Wave-absorbing adhesive, preparation method thereof and wave-absorbing material

A technology of wave absorbing materials and adhesives, applied in the field of wave absorbing materials, can solve the problems of inability to meet structural wave absorbing materials, unable to achieve wave absorbing effect, and high brittleness of adhesive, and achieve good radar wave absorption function and good system. mutual solubility, the effect of improving toughness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

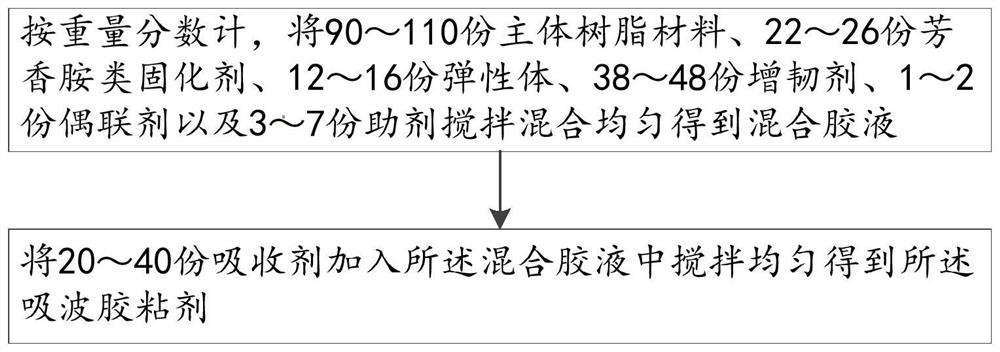

[0027] Such as figure 1 As shown, a method for preparing a wave-absorbing adhesive according to a preferred embodiment of the present invention is specifically illustrated. Such as figure 1 Shown, the preparation method of described wave-absorbing adhesive comprises the following steps:

[0028] S1. Stir and mix the main resin material, aromatic amine curing agent, elastomer, toughening agent, coupling agent and auxiliary agent evenly to obtain a mixed glue; and

[0029] S2. Add an absorbent to the mixed glue, stir and mix evenly to obtain the wave-absorbing adhesive.

[0030] It is worth mentioning that in the step S1, 90-110 parts of main resin material, 22-26 parts of aromatic amine curing agent, 12-16 parts of elastomer, 38-48 parts of toughening agent, 1-2 parts of coupling agent and 3-7 parts of auxiliary agent are stirred and mixed evenly to obtain the mixed glue.

[0031] In addition, it is also worth mentioning that in the step S2, 20-40 parts of absorbent are add...

Embodiment 1

[0051] This embodiment provides a microwave-absorbing adhesive, which is prepared according to the following steps:

[0052] First, by weight fraction, 100 parts of epoxy resin, 24 parts of diaminodiphenyl sulfone, 14 parts of isoprene rubber, 40 parts of modified polystyrene materials, 1 part of silane coupling agent, 5 parts of auxiliary agents and 1 part Part of ethanol was stirred at 2500r / min for 10min to obtain a mixed glue; secondly, 30 parts of carbonyl iron powder was added to the mixed glue, and stirred at 2500r / min for 10min to obtain the wave-absorbing adhesive.

Embodiment 2

[0054] This embodiment provides a microwave-absorbing adhesive, which is prepared according to the following steps:

[0055] First, by weight fraction, 90 parts of epoxy resin, 22 parts of diaminodiphenyl sulfone, 12 parts of isoprene rubber, 38 parts of modified polystyrene materials, 1 part of silane coupling agent, 3 parts of auxiliary agents and 0.9 One part of ethanol was stirred at 2500r / min for 10min to obtain a mixed glue; secondly, 20 parts of carbonyl iron powder was added to the mixed glue and stirred at 2500r / min for 10min to obtain the wave-absorbing adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com