Method for constructing gravel pile of hoop of immersed tube for reinforcing soft foundation

A technology of weak foundation and construction method, which is applied in the fields of foundation structure engineering, sheet pile wall, soil protection, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] As a reinforcement technique for soft soil foundations, the reinforcement depth of hooped gravel piles or the construction technology of gravel piles may vary according to specific engineering geological conditions, so the scope of protection of the present invention is not limited to this embodiment description of.

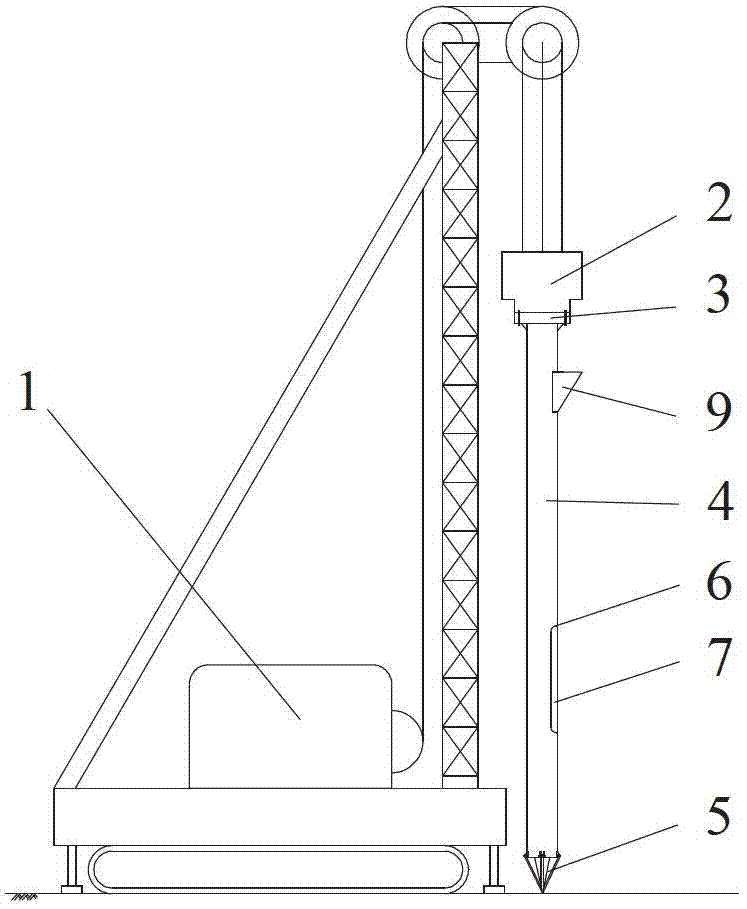

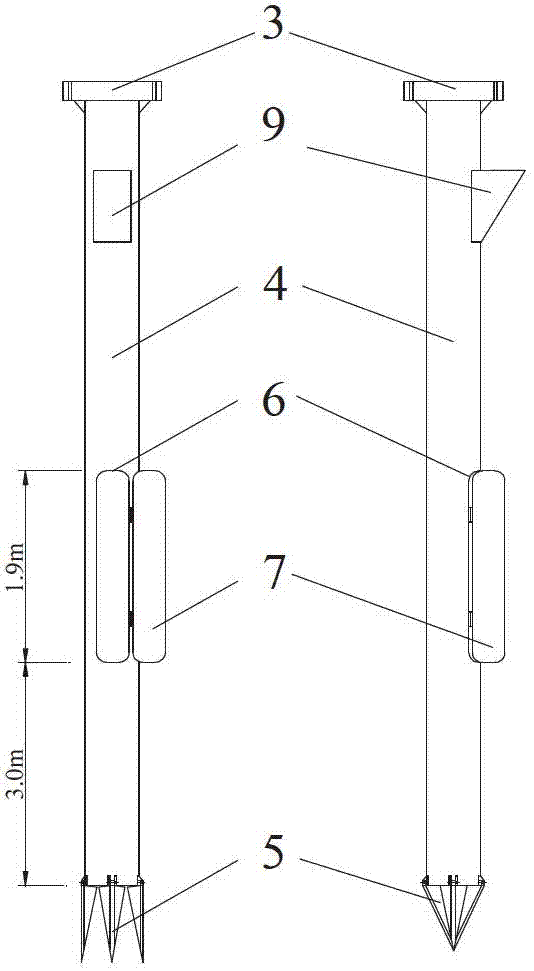

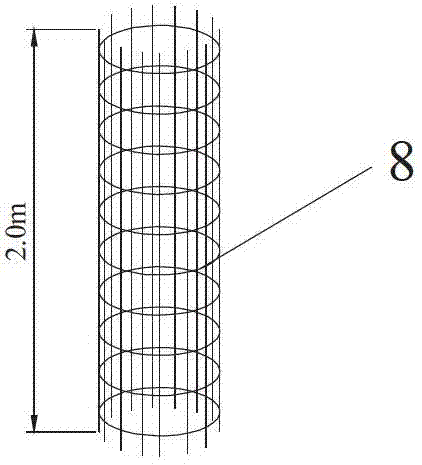

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the upper part of the vibratory pile driver 1 is provided with a vibrating head 2, and the lower part of the vibrating head 2 and the flange 3 are riveted with screws. The flange 3 is made of steel and welded with the upper end of the pile pipe 4. The pile pipe The bottom end has multiple flaps 5, and the multi-page flaps 5 are connected to the bottom of the pile tube 4 through hinges, which can be folded and closed when the pile tube 4 vibrates and sinks, and the soil will not enter the pile tube 4. When the vibration was pulled up, pushed by the crushed stones filled in the pile pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com