Structure for repairing urban bituminous pavements and construction method thereof

A technology for asphalt pavement and structure repair, applied to roads, roads, on-site paved coagulation pavements, etc., can solve problems such as roadbed pollution, urban environmental impact, waste of resources, etc., to improve anti-deformation ability and reduce unevenness Settling, avoiding the effect of cross-influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

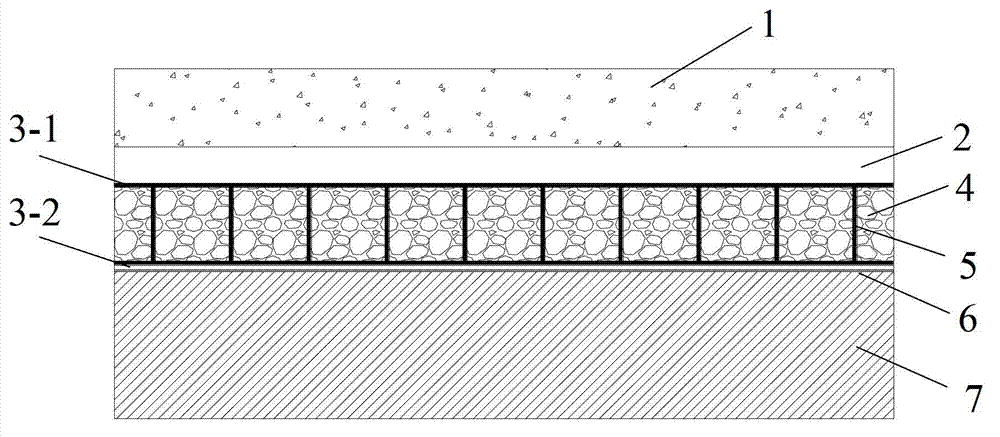

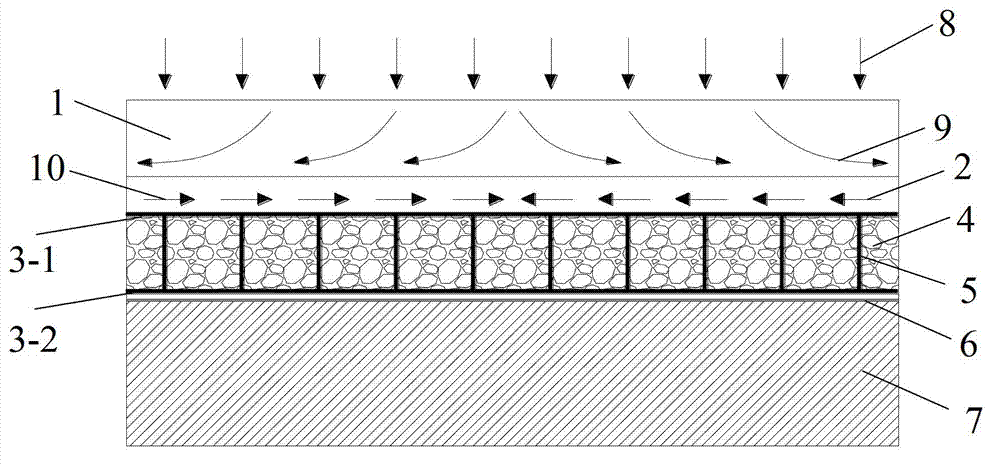

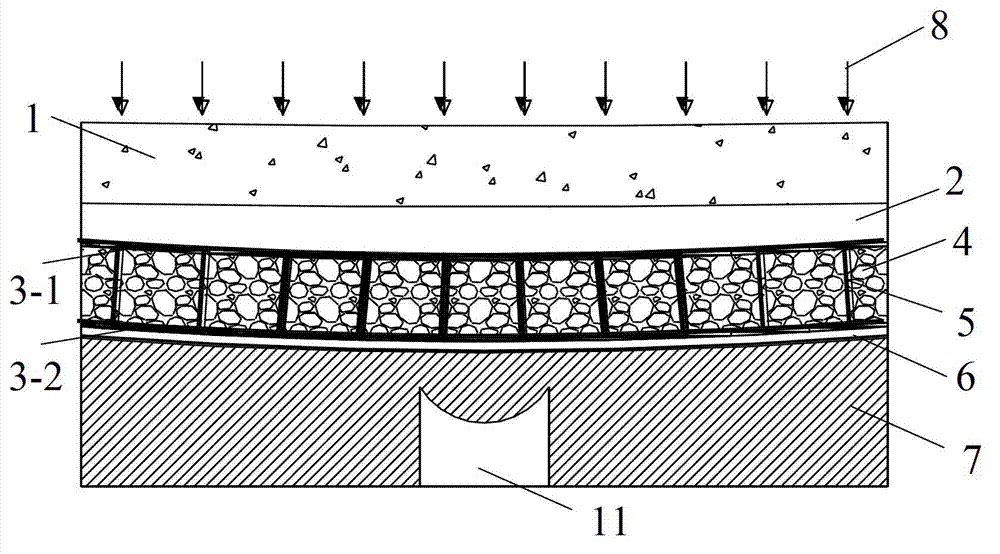

[0043] see figure 1 , an urban asphalt pavement repair structure, comprising from top to bottom an asphalt pavement surface layer 1, a base layer 2, an upper high-strength geogrid 3-1, a geocell 5 filled with old asphalt pavement mixed aggregate 4, a reinforcement layer, The lower high-strength geogrid 3-2, the waterproof layer 6 and the subgrade 7.

[0044] The base 2 is a cement-stabilized gravel layer in a semi-rigid base.

[0045] When the elongation is 0.5%, the tensile strengths of the upper high-strength geogrid 3-1 and the lower high-strength geogrid 3-2 are both 160kN / m.

[0046] The old asphalt pavement mixed aggregate 4 is formed by mixing gravel aggregates with a proportion of 20% of the old asphalt pavement aggregate mass into the old asphalt pavement aggregate obtained after crushing the broken pieces of the old asphalt pavement, Wherein, the maximum particle size of the old asphalt pavement aggregate obtained after crushing treatment is less than 50 mm.

[00...

Embodiment 2

[0063] The urban asphalt pavement repair structure of Example 1 is applied to a certain urban asphalt pavement repair project. The asphalt pavement of a 45m section of the road is severely damaged and needs to be repaired. When the asphalt pavement is repaired, the left side of the road adopts the repair structure and construction method of embodiment 1, and the right side of the road adopts the prior art of renovation method, that is, on the basis of the method of the present invention, the upper layer of high-strength geogrid, geocell, and lower layer are removed. High-strength geogrid and waterproofing layer. After the pavement repair project is completed, the static pressure creep test of the bearing plate is carried out at the left and right centerlines of the road respectively, and the bearing plate is 1.0m 2 square plate with a load of 300kPa. After 100 hours of static pressure, the creep amount of the left road pavement using the method of the present invention is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com