Solar generating heat-collecting system high in photoelectric or photothermal conversion efficiency

A technology of solar heat collecting tubes and solar cells, which is applied in the field of solar concentrated heat collection and power generation, which can solve the problems of single solar power generation or heating equipment, no constant temperature control of solar cells, and the decline of solar cell power generation efficiency, and achieve good structural strength , High photothermal conversion efficiency, high photoelectric or photothermal conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

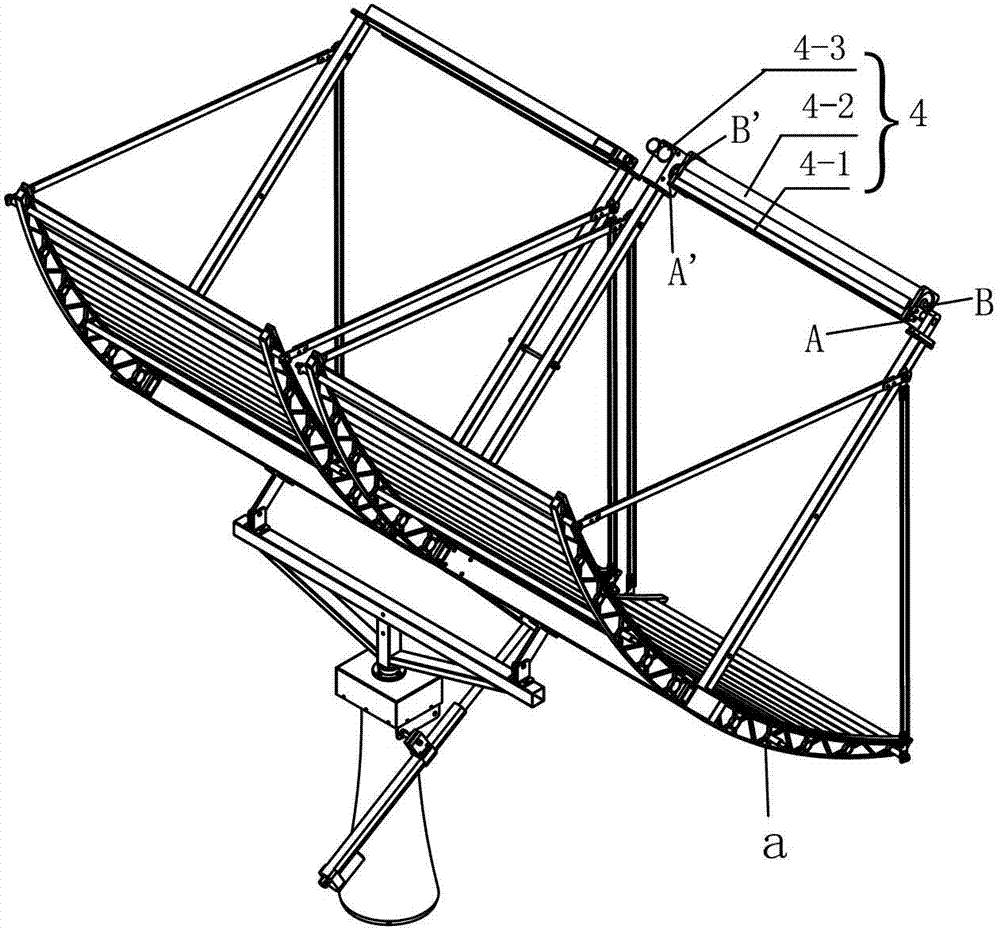

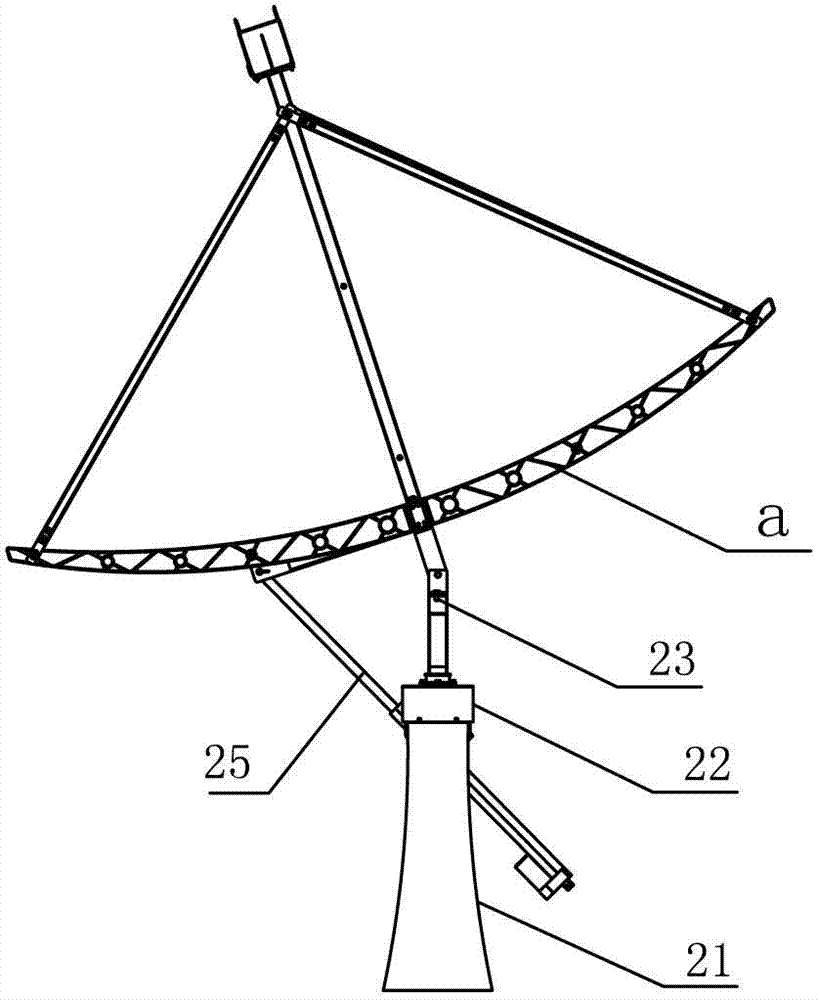

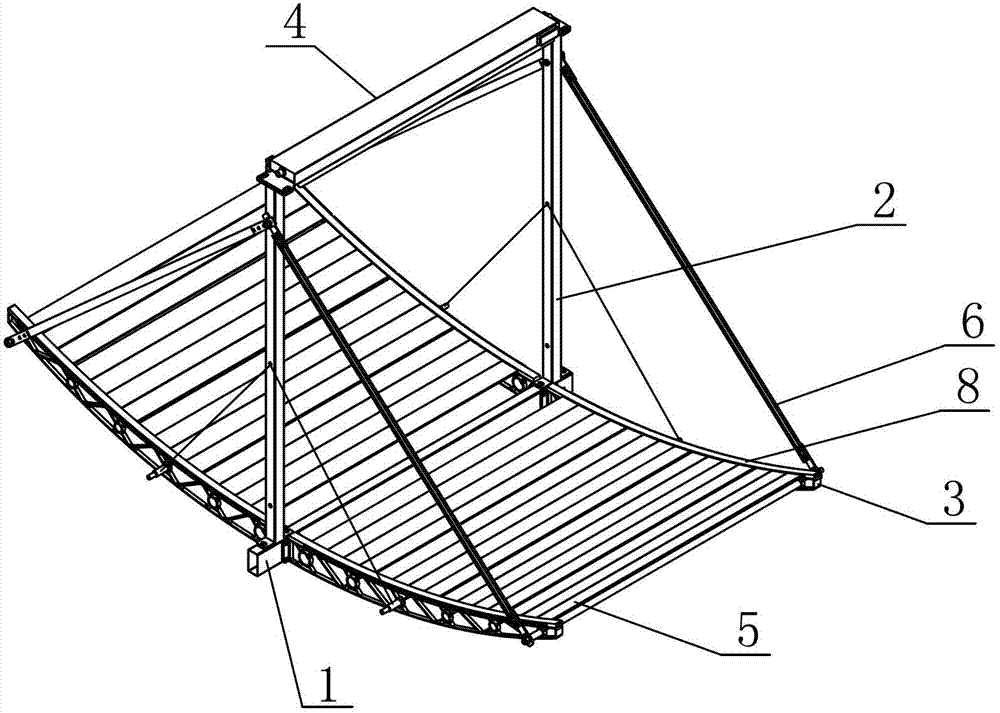

[0028] Such as figure 1 -10. The solar power generation and heat collection system of this embodiment includes: a concentrator a for parallel superimposition of light rays and a parallel light receiver 4 arranged adjacent to the concentrating belt of the concentrator a; the parallel light receiver 4 includes: The solar cell 4-1 and the solar heat collecting tube 4-2 that are set back to one body; when solar power is needed, the solar cell 4-1 of the parallel light receiver 4 is opposite to the reflective surface of the concentrator a; when a liquid heat source is needed , flip the parallel light receiver 4 so that the solar heat collecting tube 4-2 is opposite to the reflective surface of the concentrator a. In other implementation manners, the parallel light receiver 4 can adopt a single solar cell or a solar heat collecting tube.

[0029] The solar cell 4-1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com