Method for preparation of ceramsites by using sludge and river sediment and harmlessness treatment and immobilization of heavy metals

A technology for river sediment and heavy metals, applied in chemical instruments and methods, sludge treatment, water/sludge/sewage treatment, etc., can solve problems such as heavy metal solidification, and achieve good compactness, low water absorption, and high strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

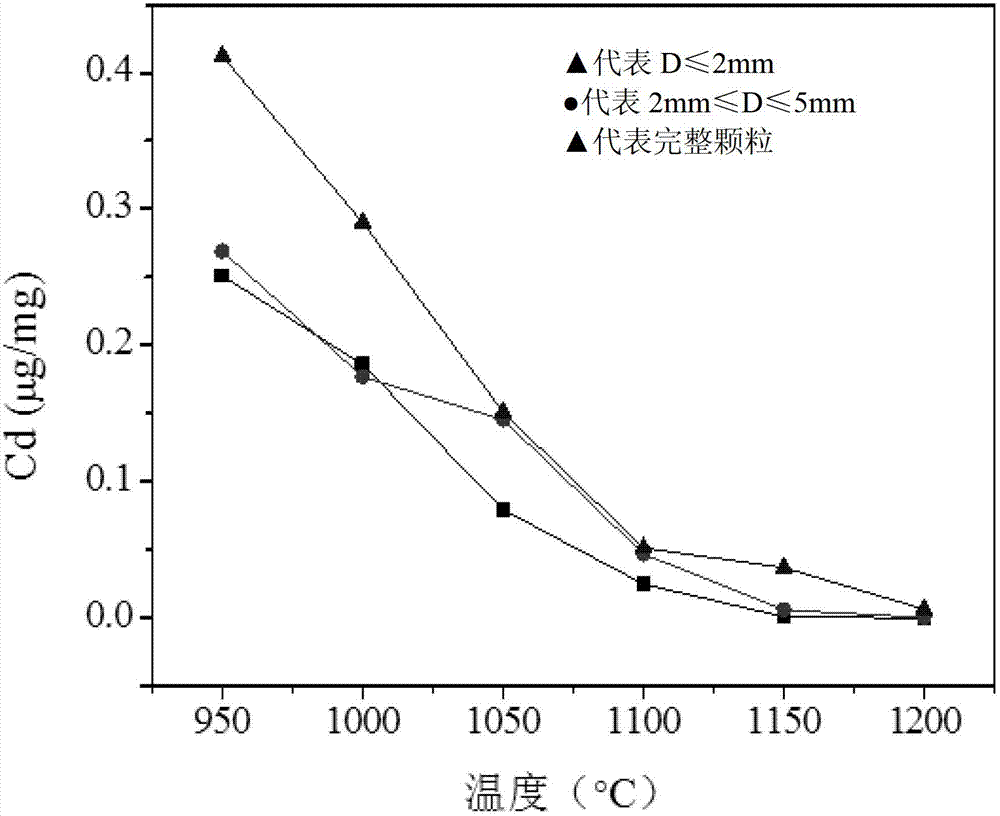

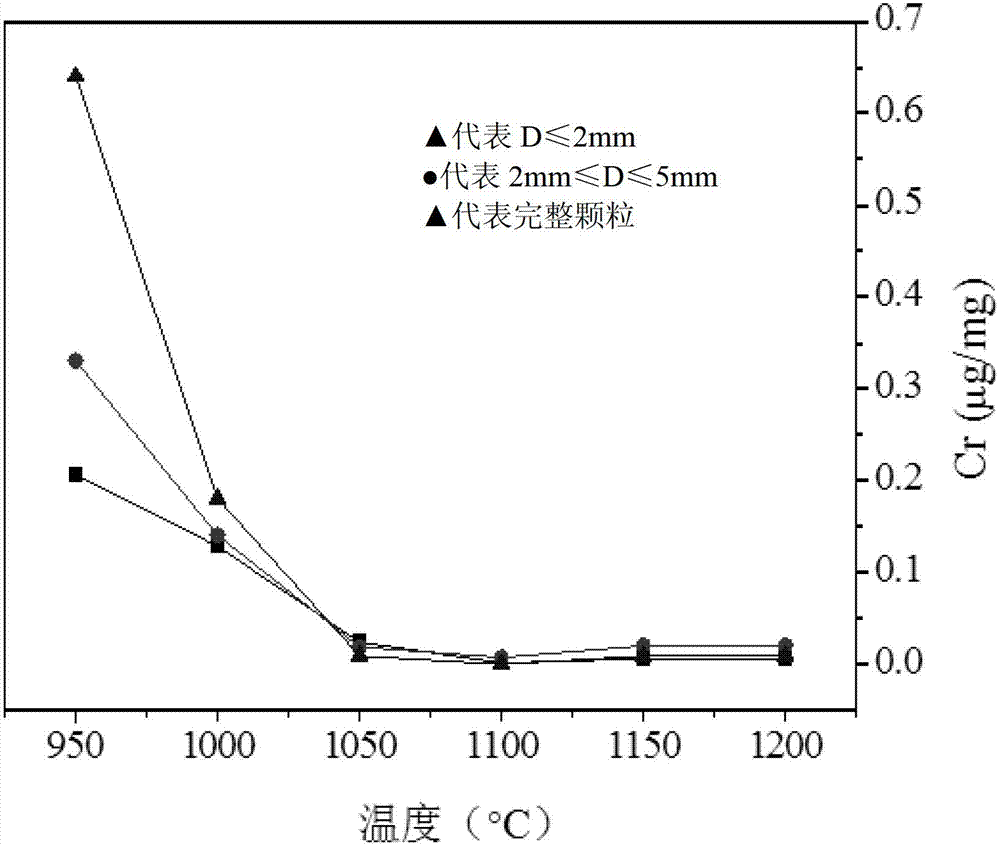

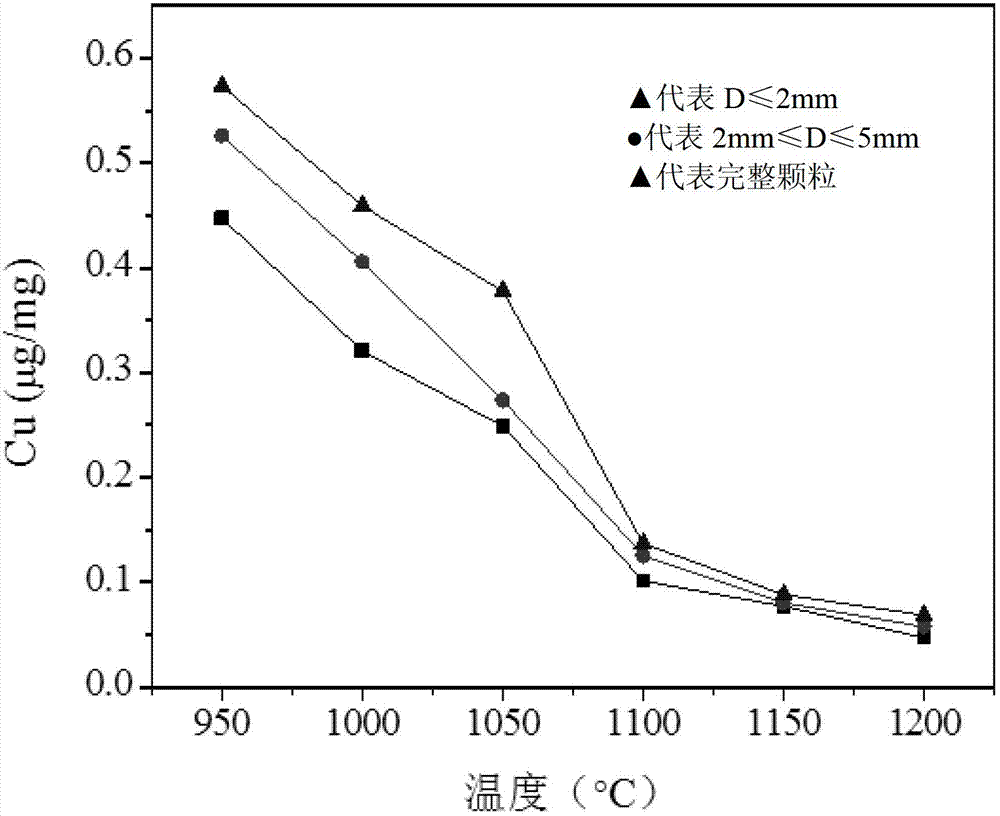

[0017] Embodiment 1: In this embodiment, a method of using sludge and river bottom mud to prepare building ceramsite is carried out according to the following steps: the sewage sludge and river bottom mud are naturally dried until the water content drops to 25%~35% after crushing, the crushed sewage sludge and river sediment are mixed according to the mass ratio of 3: (1~8) to obtain a mixture, and then silicate substances are added, and the amount of silicate substances It is 5%~15% of the mass of the mixture, mixed evenly, and then placed in a granulator for extrusion molding to obtain a ceramsite embryo body with a particle size of 6~10mm, dried naturally, and heated at a rate of 8~10 ℃ / min. Then keep it at 1050-1150°C for 20-40 minutes, and cool down with the furnace; the ceramsite for construction is obtained.

[0018] After testing, the loose bulk density of ceramsite samples after firing is 650~800 kg / m 3 , the apparent density is 1500~1800 kg / m 3 , the mud content ra...

specific Embodiment approach 2

[0026] Embodiment 2: This embodiment is different from Embodiment 1 in that: the silicate substance is sodium silicate. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0027] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the mass ratio of crushed sewage sludge to river bottom mud is 3: (3~7). Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com