Ring piece machining system and method as well as ring piece moving-out device

A processing method and processing system technology, applied in the direction of metal processing, manufacturing tools, and other manufacturing equipment/tools, can solve problems such as low production efficiency, poor working conditions, and potential safety hazards, and achieve high production efficiency, convenient operation, and reduced The effect of human cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

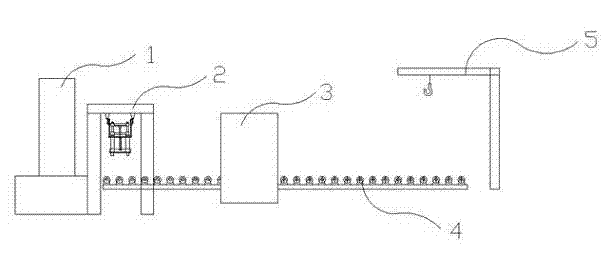

[0045] A method for processing a large ring, the steps of which are:

[0046] A): The heated billet is upsetting and punching on the press;

[0047] B): The billet is sent to the ring rolling machine 1 for ring rolling processing, and the billet is rolled to the required ring size according to the preset ring rolling control program, and the material is sent to the ring unloading device 2 after the rolling is completed Signal;

[0048] C): The ring piece unloading device 2 sends the ring piece to the conveying roller table 4 according to PLC program control, and then sends a running signal to the conveying roller table 4;

[0049] D): The thermal printer 3 is installed at the end of the conveying roller table 4, and the ring is transported by the conveying roller table 4 to the front of the thermal printer 3, and the thermal printer 3 automatically completes a printing cycle according to the PLC control program;

[0050] E): The rings after printing are stacked by the cantil...

Embodiment 2

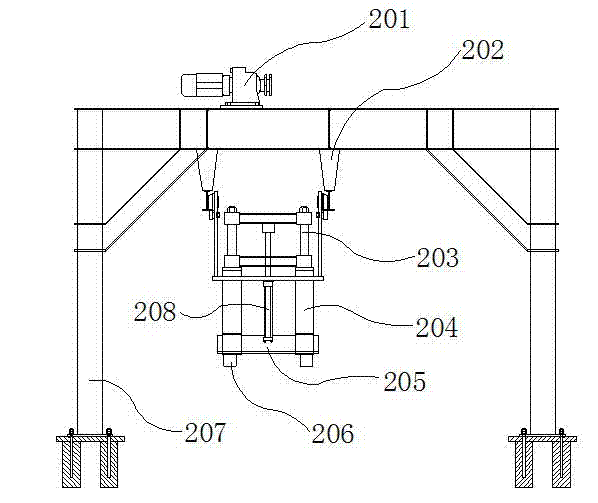

[0058] With embodiment 1, the difference is that one end of the hydraulic cylinder 208 is connected with the lower connecting rod 205 at the bottom end of the telescopic rod 203; Figure 5 As shown, the number of rollers 206 can be two. The motor 201 drives the movement of the control device through chain transmission. Then, the same as in Embodiment 1, the hydraulic cylinder 208 drives the telescopic rod 203, the upper link and the roller 206 to move up and down. The expansion and contraction of the hydraulic cylinder 208 drives the roller 206 to move up and down. When the roller 206 reaches the center of the ring, the hydraulic cylinder 208 is extended, and the telescopic rod 203, the upper link, the lower link 205 and the roller 206 are all downward. movement, the roller 206 is inserted into the ring, and the motor 201 is started at this time, and the motor 201 drives the movement of the control device, thereby achieving the effect of moving the ring from the ring rolling ...

Embodiment 3

[0060] Same as embodiment 1, the difference is that the number of rollers 206 can be five.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com