completed, and the pyrotechnic calibration work has been completed.

[0192] 2.1.1.2 The tightness test of the above-mentioned areas including double bottom, after fresh water tank, cold storage, cabins connected to the hull in the engine room an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com