Production process method for cortisone crude product

A production process, cortisone technology, applied in the production process field of crude pine products, can solve the problems of low yield, achieve the effect of product yield and quality improvement, and good compatibility of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

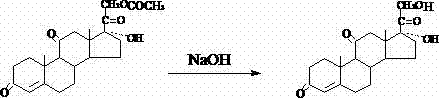

Image

Examples

Embodiment 1

[0013] Throw in 600ml of methanol, 450ml of chloroform, add 100g of cortisone acetate, stir to dissolve, after the solution is clear, cool down to -2°C to 0°C, add 5g of potassium hydroxide to 100ml of methanol solution to make a catalyst, and control the temperature at 0±2°C, after adding the potassium hydroxide-methanol solution, start to stand still and count, react for 40 minutes, the temperature is 0±2°C, use glacial acetic acid to neutralize the system to neutral, concentrate under reduced pressure, cool down to 0-10°C, filter, After drying, 83 g of cortisone crude product was obtained, the yield was 83%, and the content determined by ultraviolet spectrophotometry was 97.9%.

Embodiment 2

[0015] Throw in 600ml of methanol, 450ml of chloroform, add 100g of cortisone acetate, stir to dissolve, after the solution is clear, cool down to -2°C to 0°C, add 6g of potassium hydroxide to 100ml of methanol solution to make a catalyst, and control the temperature at 0±2°C, after adding the potassium hydroxide-methanol solution, start to stand still and count, react for 40 minutes, the temperature is 0±2°C, use glacial acetic acid to neutralize the system to neutral, concentrate under reduced pressure, cool down to 0-10°C, filter, After drying, 84 g of cortisone crude product was obtained, the yield was 84%, and the content determined by ultraviolet spectrophotometry was 98.2%.

Embodiment 3

[0017] Throw in 600ml of methanol, 450ml of chloroform, add 100g of cortisone acetate, stir to dissolve, after the solution is clear, cool down to -2°C to 0°C, add 6g of potassium hydroxide to 100ml of methanol solution to make a catalyst, and control the temperature at 0±2°C, after adding the potassium hydroxide-methanol solution, start to stand still and count, react for 40 minutes, the temperature is 0±2°C, use glacial acetic acid to neutralize the system to neutral, concentrate under reduced pressure, cool down to 0-10°C, filter, Drying, cortisone crude product 83.5g, yield 83.5%, ultraviolet spectrophotometric determination content 98.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com