Simple reinforcing method of vacuum electroosmosis combined prepressing soft soil foundation

A combined preloading and soft soil foundation technology, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of short effective vacuum preloading time, low soft soil strength, and long construction period, so as to shorten the construction period, The effect of reducing the consolidation time and improving the reinforcement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

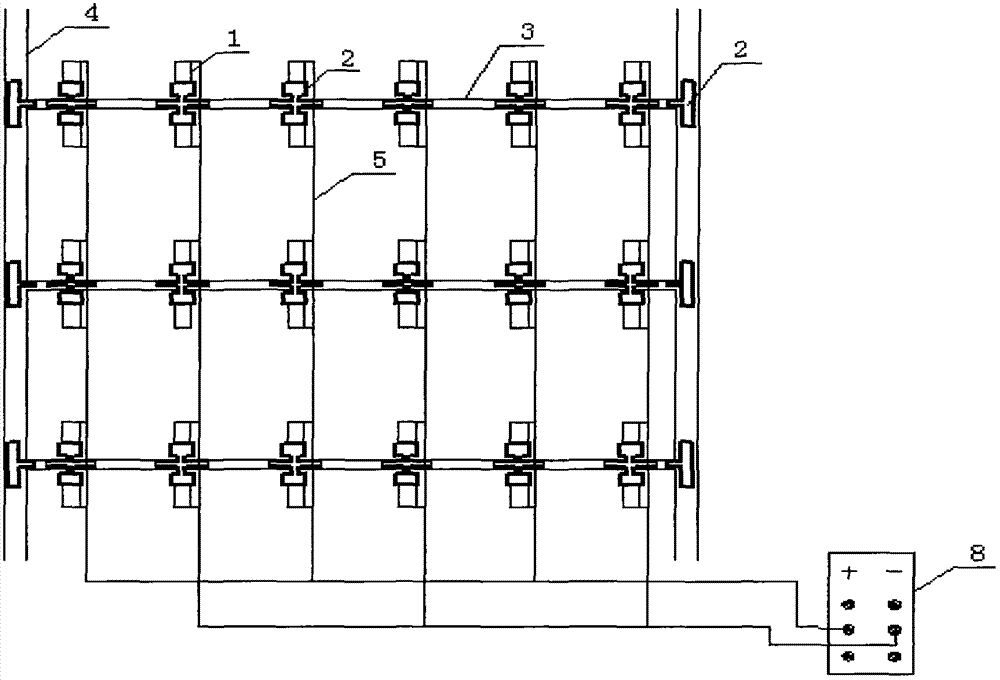

[0016] 1. The vacuum preloading method is used for the first reinforcement treatment of the soft soil site

[0017] 1) The site is leveled by machinery, and the levelness reaches 5‰.

[0018] 2) Lay a layer of woven fabric; if dealing with ultra-soft ground, you can lay out 300-400g geotextile. The foam wrapped by the filter membrane is used as an artificial enclosure.

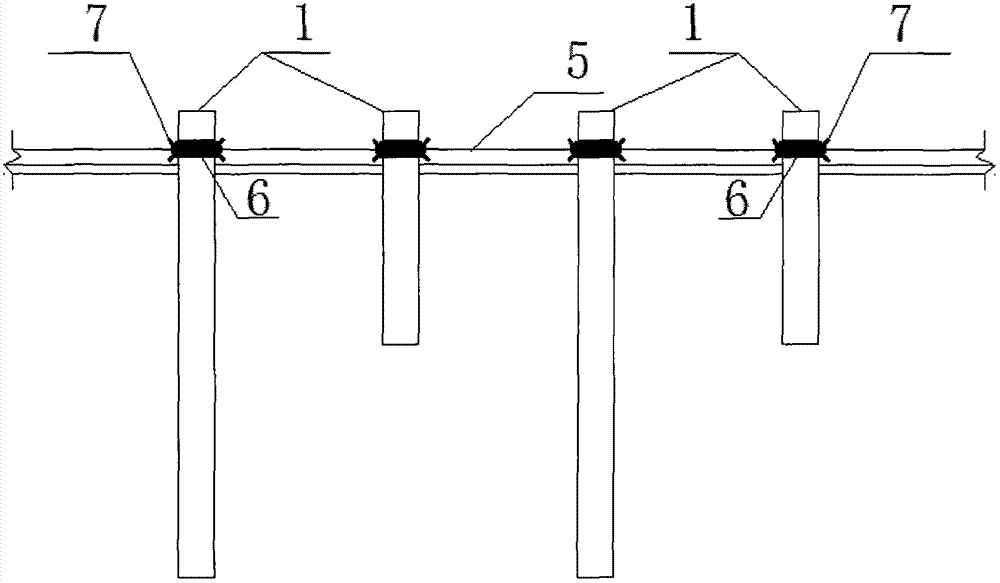

[0019] 3) Carry out the construction of the new vertical drainage board (1), and calculate and determine the spacing, depth and specification of the new vertical drainage board (1) with alternate lengths and shorts according to the geological conditions. The hole diameter of the drainage board is generally 80-120 μm, and the larger hole diameter can be selected appropriately. The exposed length of the drainage board is determined according to the spacing, generally 40-60 cm, and the width of the carbon fiber cloth is 20-30 cm. Smooth and aligned, no mud entering.

[0020] 4) The setting of the horizontal dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com