Process for preparing potassium chloride by using carnallite containing calcium sulfate

A carnallite, calcium sulfate technology, applied in the direction of alkali metal chloride, etc., can solve the problem of not producing potassium chloride, etc., and achieve the effects of easy filtration, simple production process and coarse particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

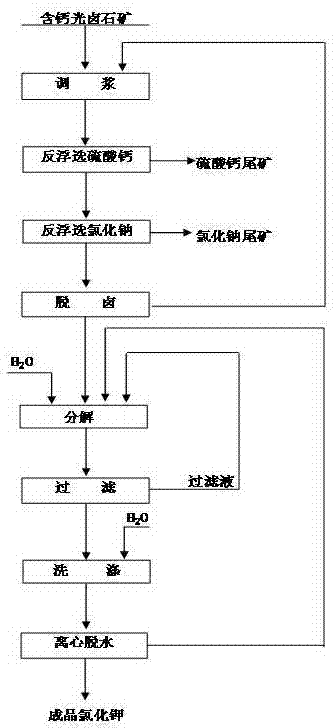

[0025] Embodiment 1, with reference to figure 1 , a kind of technique that utilizes calcium sulfate-containing carnallite ore to produce Potassium Chloride, its steps are as follows:

[0026] (1) The water-mined or dry-mined carnallite containing calcium sulfate mined in the salt field is firstly mixed with old brine, and a collector for flotation calcium sulfate is added during the slurry adjustment, and the material after the slurry adjustment is floated for the first time Selecting and collecting calcium sulfate;

[0027] (2) After the calcium sulfate is selected, the slurry is added to the collector for flotation of sodium chloride, and the sodium chloride is reverse flotation for the second time;

[0028] (3) Dehalogenate the product in the tank after selecting sodium chloride. After dehalogenation, the solid phase is decomposed by adding water. After decomposing, the solid phase is concentrated, filtered, washed, centrifugally dehydrated, and finally dried to obtain the...

Embodiment 2

[0029] Example 2, in the step (3) of the process for producing potassium chloride by utilizing calcium sulfate-containing carnallite ore described in Example 1: the liquid phase after dehalogenation returns to calcium sulfate flotation in step (1) The previous pulping operation is recycled; the liquid phase generated by filtration and centrifugal dehydration is returned to the decomposition operation for recycling.

Embodiment 3

[0030] Example 3, in the step (1) of the process for producing potassium chloride from carnallite ore containing calcium sulfate described in Example 1: the mass content of calcium sulfate in water mining or dry mining carnallite is not less than 2% .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com