Medium inoculation technology and its special equipment in Cordyceps cicadae solid fermentation industry

A technology of solid fermentation and special equipment, applied in the inoculation, mixing line, sterilization, culture medium inoculation process and its special equipment, cooling, wheat cooking fields, can solve the problem of labor-intensive, polluted bacterial liquid, easy to contaminate bacteria and other problems, to achieve the effect of reducing heavy physical labor, good mobility, and sufficient and uniform bacterial liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

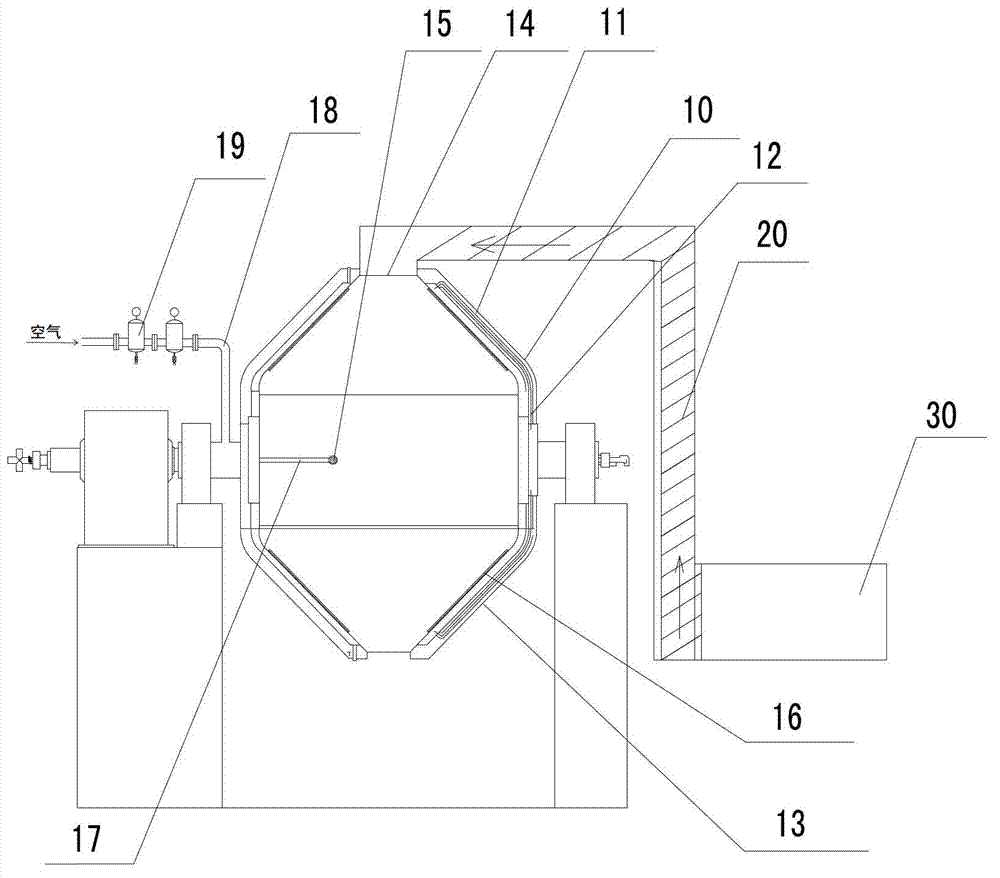

[0032] The technical scheme of the present invention will be further described below in conjunction with the drawings and specific embodiments.

[0033] The specific steps of the culture medium inoculation process in the cicada flower solid fermentation industry of the present invention are as follows:

[0034] 1. Put the wheat in a wheat washing machine to clean it;

[0035] 2. Transport the cleaned wheat to the top of the integrated tank through the lifting equipment, and enter the inside of the integrated tank through the wheat inlet on the top of the integrated tank, and cook and sterilize for 45 minutes at 121°C;

[0036] 3. Cool the wheat to 30℃ with sterile air and the cooling equipment of the integrated tank, pass the bacteria liquid into the integrated tank, and rotate the integrated tank around the axis to mix the wheat and the bacteria liquid thoroughly.

[0037] The rotation speed of the integrated tank body is 2.8 revolutions per minute, the heat transfer area is 13 square ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com