Oblique edge sheet shearer with thick wave shape edge

A shearing machine and oblique blade technology, which is applied to shearing equipment, shearing devices, knives for shearing devices, etc., can solve problems such as low efficiency, unsuitability for mass production, and inability to achieve thick corrugated edge plate shearing, etc. problem, to achieve the effect of low noise, simple structure and reduced shear force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

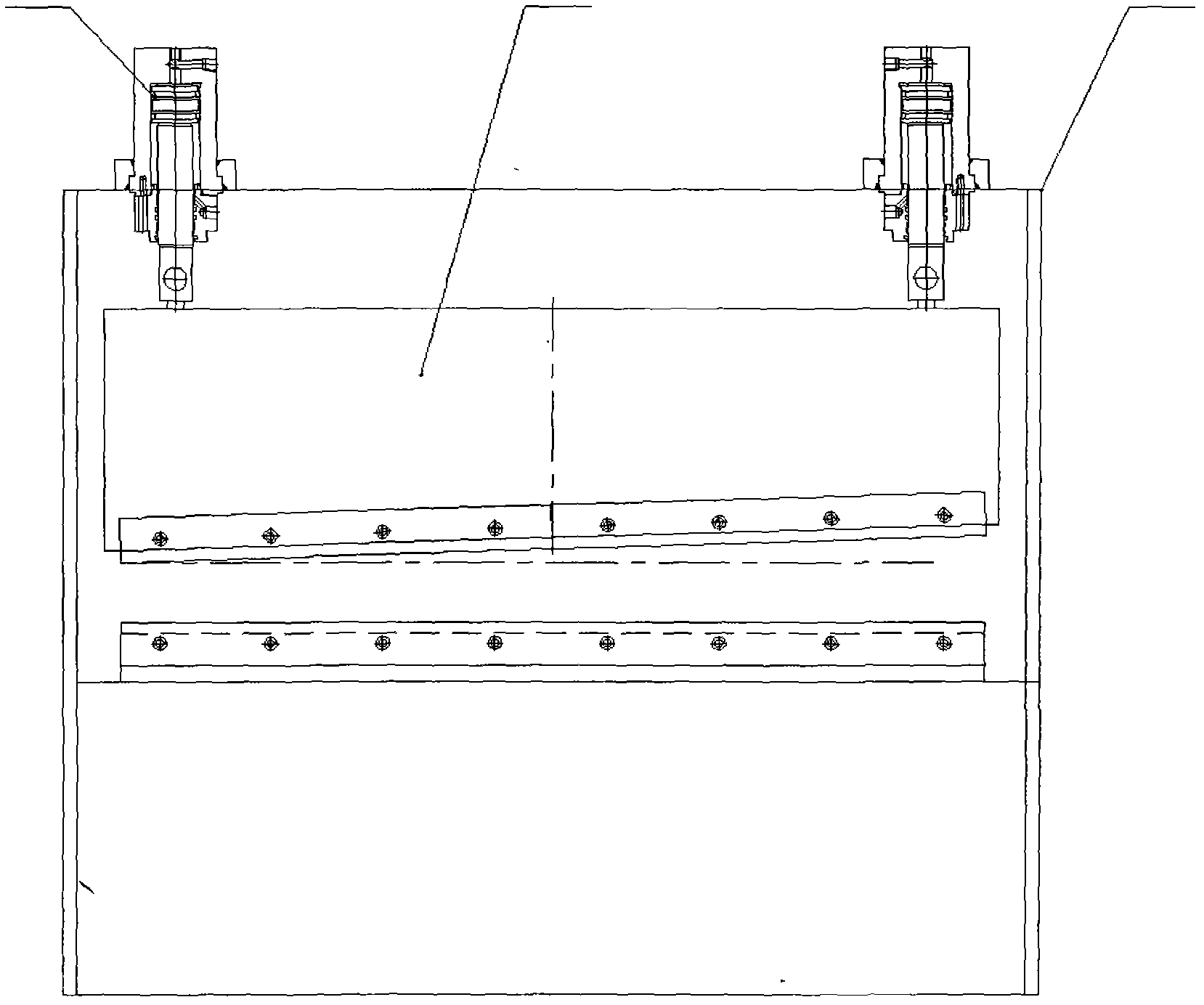

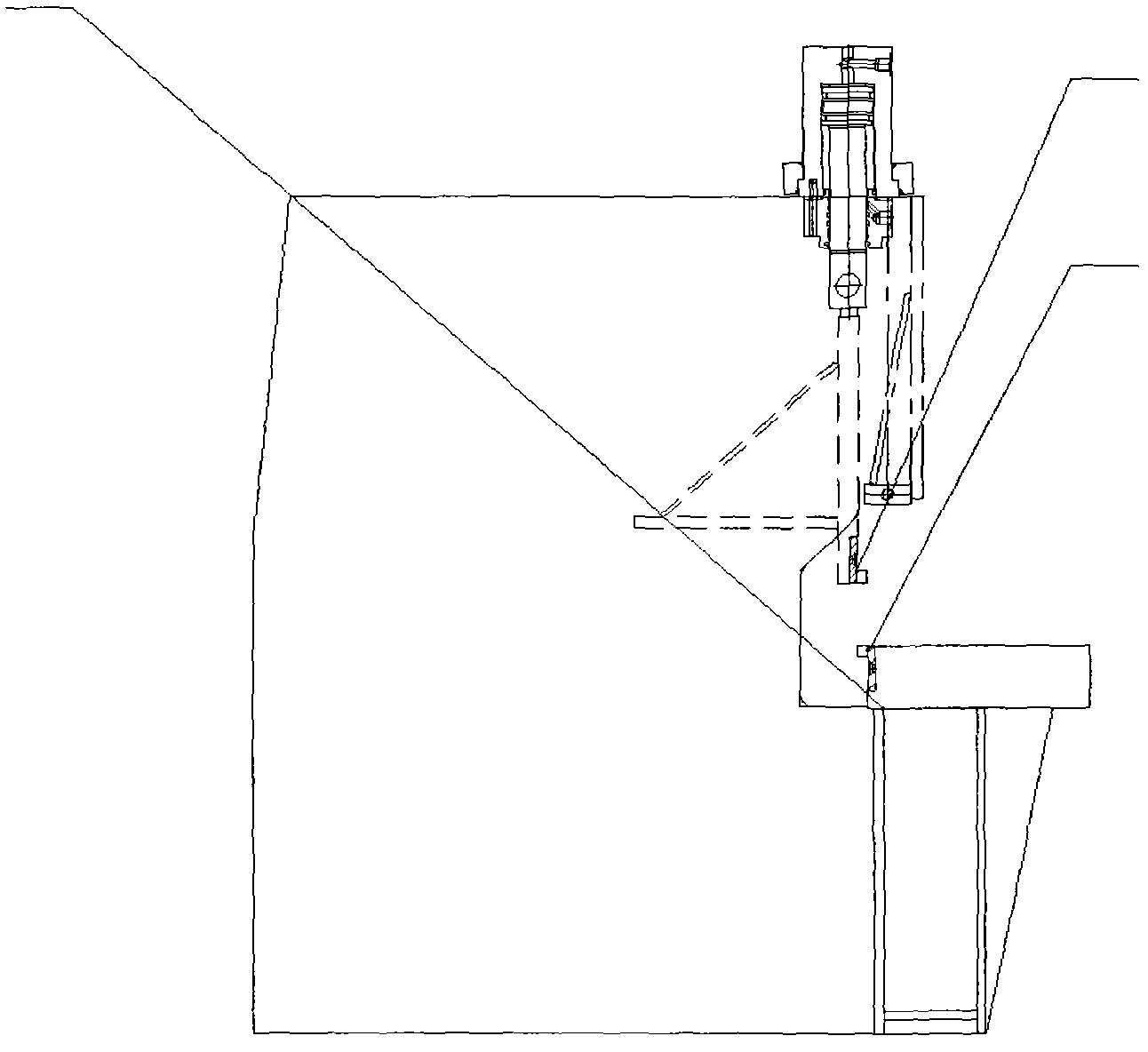

[0017] See attached figure 1 , figure 2 , a kind of plate shearing machine with thick corrugated edge and oblique blade, which consists of serial hydraulic cylinder (1), tool holder (2), frame (3), workbench (4), oblique blade waveform upper knife (5), flat blade waveform Lower knife (6) forms. The oblique edge waveform upper knife (5) and the flat edge waveform lower knife (6) are designed and shaped according to the shape of the workpiece (see attached image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 ). The upper knife (5) with an oblique edge waveform is tightly connected with the knife holder (2), and the lower knife (6) with a flat edge waveform is tightly connected with the workbench (4). Under the action of hydraulic power, the series hydraulic cylinder (1) pushes the tool holder (2) to move up and down, the tool holder (2) moves downward, and the oblique blade waveform upper knife (5) is gradually combined with the flat blade waveform lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com