High-power LED (Light Emitting Diode) bracket and high-power LED packaging structure

A technology of LED bracket and LED packaging, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of high cost and high cost LEDs being introduced to the market, and achieve low cost, high ultraviolet light shielding, and high heat resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

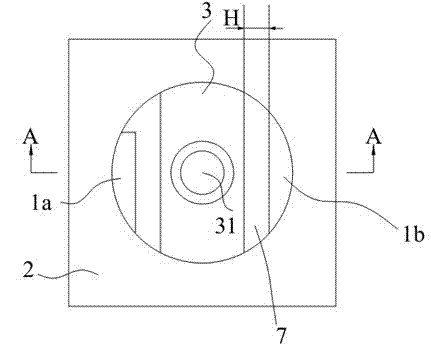

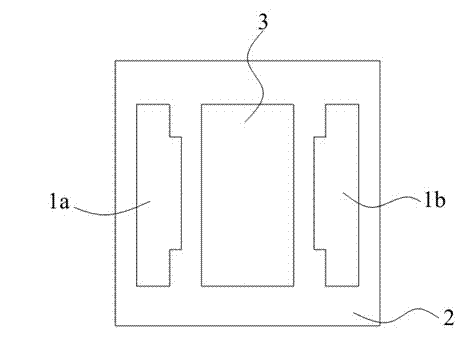

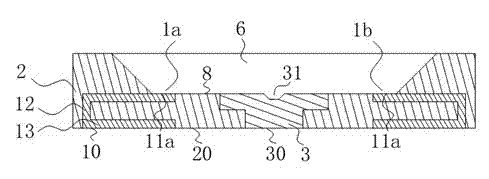

[0032] Such as figure 1 , 2 , 3, the present invention discloses a high-power LED bracket, including conductive feet 1a, 1b and a base 2 that wraps the conductive feet 1a, 1b, and a concave cavity 6 is formed on the top of the base 2, so A heat sink 3 is fixed at the bottom of the concave cavity 6, and the base 2 is made of high temperature resistant material. The high temperature resistant material is mainly liquid crystal polymer and contains a plurality of filler particles.

[0033] During the preparation of the molding material, the filler particles are uniformly kneaded into the liquid crystal polymer. Preferably, the greater number of filler particles near the outer surface of the material can be achieved by known mixing and molding methods.

[0034] Because liquid crystal polymers only need hydroxybenzoic acid, acid anhydride, biphenol, and terephthalic acid to melt and polymerize, the heat resistance can reach above 410°C, but its color is slightly yellow. Because a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com