Method for extracting oat bran oil by using supercritical CO2 (Carbon Dioxide) fluid technique

A technology of oat bran oil and fluid technology, which is applied in the production of fat oil/fat and fat production, can solve the problems of low oil yield, low efficiency, inconvenient industrial application, etc., to ensure natural quality and extraction temperature close to room temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

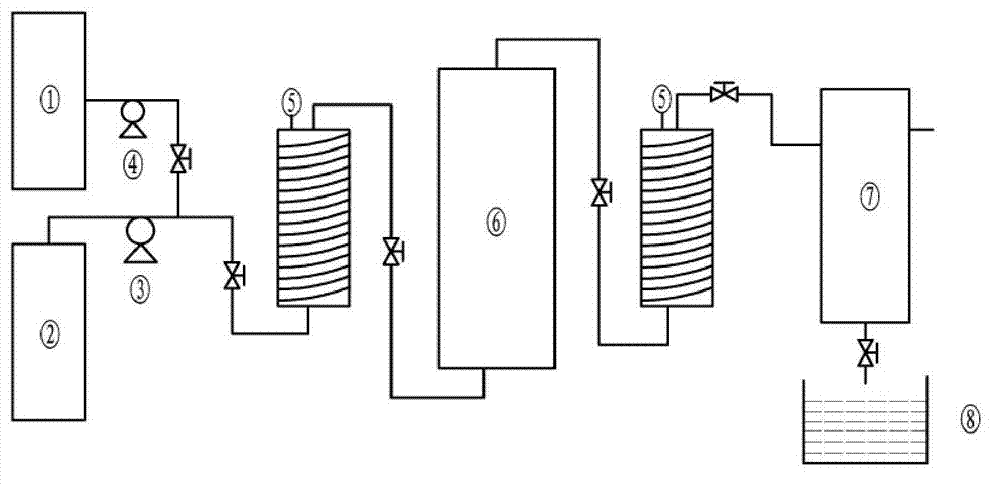

Method used

Image

Examples

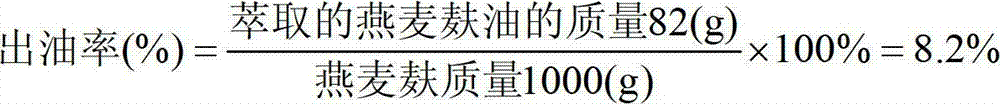

Embodiment 1

[0036] (1) Weigh 1000g oat bran sample, place it in a vacuum drying oven at 60°C, take it out every 50min, weigh it, and dry it to constant weight;

[0037] (2) Turn on the main power of the supercritical extractor, turn on the refrigeration, heat the heater, and turn on the refrigeration to the set temperature; after the extraction temperature is reached, open the kettle and put the materials into the basket, close the lid, and turn on the vacuum to pump air to the negative Pressure 0.1, CO 2 Open the cylinder and start working, adjust the extraction pressure to 27MPa, adjust the extraction temperature to 45°C, the main pump CO 2 Adjust the flow rate to 600mL / min; after working for 30 minutes, adjust the pressure of the separation tank to 6.5MPa, adjust the separation temperature to 53°C, and start to separate the oil, and the working time is 3 hours;

[0038] (3) After the extraction, the CO 2 Recover by refrigeration, until the pressure is balanced, release all the oil in...

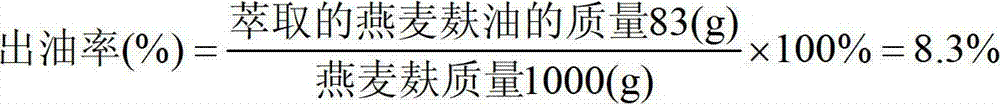

Embodiment 2

[0041] (1) Weigh 1000g oat bran sample, place it in a vacuum drying oven at 60°C, take it out every 50min, weigh it, and dry it to constant weight;

[0042] (2) Turn on the main power of the supercritical extractor, turn on the refrigeration, heat the heater, and turn on the refrigeration to the set temperature; after the extraction temperature is reached, open the kettle and put the materials into the basket, close the lid, and turn on the vacuum to pump air to the negative Pressure 0.1, CO 2 Open the cylinder and start working, adjust the extraction pressure to 28MPa, adjust the extraction temperature to 48°C, the main pump CO 2 Adjust the flow rate to 550mL / min; after working for 30 minutes, adjust the pressure of the separation tank to 7MPa, adjust the separation temperature to 55°C, and start to separate oil, and the working time is 3 hours;

[0043] (3) After the extraction, the CO 2 Recover by refrigeration, until the pressure is balanced, release all the oil in the f...

Embodiment 3

[0046] (1) Weigh 1000g oat bran sample, place it in a vacuum drying oven at 60°C, take it out every 50min, weigh it, and dry it to constant weight;

[0047] (2) Turn on the main power of the supercritical extractor, turn on the refrigeration, heat the heater, and turn on the refrigeration to the set temperature; after the extraction temperature is reached, open the kettle and put the materials into the basket, close the lid, and turn on the vacuum to pump air to the negative Pressure 0.1, CO 2 Open the cylinder and start working, adjust the extraction pressure to 26MPa, adjust the extraction temperature to 46°C, and the main pump CO 2 Adjust the flow rate to 560mL / min; after working for 30 minutes, adjust the pressure of the separation tank to 6MPa, adjust the separation temperature to 54°C, and start to separate the oil, and the working time is 3 hours;

[0048] (3) After the extraction, the CO 2 Through refrigeration recovery, to the equilibrium pressure, release all the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com