Welding gun contact tube

A technology of contact tip and contact tip holder, which is applied in the direction of electrode accessories and welding rod characteristics, can solve the problems of insufficient heat dissipation area, failure to achieve heat dissipation effect, high burning rate of contact tip, etc., and achieve increased conductivity, conductivity and heat dissipation The effect of excellent effect and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

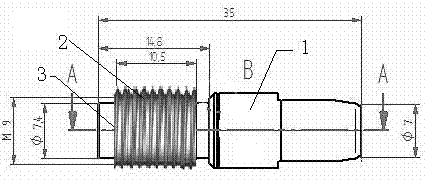

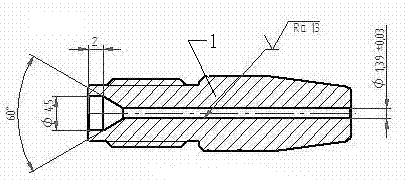

[0011] Such as Figure 1-2 Shown is a welding torch contact tip, including a contact tip body 1, the tail of the contact tip body 1 is provided with an external thread 2 that matches the threaded hole of the contact tip seat on the head of the welding torch; the external thread 2 is an M9 elongated thread ; The length of the contact tip body 1 is set to be 35 mm longer; the tail of the contact tip body is a threaded connection part 3, and the threaded connection part 3 is set to be 14.8 mm longer.

[0012] The contact tip of the welding torch provided by the present invention has a longer body than the common contact tip, and the length of the threaded part is increased, so that the part where the contact tip is connected to the welding torch is lengthened, so that the conductive contact surface is increased by 1 / 3 compared with the prior art , which increases the cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com