Environment-friendly water-based flicking type metal car refinishing paint and preparing method thereof

A water-based technology for automotive refinish paint, applied in coatings, polyester coatings, etc., can solve problems such as unstable storage and coarsening, and achieve high sparkle, low VOC emissions, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

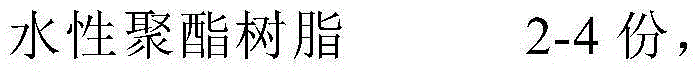

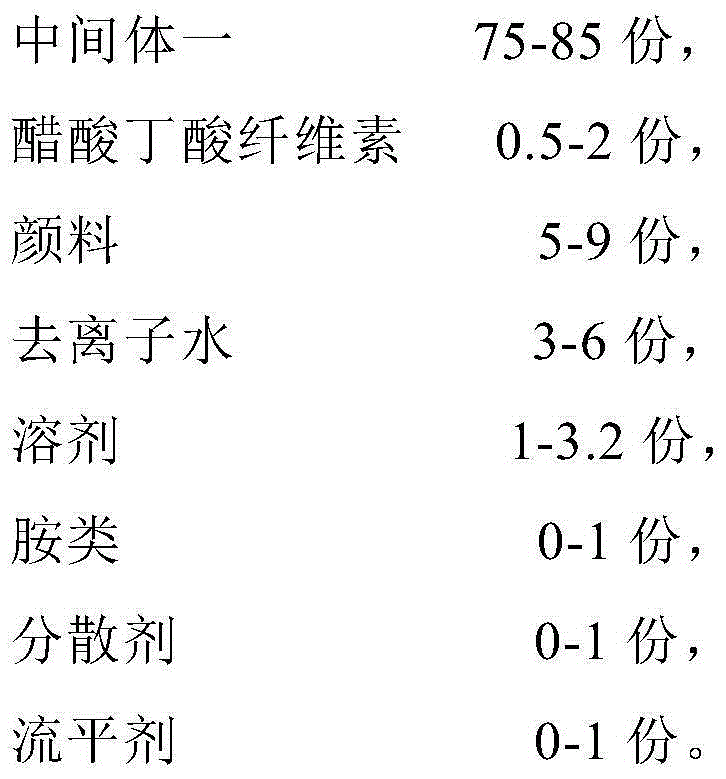

Method used

Image

Examples

Embodiment 1

[0029] (1) Weigh 68g of deionized water, 14g of ethylene glycol butyl ether, 6g of n-butanol, 2.3g of BYK192.3g, 0.7g of N-N dimethylethanolamine, and 10.8g of bentonite AEROSILR9771 into the reaction kettle, and stir for 25min under the mixer at 1200rpm To uniformity, intermediate 2 was obtained;

[0030] (2) Weigh 2.1g of diethylene glycol ether, 2.5g of FX1010 and mix and stir to form a mixture 1. While stirring, add the above-mentioned mixture 1, 62g of deionized water, and 6.4g of N-N dimethylethanolamine into the reaction kettle to form Mixture 2, then slowly add this mixture 2 into a reaction kettle filled with 126g of water-based polyester resin to form mixture 3, then weigh 10.8g of intermediate 2 and 0.23g of defoamer and put them into mixture 3 in turn according to the dosage of the formula In the middle, use a high-speed disperser to stir and disperse for 45 minutes at 1200 rpm to form intermediate one.

[0031] (3) Weigh 3.4g of diethylene glycol ether, 9.7g of d...

Embodiment 2

[0040] (1) Weigh 64g of deionized water, 18g of ethylene glycol butyl ether, 7g of n-butanol, 2.1g of BYK192.1g, 0.8g of N-N dimethylethanolamine, and 10.2g of bentonite AEROSILR97710.2g into the reaction kettle, and stir for 30min under the mixer at 1200rpm To uniformity, intermediate 2 was obtained;

[0041] (2) Weigh 2.2g of diethylene glycol ether, 2.3g of FX1010 and mix and stir to form a mixture 1. While stirring, add the above-mentioned mixture 1, 58g of deionized water, and 6.2g of N-N dimethylethanolamine into the reaction kettle to form Mixture 2, then slowly add this mixture 2 into a reaction kettle filled with 121g of water-based polyester resin to form mixture 3, then weigh 10.2g of intermediate 2 and 0.25g of defoamer and put them into mixture 3 in turn according to the dosage of the formula In the middle, use a high-speed disperser to stir and disperse for 40 minutes at 1200 rpm to form intermediate one.

[0042] (3) Weigh 3.2g of diethylene glycol ether, 10.1g...

Embodiment 3

[0047] (1) Weigh 60g of deionized water, 17g of ethylene glycol butyl ether, 4.5g of n-butanol, 1.88g of BYK1921.88g, 0.96g of N-N dimethylethanolamine, and 9779.75g of bentonite AEROSILR9779.75g into the reaction kettle, and stir under the mixer at 1200rpm 28min to uniformity, intermediate 2 was obtained;

[0048] (2) Weigh 1.9g of diethylene glycol ether and 1.86g of FX10101.86g and mix and stir to form a mixture 1. While stirring, add the above-mentioned mixture 1, 61g of deionized water, and 5.8g of N-N dimethylethanolamine into the reaction kettle to form Mixture 2, then slowly add this mixture 2 into a reaction kettle filled with 114g of water-based polyester resin to form mixture 3, then weigh 9.8g of intermediate 2 and 0.21g of defoamer and put them into mixture 3 in turn according to the dosage of the formula In the middle, use a high-speed disperser to stir and disperse at 1200rpm for 50min to form intermediate one.

[0049] (3) Weigh 3.0g of diethylene glycol ether...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com